Preparation process of polycrystalline diamond composite sheet with mixed particle size

A polycrystalline diamond, mixed particle size technology, applied in diamond and other directions, can solve the problems of unbalanced wear resistance and strength, unreasonable diamond particle size, poor single parameter, etc., to avoid insufficient sealing, reduce pressure difference, and improve wear and tear. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

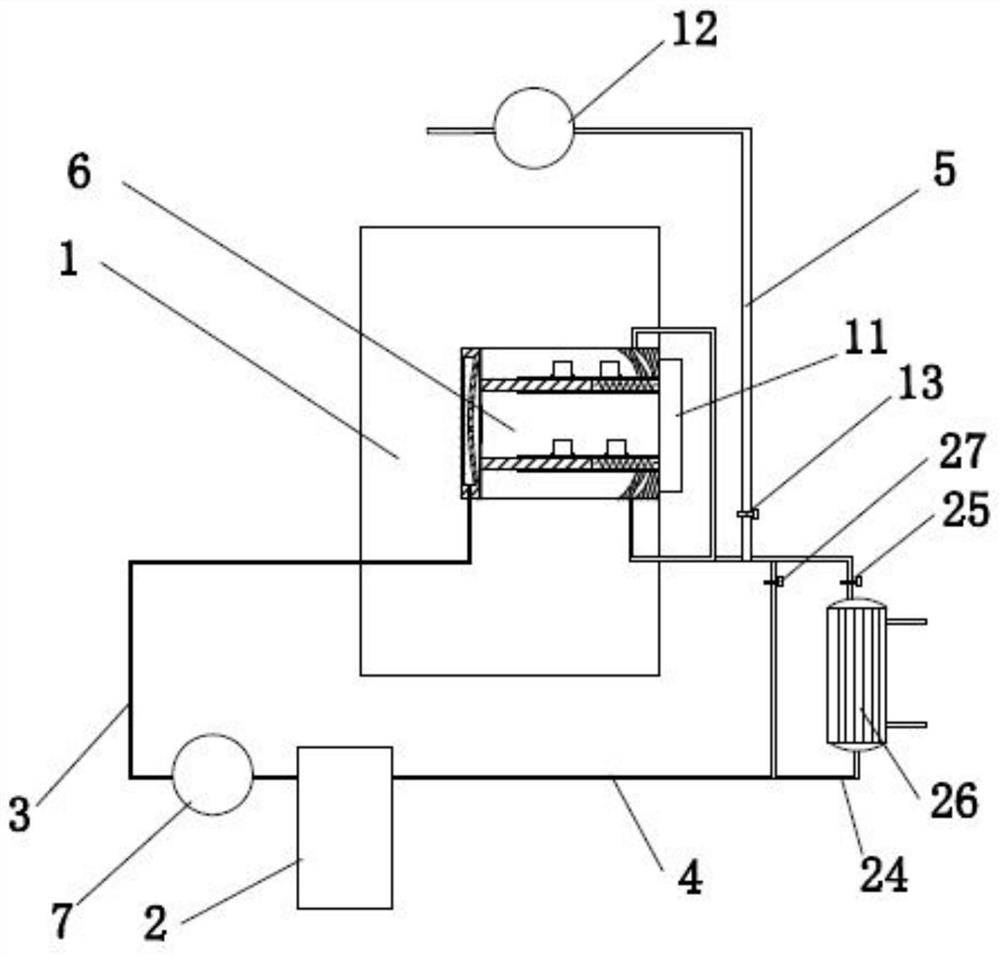

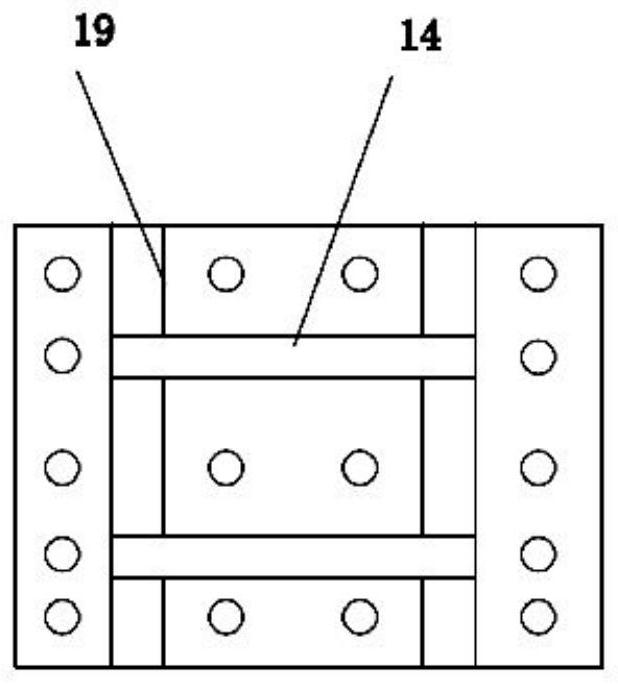

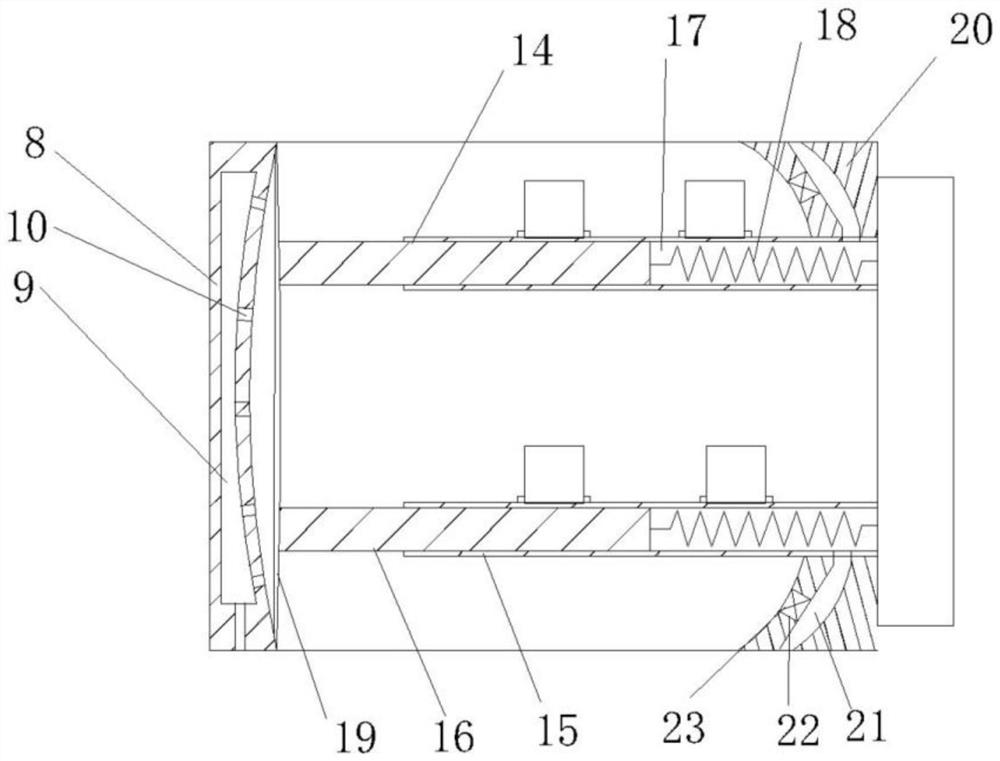

[0037] A polycrystalline diamond composite sheet of mixed particle size provided by the present invention comprises several uniformly distributed cemented carbide layers arranged on the upper surface, a composite transition layer arranged on the surface of the cemented carbide layer, and the shape of the bottom and the cemented carbide layer Complementary polycrystalline diamond layers.

Embodiment 2

[0039] A kind of preparation technology of polycrystalline diamond composite sheet of mixed particle size provided by the present invention, it comprises the following steps:

[0040] 1) Preparation of cemented carbide parts: select cemented carbide mixture, wherein the main particle size of the powder is 15 microns, and a plurality of special-shaped combined molds are arranged on the surface, and a flow warm pressing molding process is adopted, the molding pressure is 600MPa, and the molding temperature is 160°C; degrease and sinter the molded parts, the sintering temperature is 1300°C, and the time is 12 hours to obtain hard alloy parts;

[0041] 2) Preparation of composite transition layer: adopt CVD method to deposit molybdenum on the cemented carbide groove and surface, and the deposition thickness is 10 microns;

[0042] 3) Spherical micro-diamonds are selected, which include the first diamond powder with a particle size of 5 microns, the second diamond powder with a par...

Embodiment 3

[0048] A kind of preparation technology of polycrystalline diamond composite sheet of mixed particle size provided by the present invention, it comprises the following steps:

[0049] 1) Preparation of cemented carbide parts: select cemented carbide mixture, wherein the main particle size of the powder is 21 microns, and a plurality of special-shaped combined molds are arranged on the surface, and the flowing warm pressing molding process is adopted, the molding pressure is 800MPa, and the molding temperature is 180°C; degrease and sinter the molded parts, the sintering temperature is 1500°C, and the time is 16 hours to obtain hard alloy parts;

[0050] 2) Preparation of composite transition layer: adopt CVD method to deposit molybdenum on the cemented carbide groove and surface, and the deposition thickness is 12 microns;

[0051] 3) Select spherical micro-diamond for use, which includes the first diamond powder with a particle size of 7 microns, the second diamond powder wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com