High-plant high-performance polylactic acid alloy material

A technology of alloy materials and polylactic acid, which is applied in the field of polymer technology and ecological environment materials, can solve the problem of size reduction of dispersed phase micro-domains, and achieve the effects of size reduction, reduced interfacial tension, and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

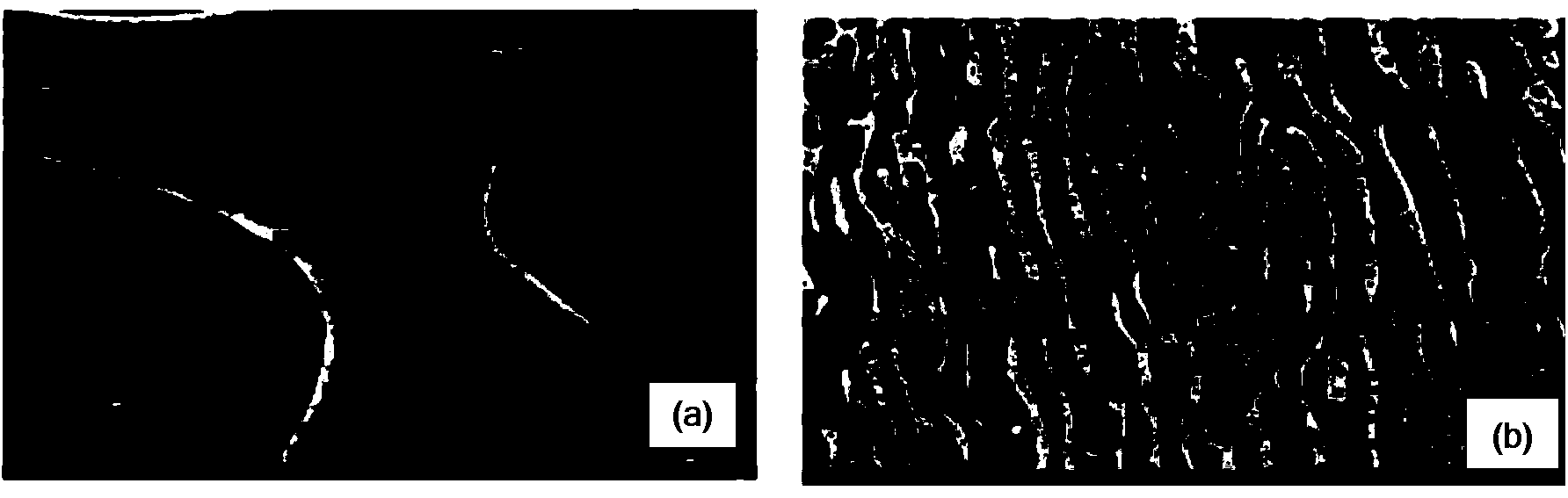

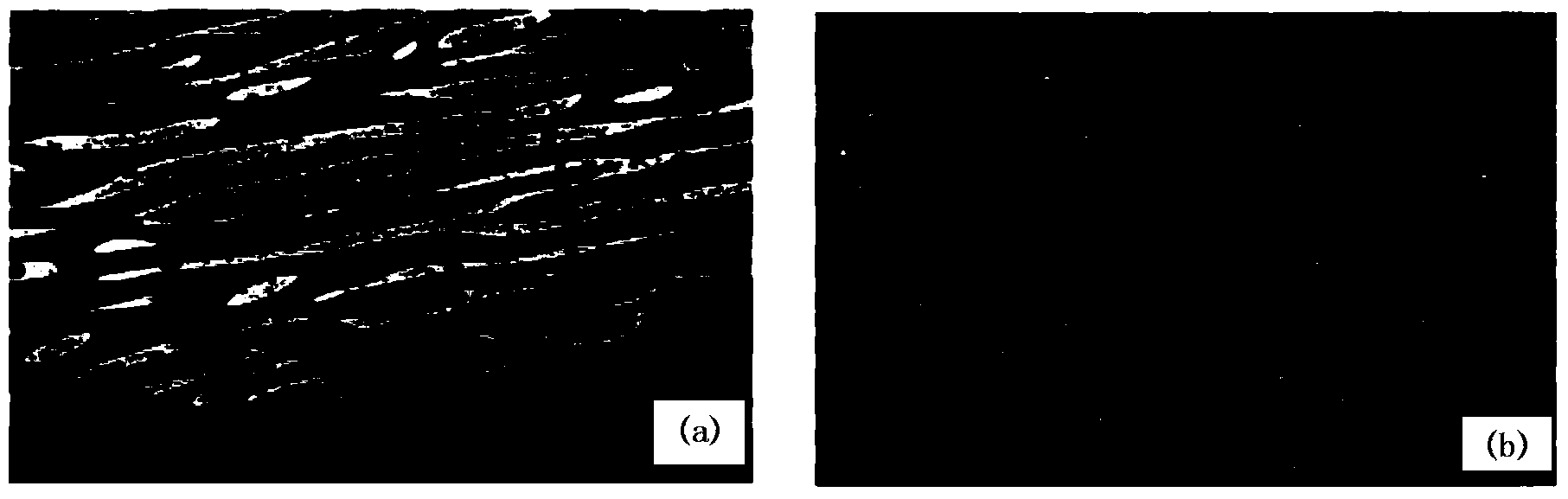

[0038] After drying polylactic acid, polycarbonate and high-efficiency comb-type compatibilizer in a vacuum oven at 80°C, 100°C, and 50°C for 24 hours, 30g of polylactic acid, 70g of polycarbonate, and 5g of high-efficiency comb-type compatibilizer, After mixing and stirring at room temperature, add it to the internal mixer at one time. The temperature of the internal mixer is 240 ° C, the screw speed is set at 50 rpm, and the melt blending is performed for 5 minutes to obtain a high-vegetative high-performance polylactic acid alloy material.

