Optical fiber coupling vertical-cavity surface emitting laser with power monitoring function

A vertical cavity surface emission, fiber coupling technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as inconvenience in practical use, the chip does not integrate a power detection chip, affecting high-speed modulation performance, etc., to improve the operating temperature range. , the effect of increasing temperature stability and structural stability, increasing temperature stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

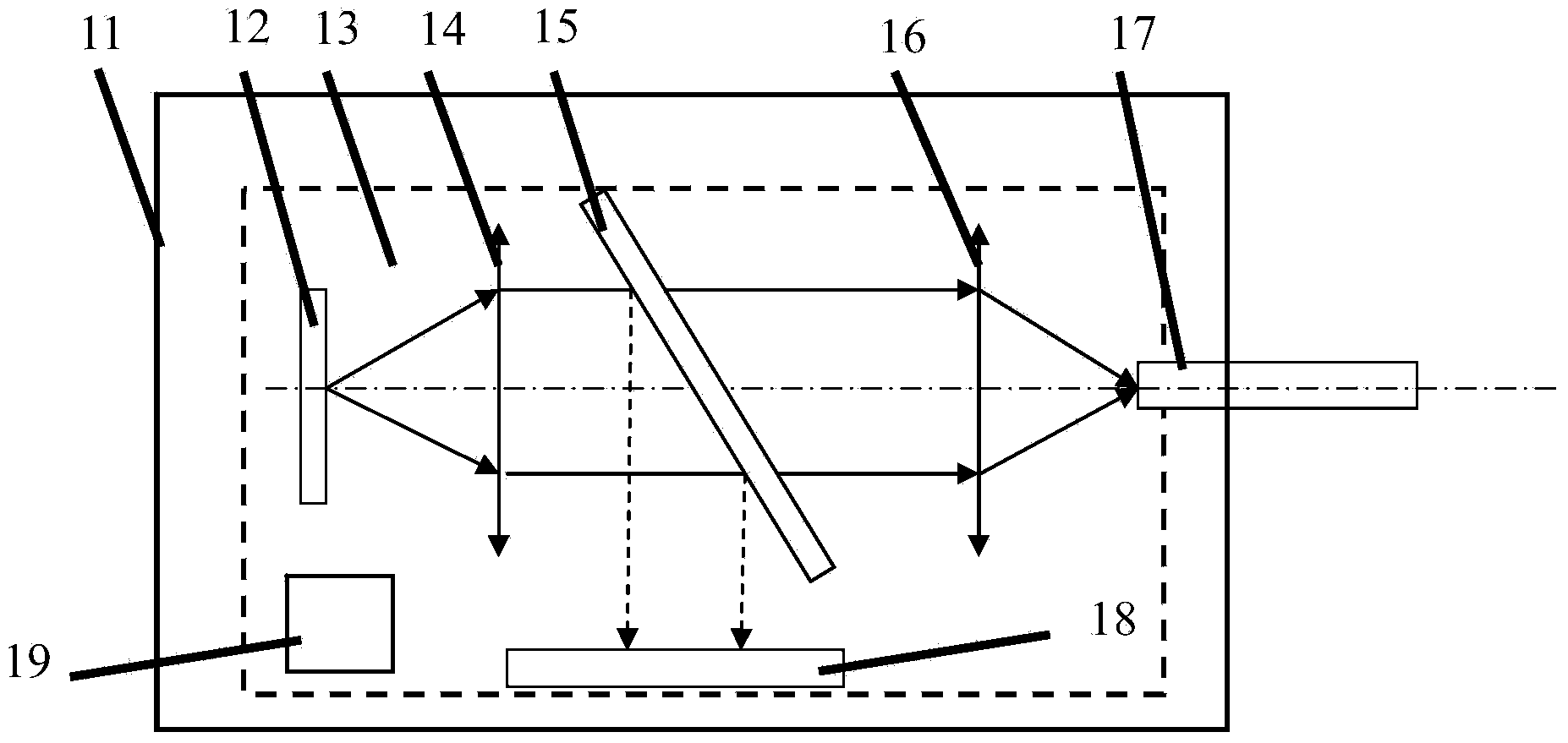

[0016] see first figure 1 , figure 1 It is a schematic structural diagram of Embodiment 1 of the present invention; this embodiment has a fiber-coupled vertical cavity surface emitting laser with power monitoring, including a laser housing 11, a vertical cavity surface emitting laser 12, a semiconductor cooler 13, a collimating lens 14, and a beam splitter 15. Coupling lens 16, coupling fiber assembly 17, power detector 18 and thermistor 19. The beam splitter 15 is a transmission type, the transmitted light is greater than the reflected light (reflected light accounts for about 1-2%), the semiconductor cooler 13 is welded to the inner bottom surface of the laser tube shell 11 by high temperature solder, and the vertical cavity surface emitting laser 12 Fixed on the upper surface of semiconductor refrigerator 13 or excessive heat sink by high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com