Method for preparing Na4Fe3 (PO4) 2 (P2O7) by homogeneous phase method and application

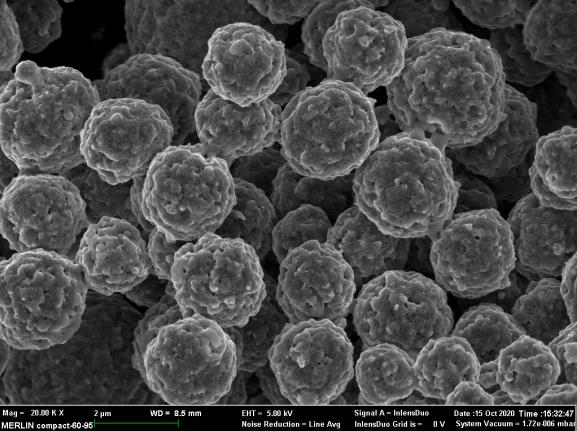

A homogeneous method and sand grinding technology, applied in chemical instruments and methods, inorganic chemistry, positive electrodes, etc., to achieve the effect of improving purity, wide distribution and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

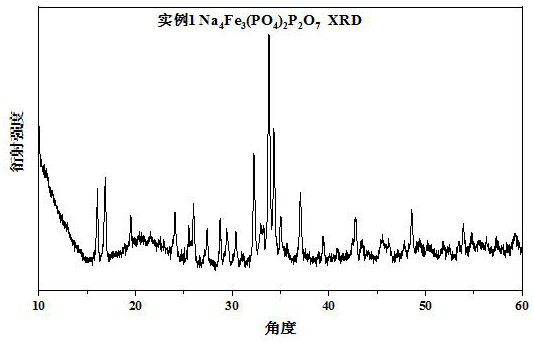

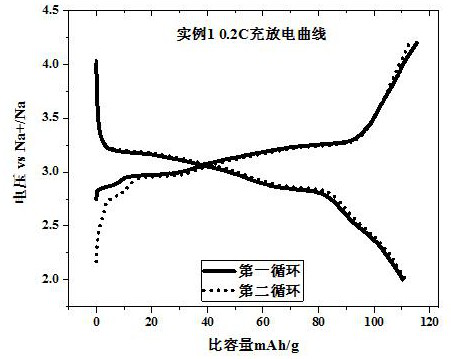

[0034] A positive electrode active material whose chemical formula is Na 4 Fe 3 (PO 4 ) 2 (P 2 o 7 ), the preparation method of the positive electrode active material is:

[0035] Sodium pyrophosphate Na 4 P 2 o 7 、FePO 4 、CH 3 COONa and citric acid are raw materials, and ethanol is a solvent. Among them, sodium pyrophosphate Na 4 P 2 o 7 Both sodium and phosphorus source, FePO 4 For iron source, sodium acetate CH 3 COONa is a supplementary sodium source, and citric acid is a carbon source;

[0036] 4.4605 g Na 4 P 2 o 7 10 hours 2 O, 9.06 g FePO4, 3.2808 g sodium acetate, and 8.4056 g citric acid monohydrate were added to 500 mL of 95% ethanol, ball milled at 20 rpm for 3 h, then sand milled at 2000 rpm for 3 h, and then 80% of the air inlet rate, 130 ° C Inlet air temperature, 0.5% feed rate feeding is spray-dried to obtain the precursor;

[0037] Then the precursor was placed in an argon atmosphere and calcined at 400 °C for 15 h to obtain Na 4 Fe 3 (...

Embodiment 2

[0040] A positive electrode active material whose chemical formula is Na 3 Fe 2 (PO 4 ) 2 (P 2 o 7 ), the preparation method of the positive electrode active material is:

[0041] as NaH 2 PO 4 , Fe 2 o 3 , Citric acid as raw material, acetone as solvent. Among them, NaH 2 PO 4 Both a source of sodium and phosphorus, Fe 2 o 3 as iron source, glucose as carbon source;

[0042] 18.7212 g NaH 2 PO 4 , 7.185g Fe 2 o 3 12.6084 g of glucose was dispersed in 400mL of 95% acetone, ball milled at 20rpm for 3h, then sand milled at 2000rpm for 3h, and then fed at 80% air inlet rate, 130°C inlet air temperature, and 0.5% feed rate. Spray drying to obtain the precursor;

[0043] Then the precursor was placed in a nitrogen atmosphere and calcined at 500 °C for 10 h to obtain Na 4 Fe 3 (PO 4 ) 2 (P 2 o 7 ). And assemble the button battery in a glove box with water and oxygen lower than 0.01ppm.

[0044] From Figure 4 It can be seen that the Na prepared in this ex...

Embodiment 3

[0046] A positive electrode active material whose chemical formula is Na 4 Fe 3 (PO 4 ) 2 (P 2 o 7 ), the preparation method of the positive electrode active material is:

[0047] Sodium pyrophosphate Na 4 P 2 o 7 、FePO 4 , sodium acetate CH 3 COONa and sucrose are used as raw materials, and ether is used as a solvent. Among them, sodium pyrophosphate Na 4 P 2 o 7 Both sodium and phosphorus source, FePO 4 For iron source, sodium acetate CH 3 COONa is a supplementary sodium source, and citric acid is a carbon source;

[0048] 8.921 g Na 4 P 2 o 7 10 hours 2 O, 18.12 g FePO4, 6.5616 g sodium acetate, and 16.8112 citric acid monohydrate were added to 500 mL of anhydrous diethyl ether, ball milled at 20 rpm for 3 hours, then sand milled at 2000 rpm for 3 hours, and then 80% of the air inlet rate, 130 ° C Air temperature, 0.5% feed rate feeding is spray-dried to obtain the precursor;

[0049] Then the precursor was placed in a mixed atmosphere of argon and hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com