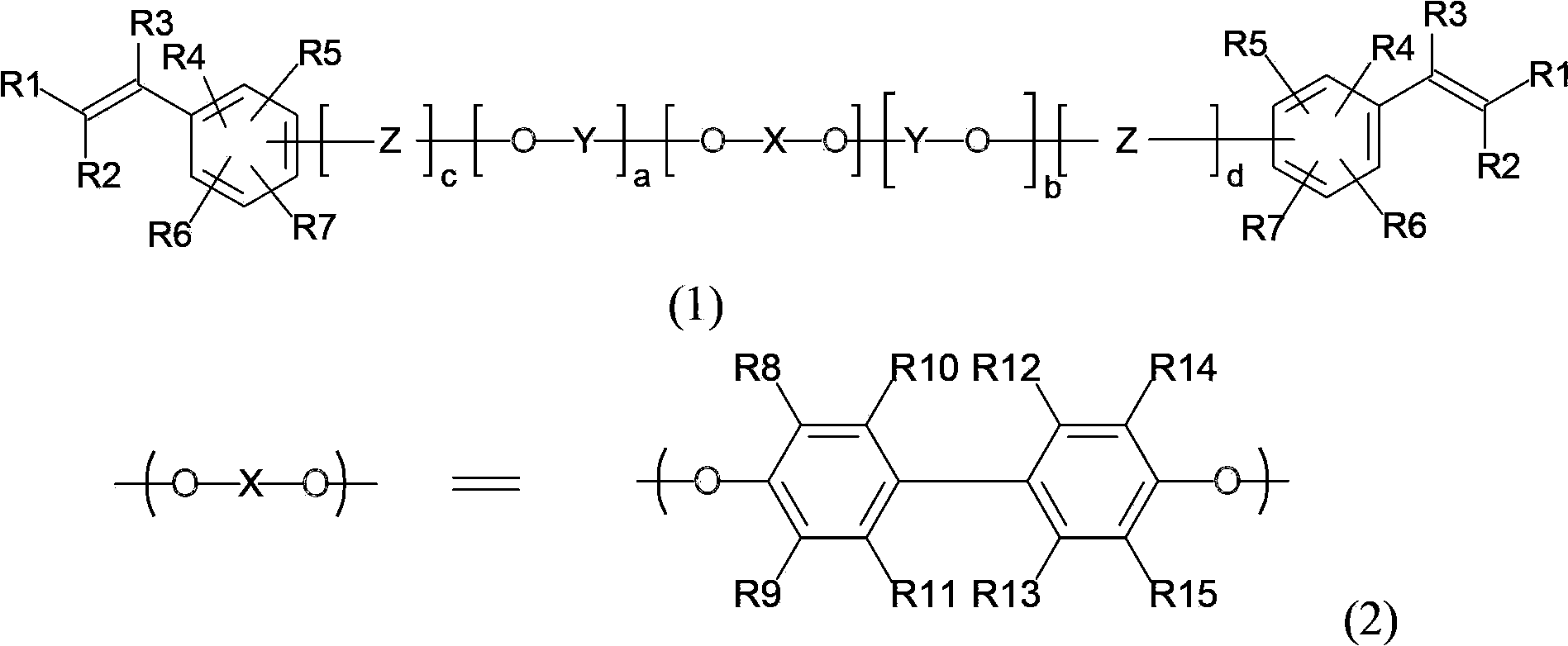

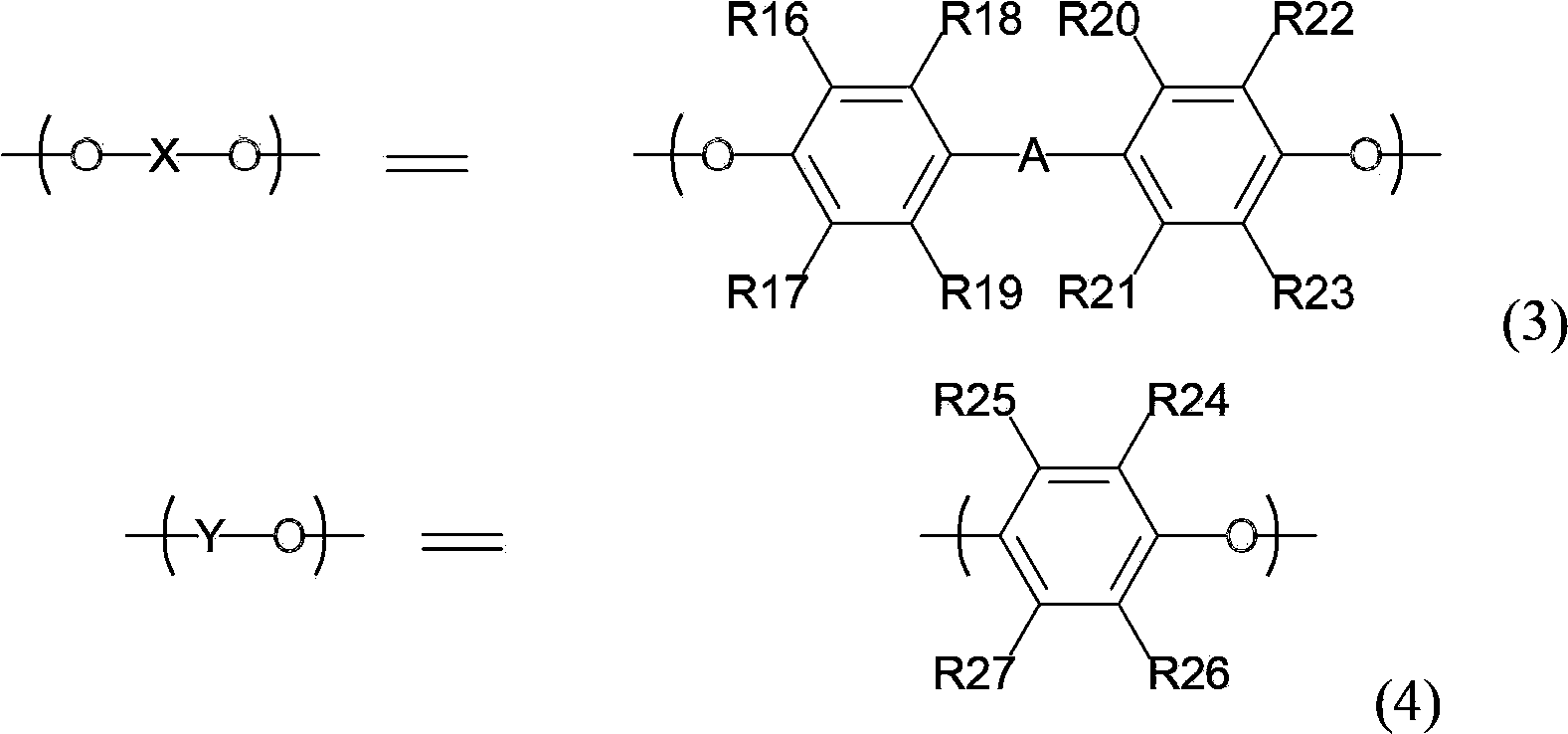

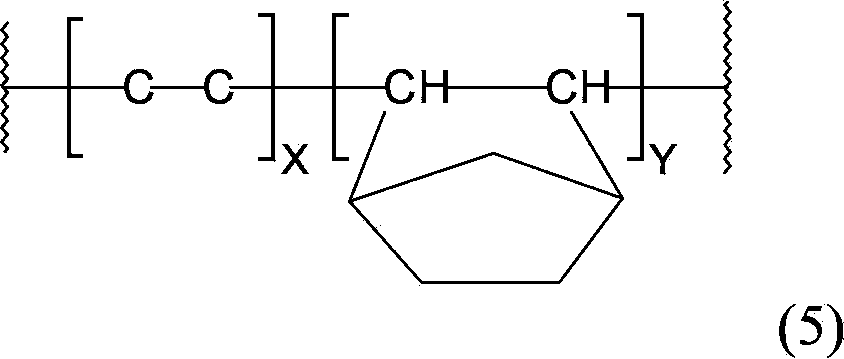

Low dielectric resin composite and copper foil base plate applying composite as well as printed circuit board

A resin composition, resin technology, applied in the direction of printed circuit, printed circuit, printed circuit parts, etc., can solve environmental pollution and other problems, achieve low dielectric properties, increase cross-linking, low dielectric constant and dielectric The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] For fully understanding purpose, feature and effect of the present invention, now by following specific embodiment, the present invention is described in detail, and explanation is as follows:

[0060] The compositions of the resin compositions of Examples 1-5 (E1-E5) and Comparative Examples 1-2 (C1-C2) are listed in Table 1, respectively. Mix the resin compositions of Examples 1 to 5 and Comparative Examples 1 to 2 in batches in a stirring tank and put them into the impregnation tank, then pass the glass fiber cloth through the above impregnation tank to make the resin composition adhere to the glass Fiber cloth, then heated and baked into a semi-cured state to obtain a semi-cured film.

[0061] For the above-mentioned prepregs prepared in batches, take four prepregs and two 18μm copper foils from the same batch, and laminate them in the order of copper foil, four prepregs, and copper foils, and then place them under vacuum conditions. The copper foil substrate is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com