Aliphatic polycarbonate alloy material

A polycarbonate and alloy material technology, applied in the direction of conjugated synthetic polymer rayon, cellulose/protein conjugated rayon, etc., can solve the problem that the heat resistance temperature of PPC and the high temperature of blend materials cannot be fundamentally improved. Poor performance, insufficient low temperature toughness and other problems, to achieve the effect of improving compatibility and interface of two phases, increasing thermal degradation temperature, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] After PPC was dried in a vacuum oven at 45-50°C for 24 hours, and CAB was dried in a vacuum oven at 80°C for 24 hours, the PPC / CAB was weighed according to the mass ratio PPC / CAB=95g / 5g, mixed and stirred at room temperature and then added to the dense In the mixing machine, the temperature of the internal mixer is 190° C., the screw speed is set at 100 rpm, and the material is discharged after 5 minutes of internal mixing.

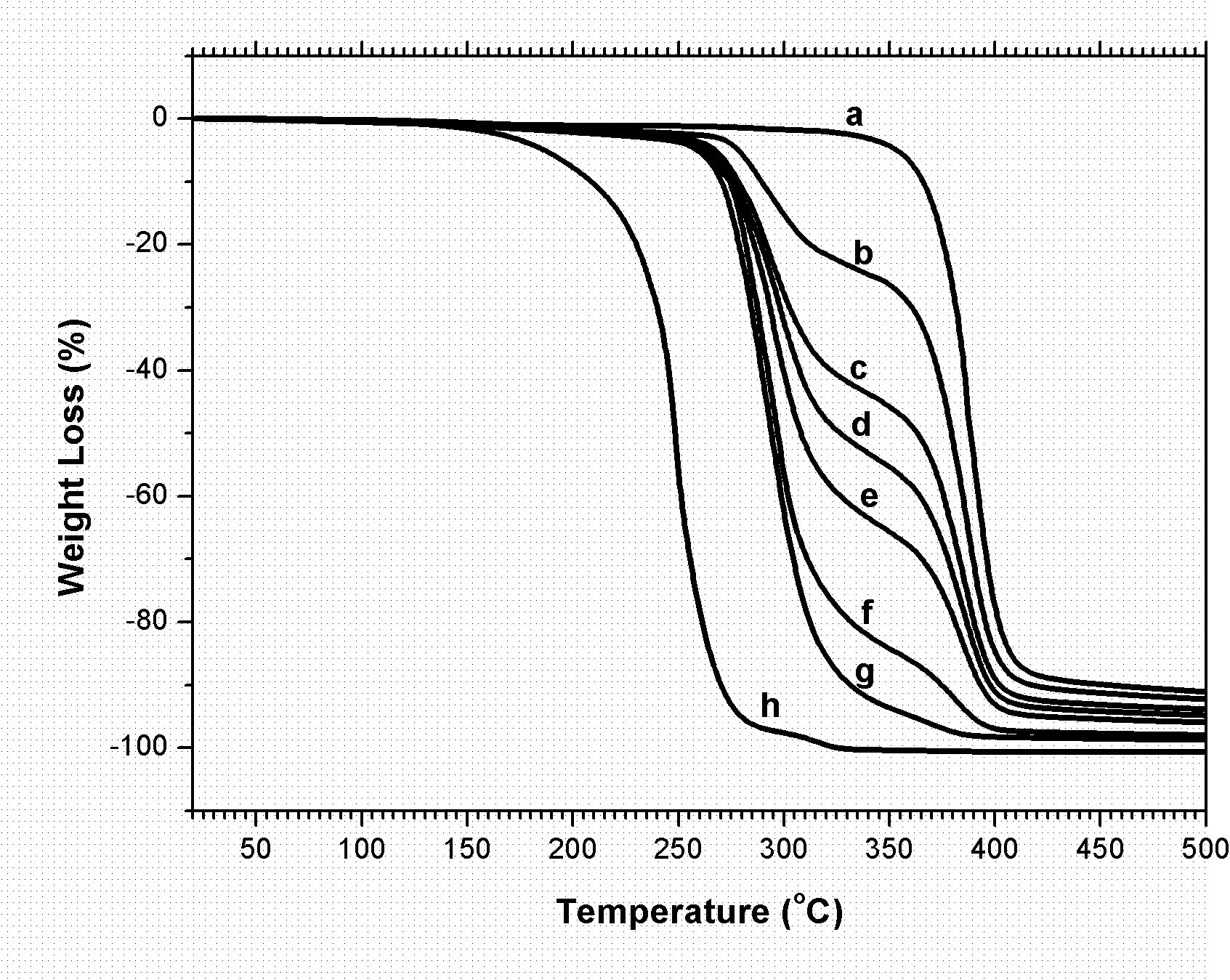

[0034] The above mixed sample was hot-pressed into a sheet with a thickness of 1mm in a hot press at 190°C, and the thermal stability was tested. Using the SII-TGA analyzer, in an air atmosphere, the heating rate was 20°C / min, and the temperature range was measured 50-550°C. see resultsfigure 1 The curve in (g) CAB / PPC=5 / 95.

