Polycrystal diamond hard alloy complex sheet of surface groove with lack Co area

A polycrystalline diamond and cemented carbide technology, which is applied in drilling equipment, earth-moving drilling, drill bits, etc., can solve the problems of improving the thermal stability of the composite sheet, not easy to extract Co, and the composite sheet failure, etc., and achieves increased use. Temperature range, cracking prevention, and the effect of reducing the peeling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

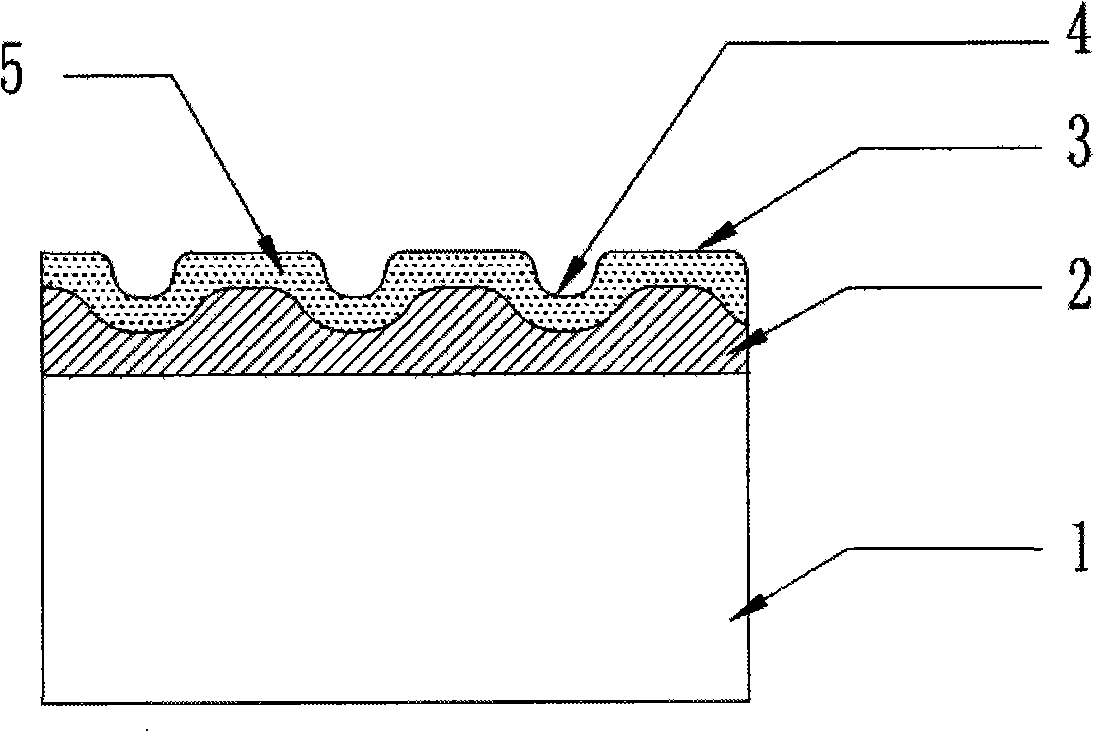

[0026] Such as figure 1 As shown, the polycrystalline diamond carbide composite sheet composed of cemented carbide layer 1 and diamond layer 2 with groove 4 is soaked in HNO 3 : 10vol%; HCl: 40vol%; water: in the solution prepared by the remainder, after chemical reaction to remove Co, the entire diamond layer including the surface of the groove 4 and the surface of the platform 3 between the adjacent grooves is formed Co-deficient regions on the surface5.

