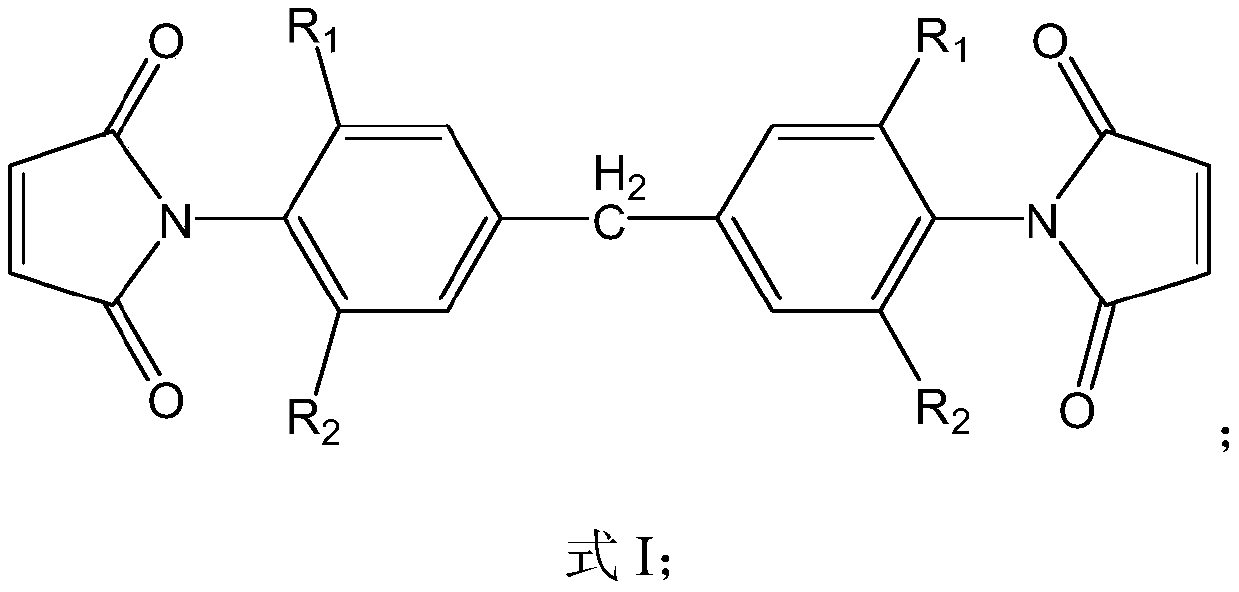

Thermosetting resin composition, prepreg comprising same, metal-foil-coated laminate and printed circuit board

A resin composition, thermosetting technology, applied in the directions of printed circuits, printed circuits, metal layered products, etc., can solve the problems of high cost, complicated preparation methods, and no consideration of dielectric properties and dielectric loss performance, and achieve high glass Effects of transition temperature, low dielectric constant, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

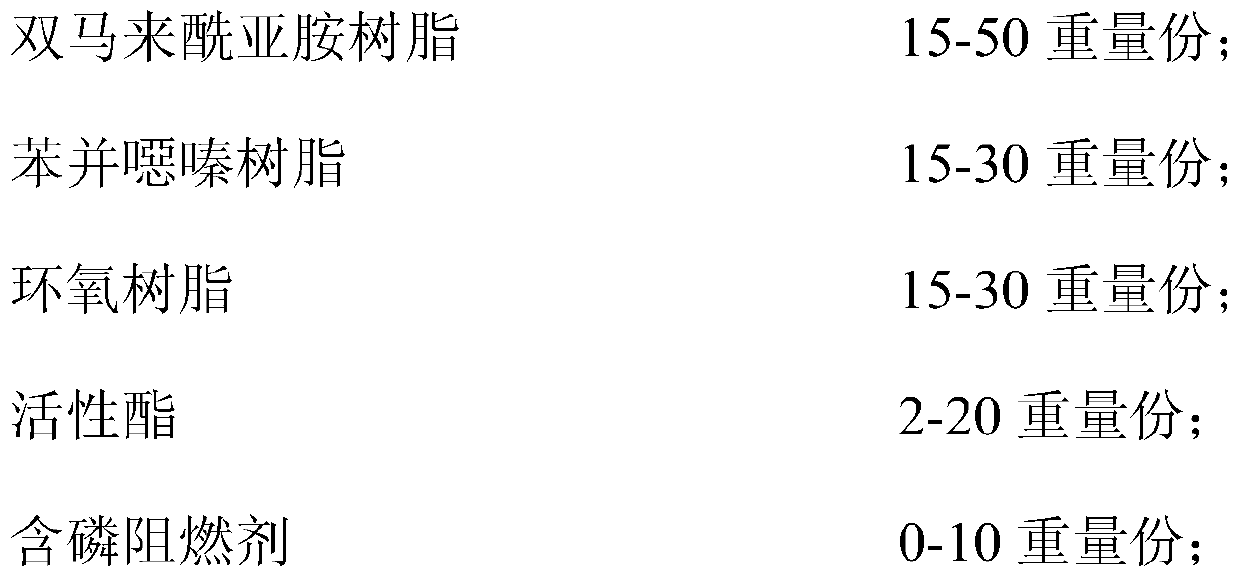

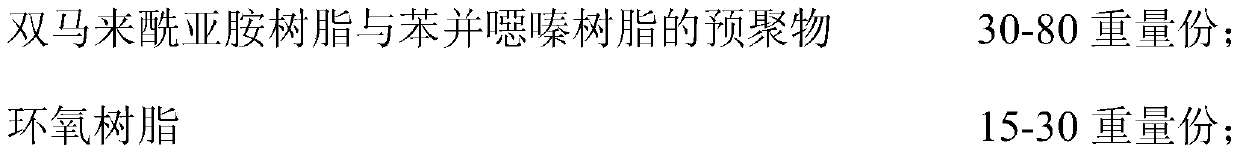

[0092] Prepare the thermosetting resin composition according to the components shown in Table 1 (the unit of raw material consumption is weight parts), and make the metal foil laminated board sample according to the following laminated board manufacturing method:

[0093] (1) React bismaleimide resin and benzoxazine resin in DMF solution at 130-160°C for 0.5-8h to obtain a prepolymer of bismaleimide resin and benzoxazine resin , and then add other components, mix evenly to obtain resin glue;

[0094] (2) Soak the resin glue into 2116 electronic grade glass fiber cloth, bake to remove the solvent and bake to a semi-cured state to obtain a prepreg suitable for the resin content, then stack a certain number of prepregs, place them on top and bottom A piece of electrolytic copper foil dedicated to copper-clad laminates is cured and laminated with a high-temperature press at 220°C / 90min to obtain copper-clad laminates.

Embodiment 5-10

[0096] Prepare a thermosetting resin composition according to the components shown in Table 1 (the unit of raw material dosage is parts by weight), and make a copper-clad laminate sample according to the following laminate production method:

[0097] (1) Mix components such as bismaleimide resin, benzoxazine resin, epoxy resin and active ester in the DMF solution of formula quantity, obtain resin glue;

[0098](2) Soak the resin glue into 2116 electronic grade glass fiber cloth, bake to remove the solvent and bake to a semi-cured state to obtain a prepreg suitable for the resin content, then stack a certain number of prepregs, place them on top and bottom A piece of electrolytic copper foil dedicated to copper-clad laminates is cured and laminated with a high-temperature press at 220°C / 90min to obtain copper-clad laminates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com