Embodiment 2-7

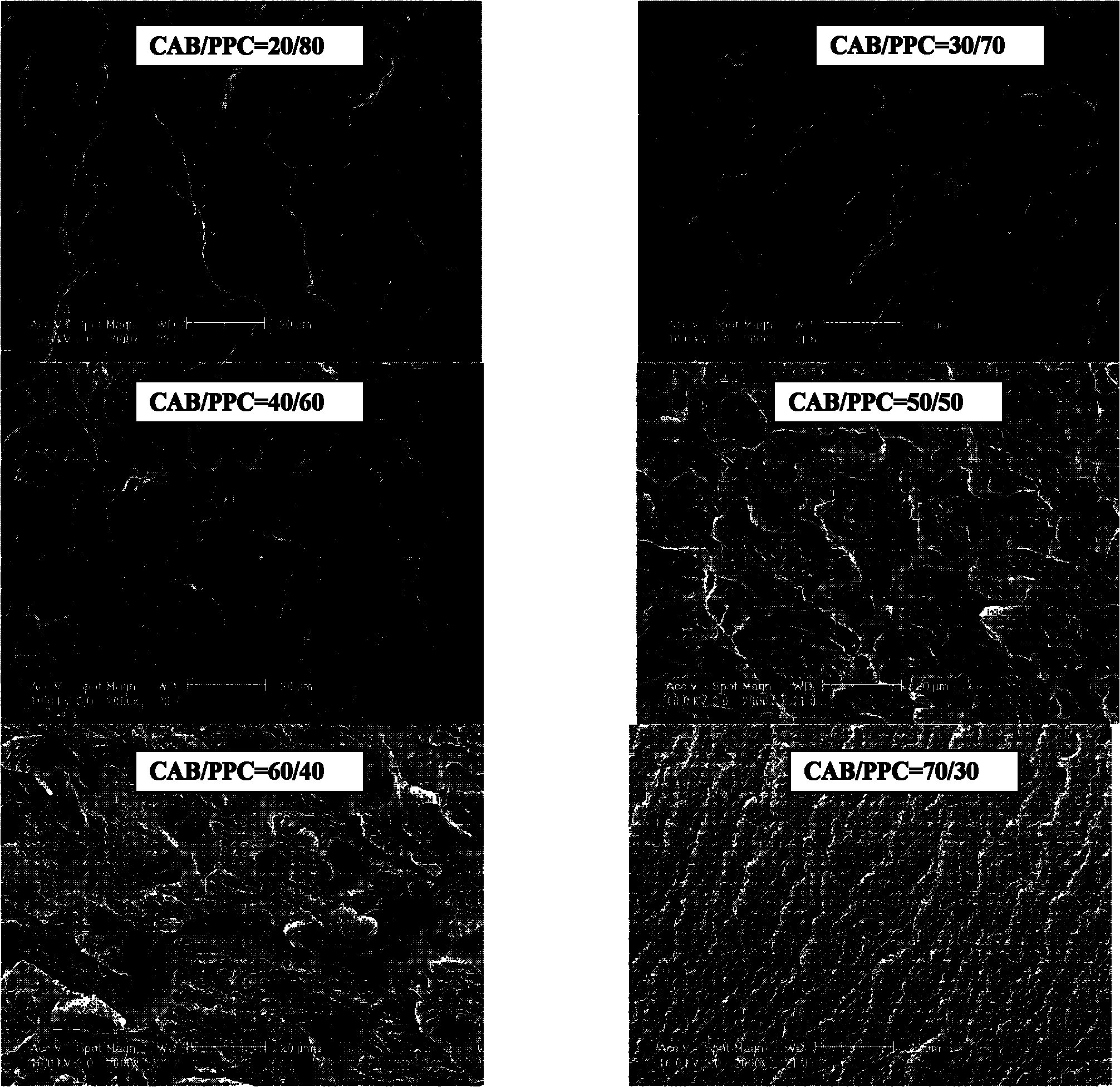

[0036] PPC was dried in a vacuum oven at 45-50°C for 24 hours, CAB was dried in a vacuum oven at 80°C for 24 hours, and the samples were weighed according to the mass ratio of PPC / CAB shown in Table 1, mixed and stirred at room temperature and then added to the internal mixer In the process, the temperature of the internal mixer is 190°C, the screw speed is set at 100 rpm, and the material is discharged after 5 minutes of internal mixing.

[0037] The above-mentioned kneaded sample was hot-pressed into a sheet having a thickness of 1 mm in a hot press at 190° C., and various tests were performed.