Embodiment 2

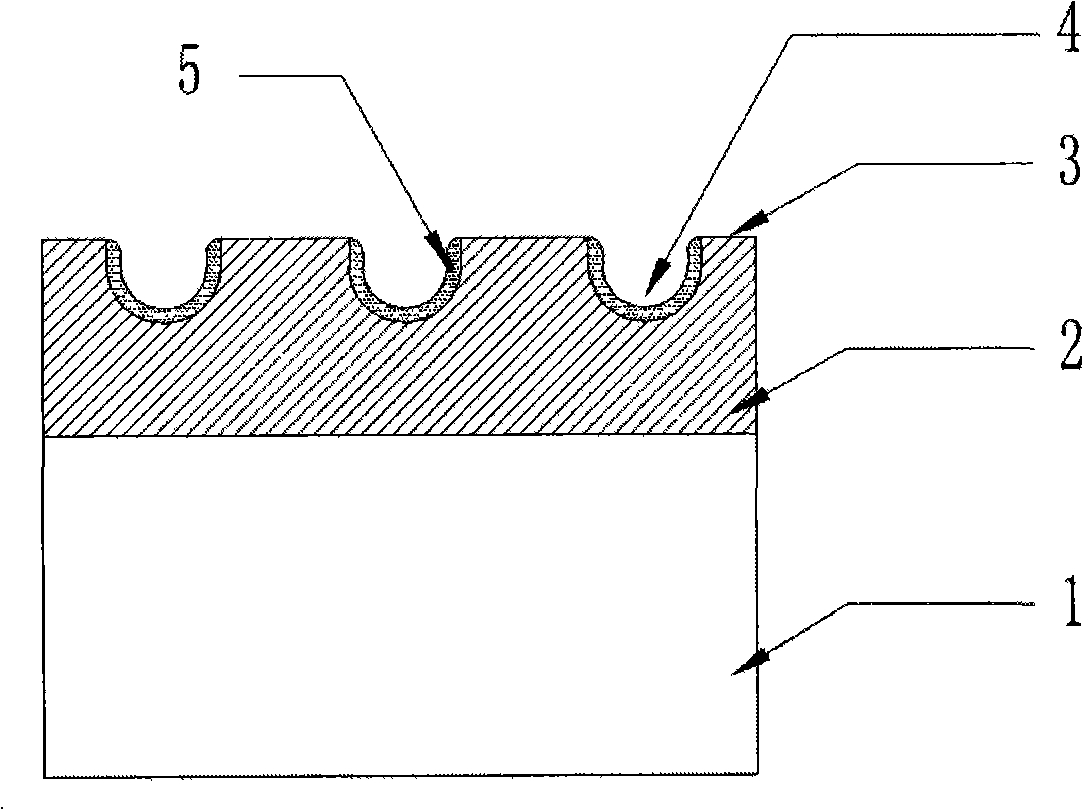

[0028] Such as figure 2 As shown, the polycrystalline diamond hard alloy composite sheet made of hard alloy layer 1 and diamond layer 2 is covered by covering, so that only the groove 4 part of the polycrystalline diamond hard alloy composite sheet is exposed, and then it is soaked in the HNO 3 : 15vol%; HCl: 45vol%; water: the remainder is configured in the solution, after chemical reaction to remove Co, a Co-deficient region 5 on the inner surface of the groove 4 is formed.

Embodiment 3

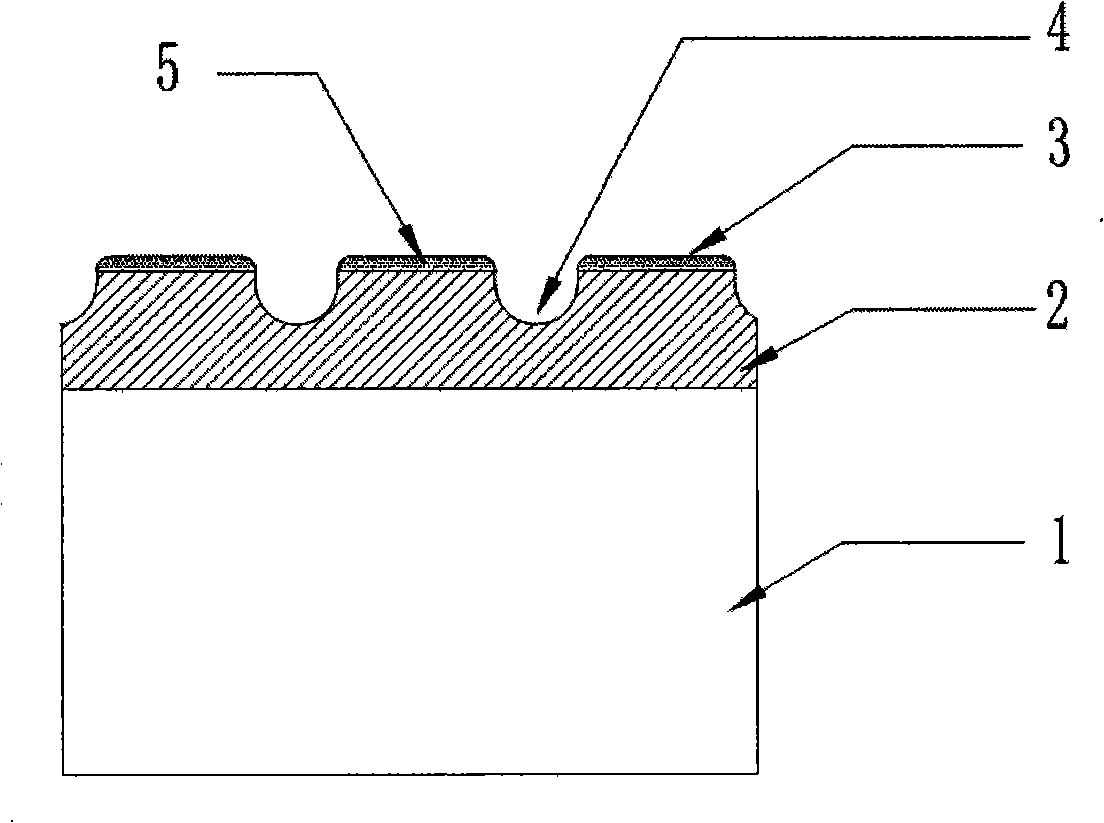

[0030] Such as image 3 As shown, the polycrystalline diamond cemented carbide composite sheet composed of cemented carbide layer 1 and polycrystalline diamond layer 2 covers the groove 4 in a certain way, so that the part of the surface of the polycrystalline diamond composite sheet without grooves is exposed. Then soak it in HNO 3 : 20vol%; HCl: 50vol%; water: the remaining amount is configured in the solution, after the chemical reaction is carried out to remove Co, the surface part of the platform 3 between two adjacent grooves 4 on the polycrystalline diamond layer forms a Co-deficient region 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com