Method for preparing rare earth ion-doped yttrium aluminum garnet (Re: YAG) transparent laser ceramic by using hot-pressing post treatment

A technology of yttrium-aluminum garnet and laser ceramics, which is applied in the field of preparation of transparent laser ceramics doped with yttrium-aluminum garnet, can solve the problems of high preparation cost, difficult porosity, and high cost, and improve sintering efficiency, safety, and repeatability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

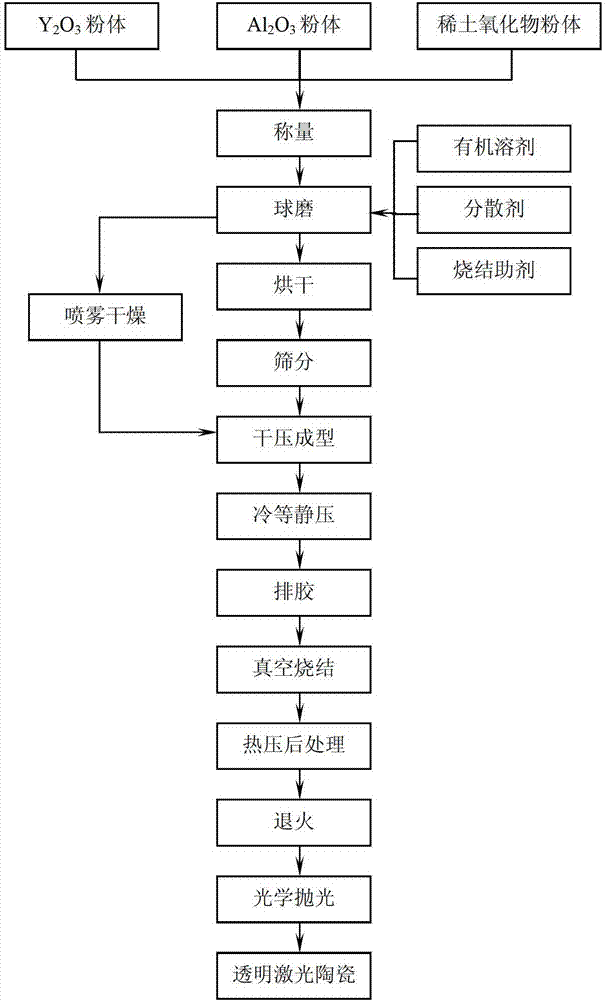

Method used

Image

Examples

Embodiment 1

[0066] Commercially available Y with a purity of 5N 2 o 3 、Nd 2 o 3 、Al 2 o 3 as raw material, according to the chemical formula (Y 0.98 Nd 0.02 ) 3 al 5 o 12 Prepare 40g of Nd:YAG ceramics with a Nd-doped concentration of 2.0at%, and calculate the mass of each oxide raw material as Y 2 o 3 :22.2429g, Nd 2 o 3 :0.6764g, Al 2 o 3 : 17.0807g, each oxide was weighed in turn with a precision electronic analytical balance (accuracy 0.0001g), and then put into an alumina ball mill jar, 80g of absolute ethanol was added, and 200g of alumina balls with a diameter of Φ6mm were used as the ball milling medium, and 0.32g (equivalent to 0.8% of the total weight of the oxide powder) TEOS is used as a sintering aid, and 0.4g of polyacrylic acid (equivalent to 1.0% of the total weight of the oxide powder) is used as a dispersant.

[0067] After ball milling and mixing for 12 hours at a speed of 500 rpm. The ball-milled mixed slurry was taken out and spray-dried with an inlet ...

Embodiment 2

[0071] Commercially available Y with a purity of 4N 2 o 3 、Nd 2 o 3 、Al 2 o 3 , CeO 2 For ceramics, according to the chemical formula (Y 0.989 Nd 0.01 Ce 0.001 ) 3 al 5 o 12 Prepare 40g of Nd:Ce:YAG powder with a Nd-doped concentration of 1.0at% and a Ce-doped ion concentration of 0.1at%, and calculate the mass of each oxide raw material as Y 2 o 3 :22.5040g, Nd 2o 3 :0.3391g, CeO 2 :0.0.347g, Al 2 o 3 : 17.1239g, each oxide was weighed in turn with a precision electronic analytical balance (accuracy 0.0001g), and then put into a nylon ball mill jar, 160g of absolute ethanol was added, 200g of alumina balls with a diameter of Φ5mm were used as the ball milling medium, and 0.32 g (equivalent to 0.8% of the total weight of oxide powder) TEOS as a sintering aid, 0.4g oleic acid (equivalent to 1.0% of the total weight of oxide powder) and 0.8g polyethylene glycol (PEG400, equivalent to oxide powder 2.0% of the total body weight) as a dispersant.

[0072] After b...

Embodiment 3

[0076] Commercially available Y with a purity of 4N 2 o 3 、Nd 2 o 3 、Al 2 o 3 as raw material, according to the chemical formula (Y 0.96 Nd 0.04 ) 3 al 5 o 12 Prepare 40g of Nd:YAG ceramic powder with a Nd-doped concentration of 4.0at%, and calculate the mass of each oxide raw material as Y 2 o 3 :21.6684g, Nd 2 o 3 : 1.3453g, Al 2 o 3 : 16.9862g, weigh each oxide in turn with a precision electronic analytical balance (accuracy 0.0001g), then put it into an agate ball mill jar, add 40g of absolute ethanol, 200g of agate balls with a diameter of Φ6mm as a ball milling medium, and add 0.2g (equivalent to 0.5% of the total weight of oxide powder) TEOS and 0.04gMgO (equivalent to 0.1% of the total weight of oxide powder) as sintering aids, 0.4g polyammonium methacrylate (equivalent to 1.0% of the total weight of oxide powder) %) as a dispersant.

[0077] After ball milling and mixing for 20 hours at a speed of 400 rpm. The ball-milled mixed slurry was taken out an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com