Method for continuously preparing Si-B-N-O fiber by using PCS (Polycarbosilane) fiber

A si-b-n-o fiber technology, applied in the field of continuous Si-B-N-O fiber preparation, to achieve low dielectric properties, simplify the preparation process, and avoid deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) The PCS ( =1850,T m =212-226°C) placed in the melting cylinder of the melt spinning device (the spinneret hole is 200 holes, the hole diameter is 0.2μm), heated under the protection of high-purity nitrogen and degassed, at 290°C, 0.4 Spinning at a speed of 500m / min under MPa pressure to obtain continuous PCS fibers with an average fiber diameter of 12.5μm; place the PCS fibers in a non-melting furnace and heat them to 190°C in air at a heating rate of 10°C / hr , after 2 hours of heat preservation, cooled to room temperature to obtain PCS non-melting fibers.

[0015] (2) Place the prepared PCS non-melting fiber in a high-temperature furnace, vacuumize and use N 2 After replacement, heat up at a rate of 100°C / hr, and start feeding high-purity NH at a flow rate of 8ml / min / g at 200°C 3 Gas to 1000 ° C, heat preservation for 1 hour to carry out nitriding treatment to obtain nitrided fibers, and wait for the furnace temperature to drop to 60

[0016] Keep warm after 0...

Embodiment 2-4

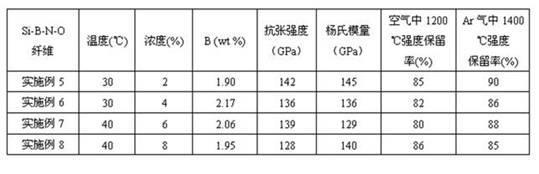

[0020] Nitriding and boriding of PCS non-melting fibers were carried out according to the method of Example 1, except that the temperatures of boriding were 800°C, 900°C, and 1000°C respectively. The properties of the obtained Si-B-N-O fibers are shown in Table 1.

[0021] Table 1. Composition and properties of Si-B-N-O fibers prepared under different preparation conditions

[0022]

Embodiment 5

[0024] The PCS infusible fiber that prepares in embodiment 1 is put into the H that concentration is 2wt% 3 BO 3 After immersing in the aqueous solution for 1 hour at 40°C, take it out, wash it with deionized water, and dry it in an oven at 100°C for 4 hours. The obtained boronized fibers were placed in a high-temperature furnace, vacuumed and treated with N 2 After replacement, heat up at a rate of 100°C / hr, and start feeding high-purity NH at a flow rate of 8ml / min / g at 200°C 3 Gas to 1000 ° C, heat preservation for 1 hour for nitriding treatment, and then pass high-purity N 2 Air blowing off residual NH 3 After degassing, the temperature was raised to 1300°C at a heating rate of 100°C / hr, and after heat preservation treatment for 1 hour, it was cooled to room temperature to obtain Si-B-N-O fibers.

[0025] The composition of the obtained fiber is Si: 54.56wt%, B: 1.90wt%, N: 29.85wt%, O: 12.26wt% C: 0.16wt%, the average fiber diameter is 10.6μm, and the average tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com