Dropping nozzle device, device for recovering dropping undiluted solution, device for supplying dropping undiluted solution, device for solidifying surface of droplet, device for circulating aqueous a

一种氨水溶液、喷嘴装置的技术,应用在喷射装置、喷射装置、液体喷射装置等方向,能够解决硝酸双氧铀与铵离子反应不充分、差不良品、不易生成粒径ADU粒子等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

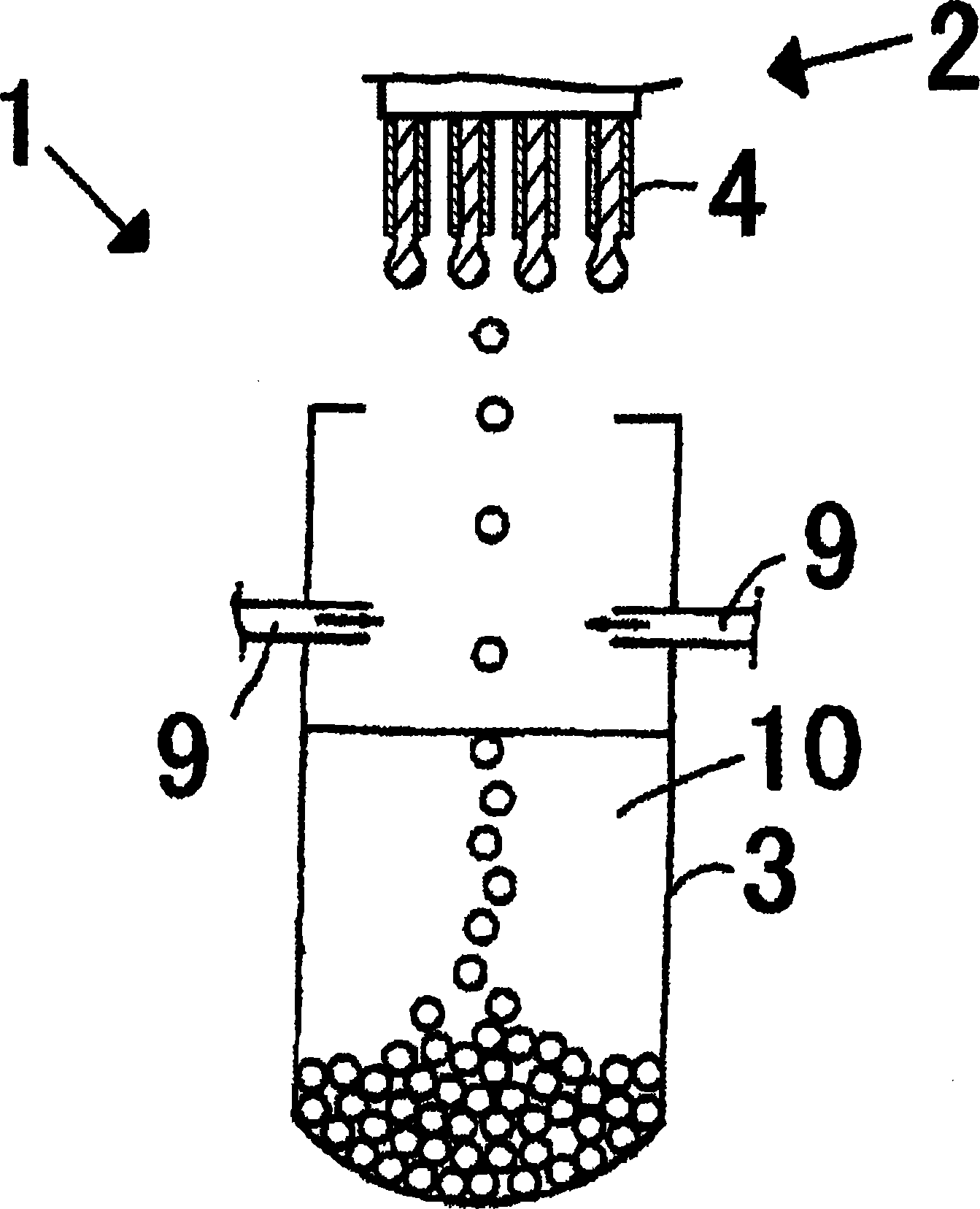

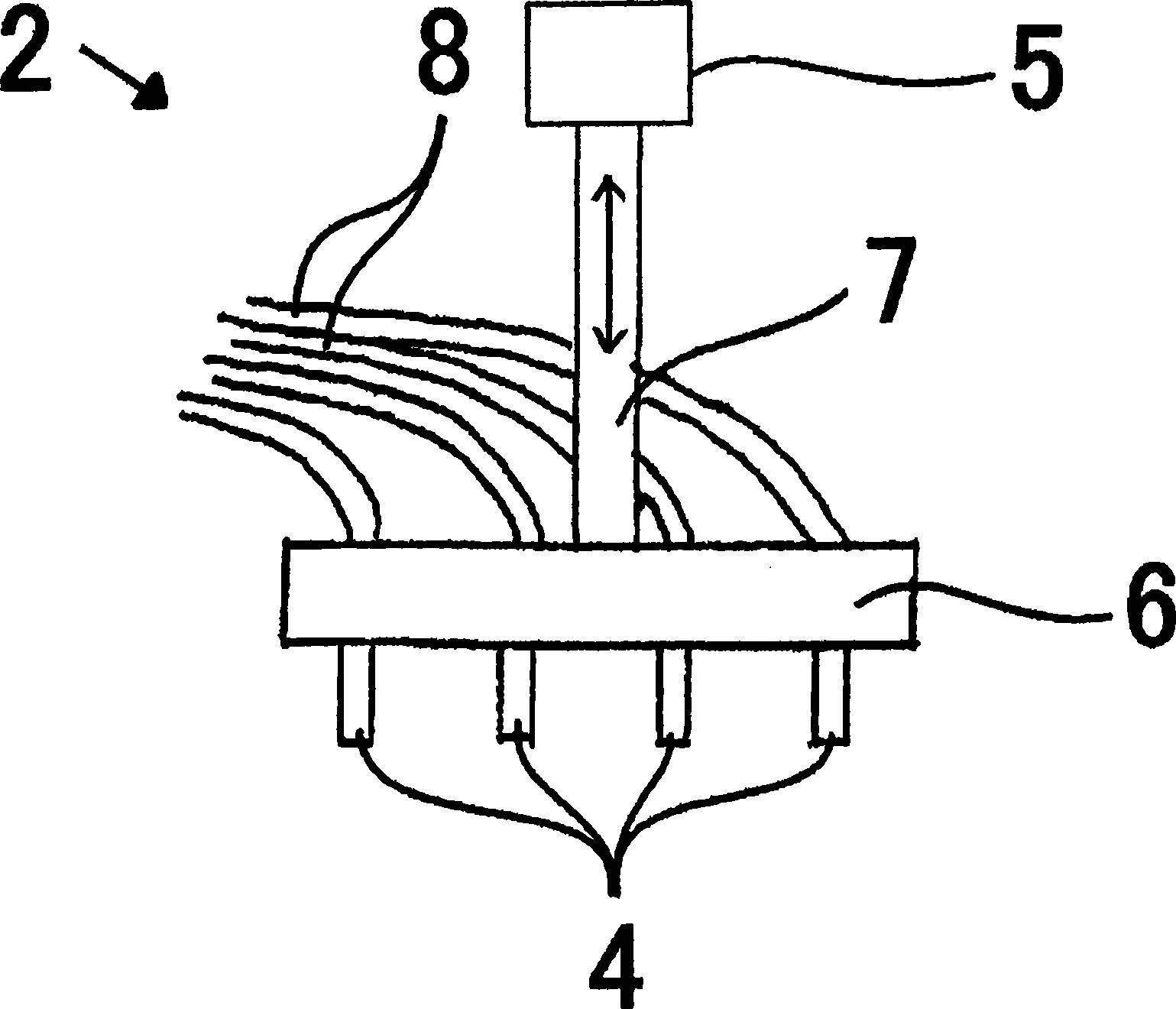

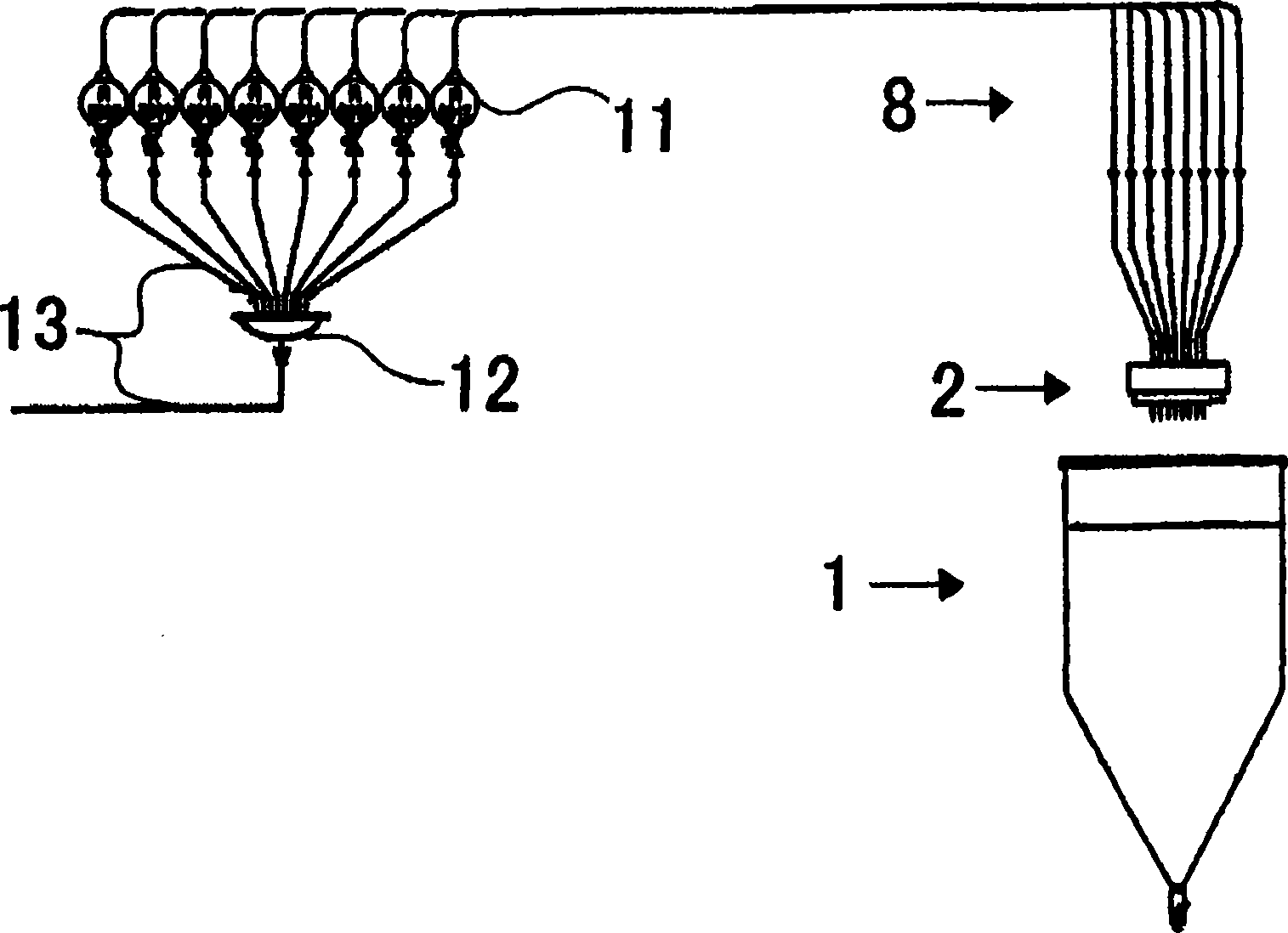

[0171] use Figure 5 and Figure 6 The drip nozzle assembly 2 is shown. The nozzle 4 is in the shape of a circular tube with an inner diameter of 0.5 mm and a length of 15 mm. Moreover, the drip stock solution storage tank 26 is a cylindrical member with an inner diameter of 6 mm and a length of 12 mm. Furthermore, the drop stock solution is obtained by adding and mixing polyvinyl alcohol resin or the like to a uranyl nitrate solution obtained by dissolving uranium oxide in nitric acid. The viscosity of the dropping stock solution is about 60 cP, and the concentration of the dropping stock solution containing uranyl nitrate is 0.7 mole-U / L.

