Carbon/aluminum composite cathode foil for solid aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor, aluminum composite technology, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors and other directions, can solve the problems of low specific capacitance, complex preparation process, safety and environmental protection, etc. Simple, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

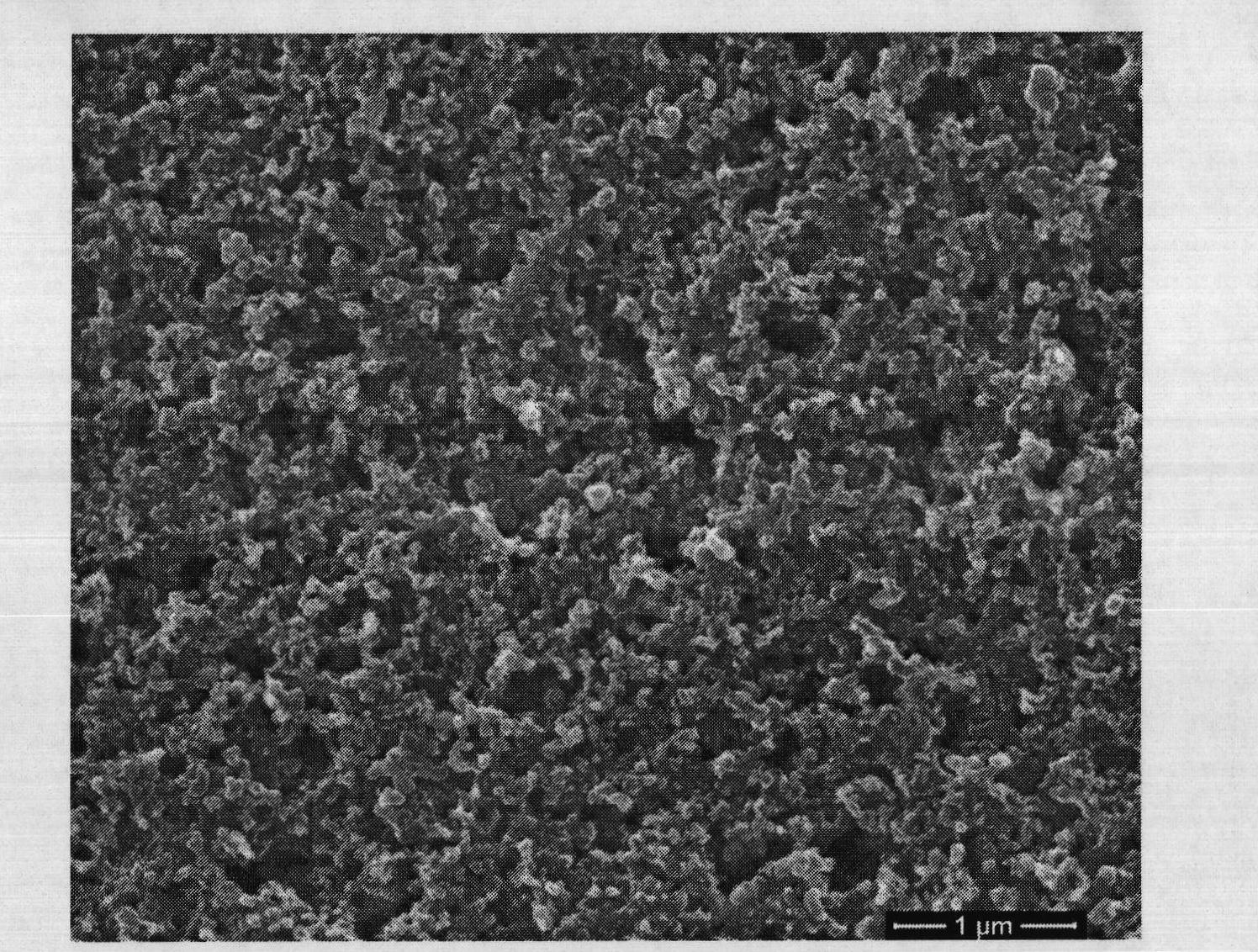

[0019] A carbon / aluminum composite cathode foil for solid aluminum electrolytic capacitors and a preparation method thereof: the mass ratio of conductive carbon black, triolein, paraffin and absolute ethanol is 1: (0.0001-0.001): (0.01-0.05 ): (50-100) for batching, first mix the conductive carbon black, triolein and paraffin wax, then add absolute ethanol and stir to make a slurry.

[0020] The prepared slurry is evenly coated on the surface of the pretreated aluminum foil by a coating method, and the thickness of the carbon layer after drying is 10-20 μm. Put the aluminum foil coated with the slurry into the vacuum furnace, and when the vacuum degree is 10 -2 ~10 -1 Pa and temperature are kept at 300-450° C. for 20-40 hours, and naturally cooled to room temperature in a vacuum furnace to prepare a carbon / aluminum composite cathode foil for a solid aluminum electrolytic capacitor.