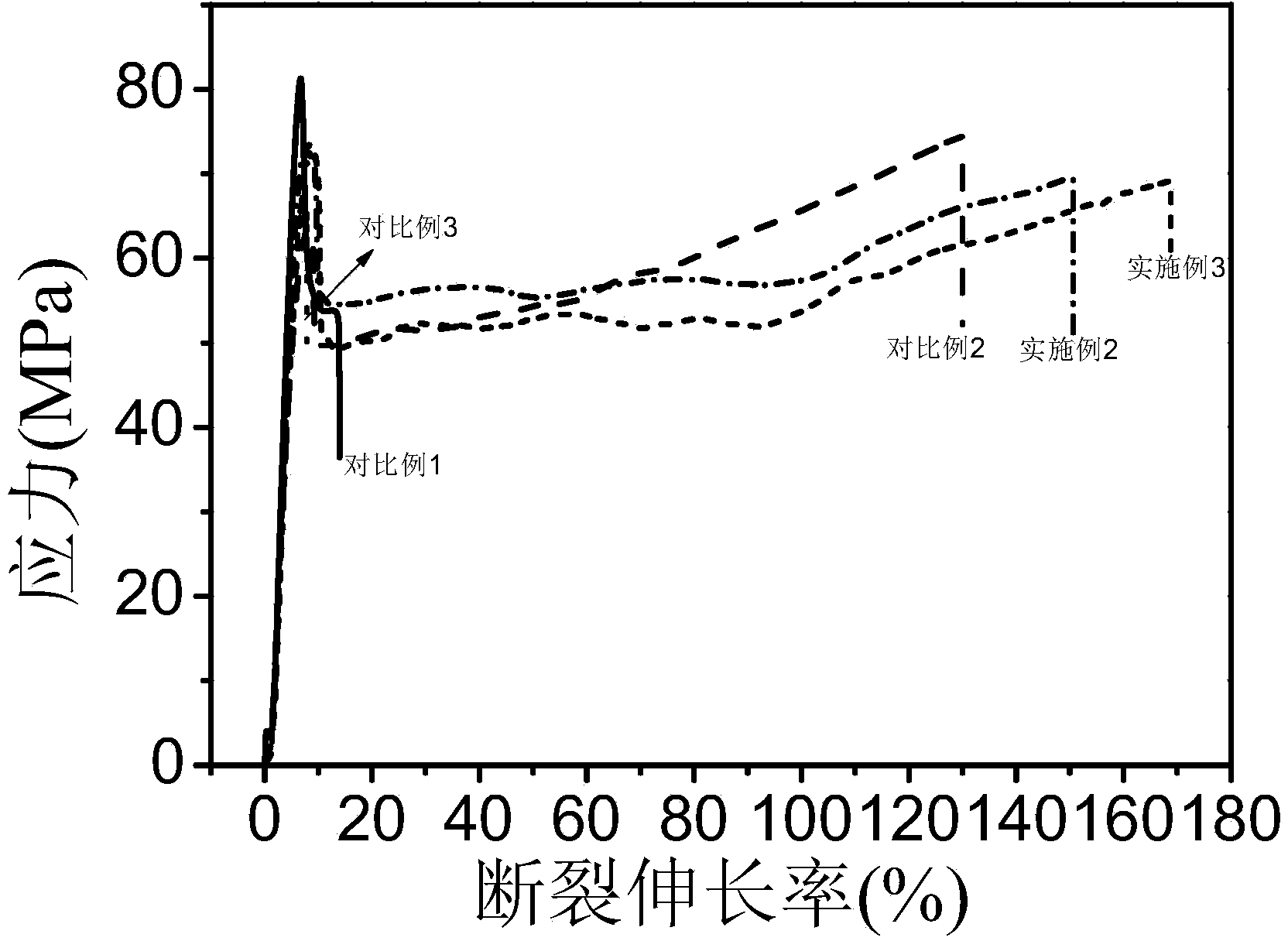

[0039] The polylactic acid alloy material prepared in Example 1 was hot-pressed into sheets in a hot press at 240°C, and a standard test sample was prepared with a standard dumbbell-shaped punching knife for performance testing. The results are shown in Table 1.

Embodiment 2

[0041] After drying polylactic acid, polycarbonate and high-efficiency comb-type compatibilizer in a vacuum oven at 80°C, 100°C, and 50°C for 24 hours, 50g of polylactic acid, 50g of polycarbonate, and 5g of high-efficiency comb-type compatibilizer, After mixing and stirring at room temperature, add it to the internal mixer at one time. The temperature of the internal mixer is 240 ° C, the screw speed is set at 50 rpm, and the melt blending is performed for 5 minutes to obtain a high-vegetative high-performance polylactic acid alloy material.

[0042] The polylactic acid alloy material prepared in Example 2 was hot-pressed into sheets in a hot press at 240°C, and a standard test sample was prepared with a standard dumbbell-shaped punching knife for performance testing. The results are shown in Table 1.

Embodiment 3

[0044] After drying polylactic acid, polycarbonate and high-efficiency linear compatibilizer in a vacuum oven at 80°C, 100°C, and 50°C for 24 hours, 50g of polylactic acid, 50g of polycarbonate, and 5g of high-efficiency linear compatibilizer were mixed at room temperature After mixing and stirring, add it to the internal mixer at one time. The temperature of the internal mixer is 240 ° C, the screw speed is set at 50 rpm, and the melt blending is performed for 5 minutes to obtain a high-vegetative high-performance polylactic acid alloy material.

[0045] The polylactic acid alloy material prepared in Example 3 was hot-pressed into sheets in a hot press at 240°C, and a standard test sample was prepared with a standard dumbbell-shaped punching knife for performance testing. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com