[0172] The dripping stock solution stored in the dripping stock solution storage tank 26 is dripped from the front end opening of the nozzle 4 into the ammonia solution in the ammonia solution storage tank 3 . The ammonia concentration of the aqueous ammonia solution was 25% by volume.

[0173] ADU particles are formed by fully react...

Embodiment 2

[0192] A uranyl nitrate solution is mixed with a water-soluble cyclic ether such as tetrahydrofurfuryl alcohol (hereinafter referred to as THFA) to prepare a solution containing uranyl nitrate. On the other hand, a water-soluble polymer such as polyvinyl alcohol is mixed with water to form A water-soluble polymer solution with a concentration of 7.3% by mass is mixed with a water-soluble cyclic ether such as tetrahydrofurfuryl alcohol to prepare a water-soluble polymer solution, and then the solution containing the aforementioned uranyl nitrate is mixed with the aforementioned water-soluble polymer And prepare the dropping stock solution among the cost embodiment. THFA in the prepared dropping stock solution accounted for 45% by volume of the entire dropping stock solution, and the ratio of the aforementioned water-soluble polymer aqueous solution in the dropping stock solution accounted for 17% by volume of the entire dropping stock solution. The mixing ratio of the aforement...

Embodiment 3

[0218] Will U 3 o 8 5 kg of the powder was dissolved in 3.3 L of 60% by mass nitric acid to prepare a uranyl nitrate solution. To 7.5 L of uranyl nitrate solution, polyvinyl alcohol aqueous solution and tetrahydrofurfuryl alcohol were added as thickeners in proportions of 17 vol % and 45 vol % to the whole dropping stock solution, respectively, to prepare 24 L of dropping stock solution. After 120 minutes, the uranium concentration of the dripping stock solution was 180g / L, the temperature was 12°C, and the viscosity was 56×10 -3 Pa.s (56cP).

[0219] The dripping stock solution prepared as described above is stored in the dripping stock solution storage tank 25 of the ADU particle manufacturing apparatus 1 as the dripping stock solution 42 . This dripping stock solution 42 is sent to the dropping nozzle device 2 having the nozzle 4 through the dripping stock solution delivery path 43 via the stock solution supply pump 46 . Next, the dropping stock solution 42 was dropped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com