[0021] The specific capacitance of the carbon / aluminum composite cathode foil for solid alum...

Embodiment 2

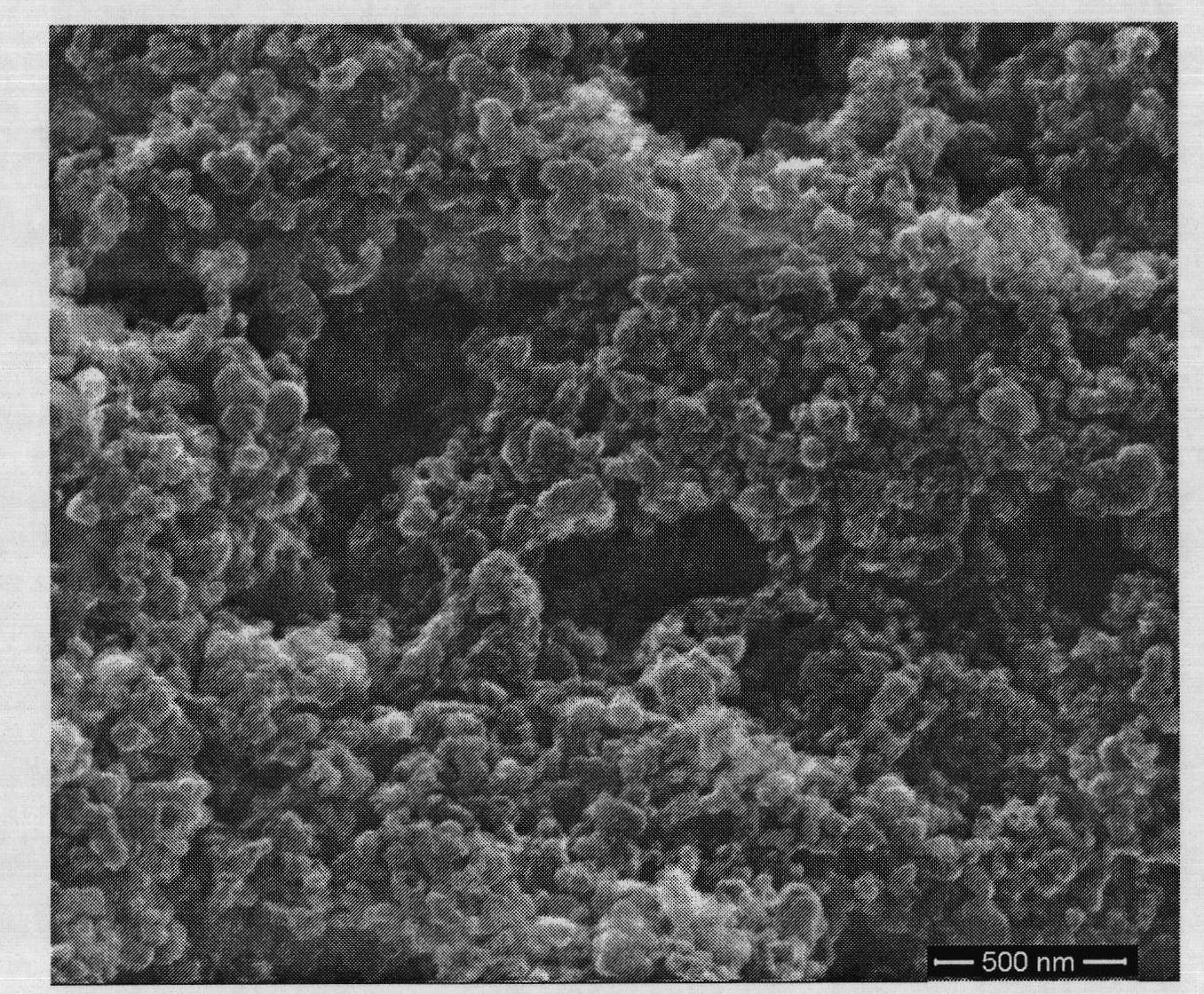

[0023] A carbon / aluminum composite cathode foil for solid aluminum electrolytic capacitors and a preparation method thereof: the mass ratio of conductive carbon black, carbon black dispersant, polyvinyl alcohol and water is 1: (0.001-0.005): (0.05-0.1) : (10-100) for batching, first mix the conductive carbon black, carbon black dispersant and polyvinyl alcohol, then add water and stir to make a slurry.

[0024] The prepared slurry is evenly coated on the surface of the pretreated aluminum foil by a spraying method, and the thickness of the carbon layer after drying is 20-30 μm. Then put the aluminum foil coated with the slurry into the vacuum furnace, at a vacuum of 10 -3 ~10 -2 Pa and temperature at 450-550°C for 15-30 hours, naturally cooled to room temperature in a vacuum furnace, then out of the furnace, and at 100-200°C and normal pressure for 0.5-3 hours to prepare carbon for solid aluminum electrolytic capacitors / Aluminum composite cathode foil.