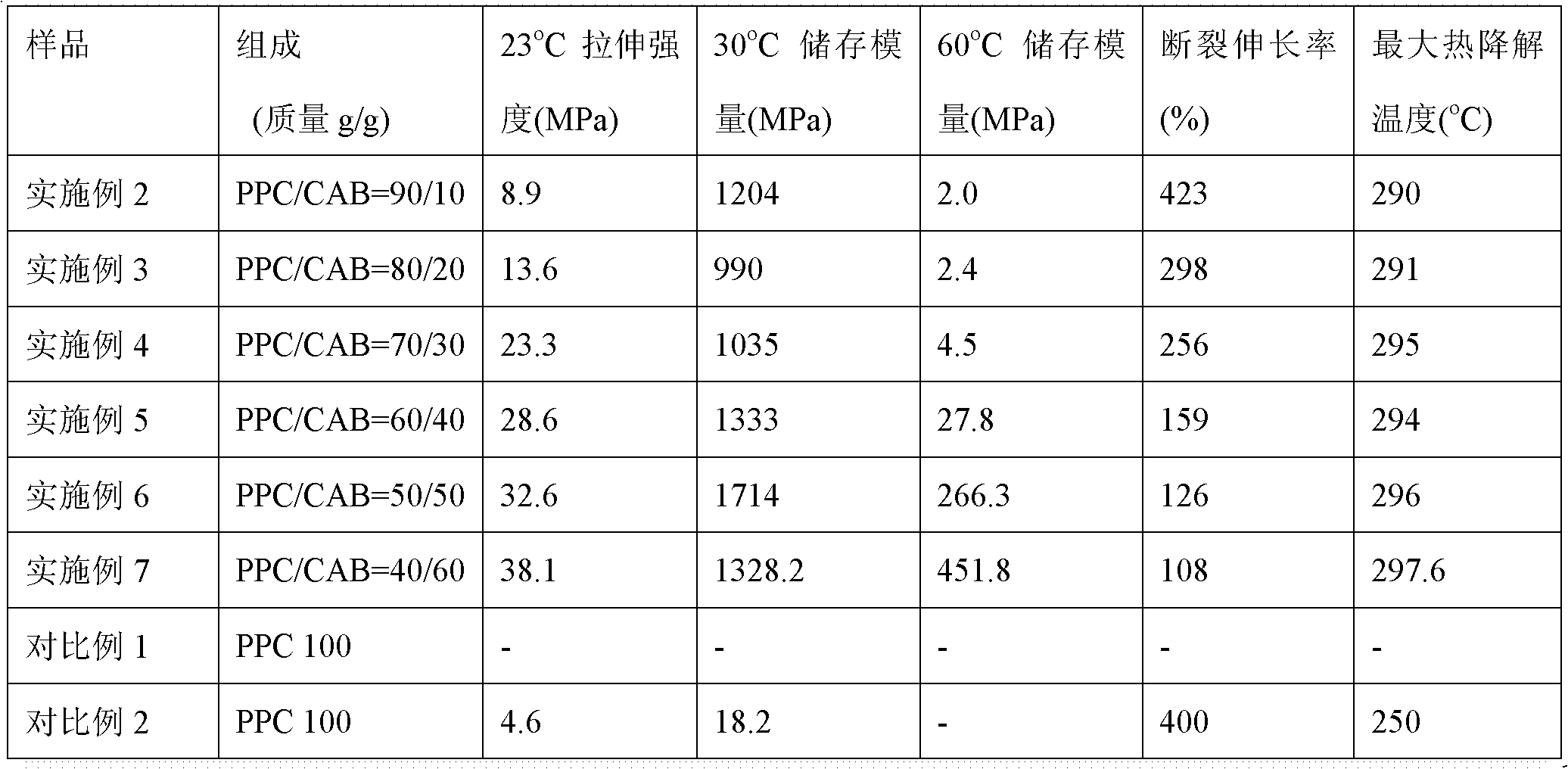

[0038] The above-mentioned samples were tested for tensile properties, using dumbbell-shaped samples, and tested according to ASTM D412-80. The tensile testing machine was Tensilon UMT-300, the tensile speed was 10mm / min, and the tensile test conditions were temperature 23°C. The humidity is 50%, and the results are shown in Table 1.

[0039] In order to test the thermal stability ...

Embodiment 8

[0046] After PEC was dried in a vacuum oven at 35-40°C for 24 hours, and CAB was dried in a vacuum oven at 80°C for 24 hours, the PEC / CAB was weighed according to the mass ratio PPC / CAB=50g / 50g, mixed and stirred at room temperature and then added to the dense In the mixing machine, the temperature of the internal mixer is 190° C., the screw speed is set at 100 rpm, and the material is discharged after 5 minutes of internal mixing.

[0047] The above mixed sample was hot-pressed into a sheet with a thickness of 1mm in a hot press at 190°C, and the thermal stability was tested. Using the SII-TGA analyzer, in an air atmosphere, the heating rate was 20°C / min, and the temperature range was measured 50-550°C. The measurement results show that the maximum thermal degradation temperature of pure PEC is 220℃, and the maximum thermal degradation temperature of the blend is significantly increased to 262℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com