[0025] The specif...

Embodiment 3

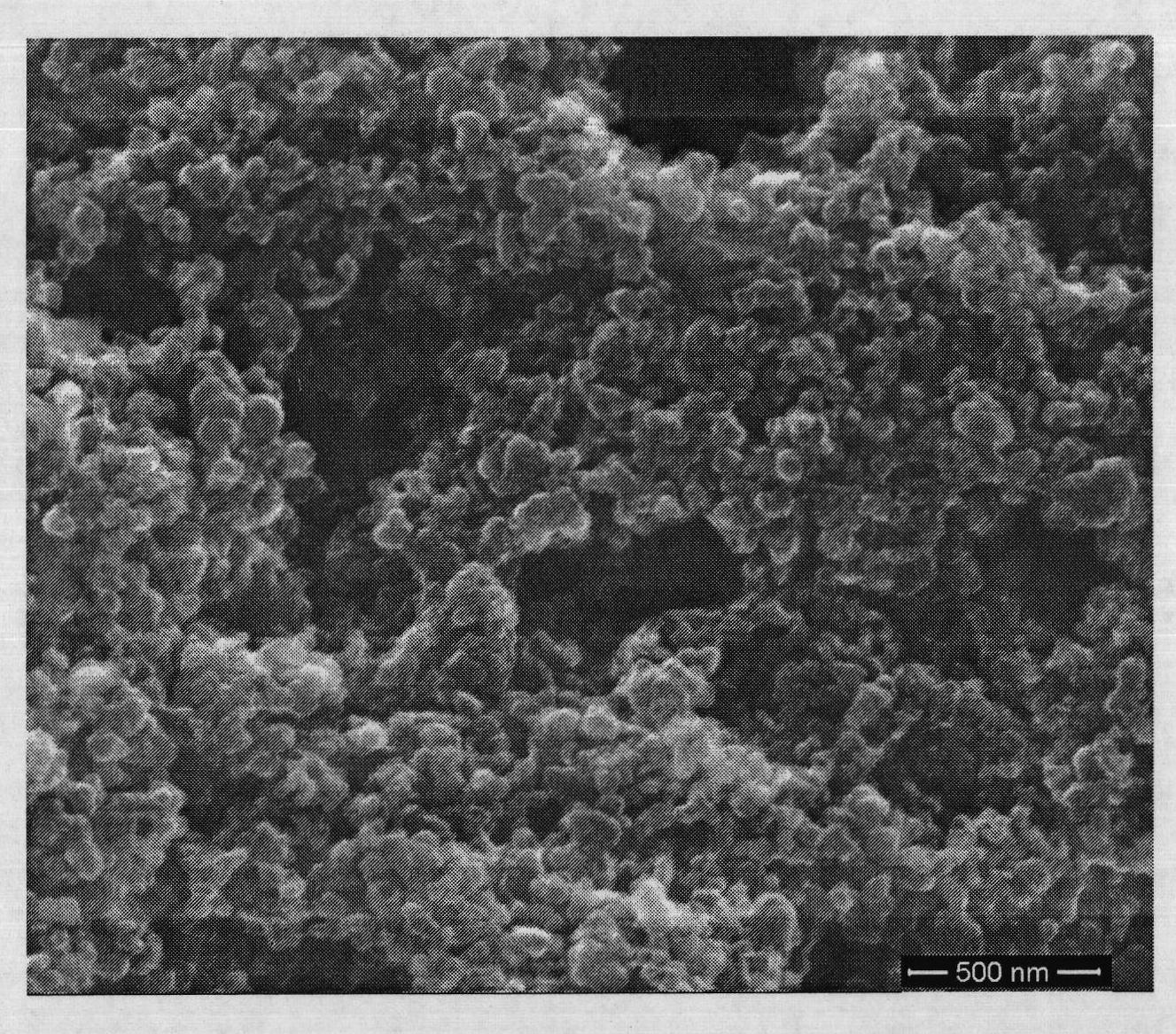

[0027] A carbon / aluminum composite cathode foil for solid aluminum electrolytic capacitors and a preparation method thereof: the mass ratio of conductive carbon black, potassium salt dispersant, epoxy resin and toluene is 1: (0.0001-0.001): (0.01-0.05): (10-50) For batching, firstly mix conductive carbon black, potassium salt dispersant and epoxy resin, then add toluene and stir to make a slurry.

[0028] The prepared slurry is evenly coated on the surface of the pretreated aluminum foil by dipping and pulling method, and the thickness of the carbon layer after drying is 20-30 μm. Then put the aluminum foil coated with the slurry into the vacuum furnace, at a vacuum of 10 -2 ~10 -1 The Pa and temperature are kept at 630-660° C. for 1-15 hours, and naturally cooled to room temperature in a vacuum furnace to prepare a carbon / aluminum composite cathode foil for a solid aluminum electrolytic capacitor.

[0029] The specific capacitance of the carbon / aluminum composite cathode fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com