Method for preparing yttrium aluminum garnet based transparent ceramic by slip casting

A technology of yttrium aluminum garnet and grouting molding, which is applied in the field of preparing yttrium aluminum garnet-based transparent ceramics by grouting molding, can solve the problems of difficult realization, large size, complex shape and composite structure, and achieves a widening of preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

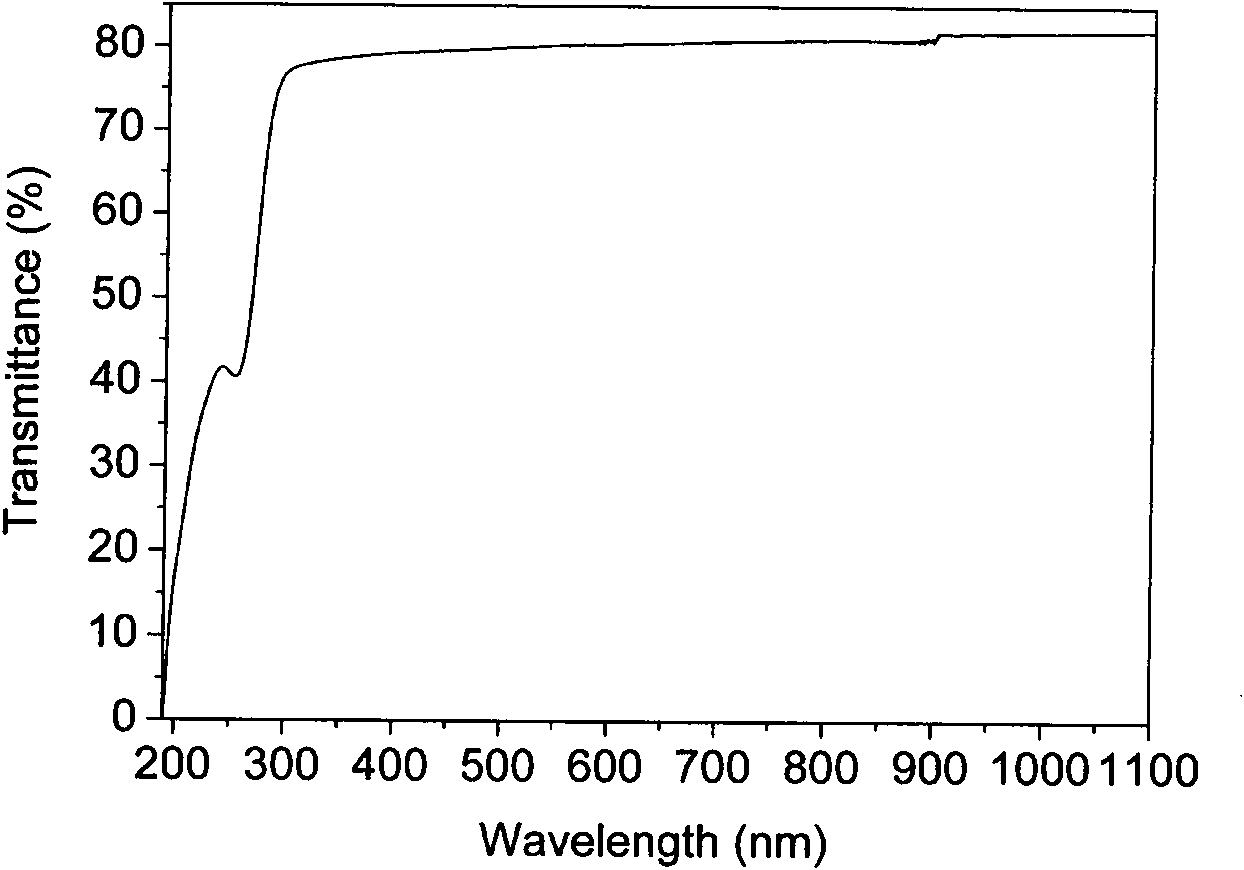

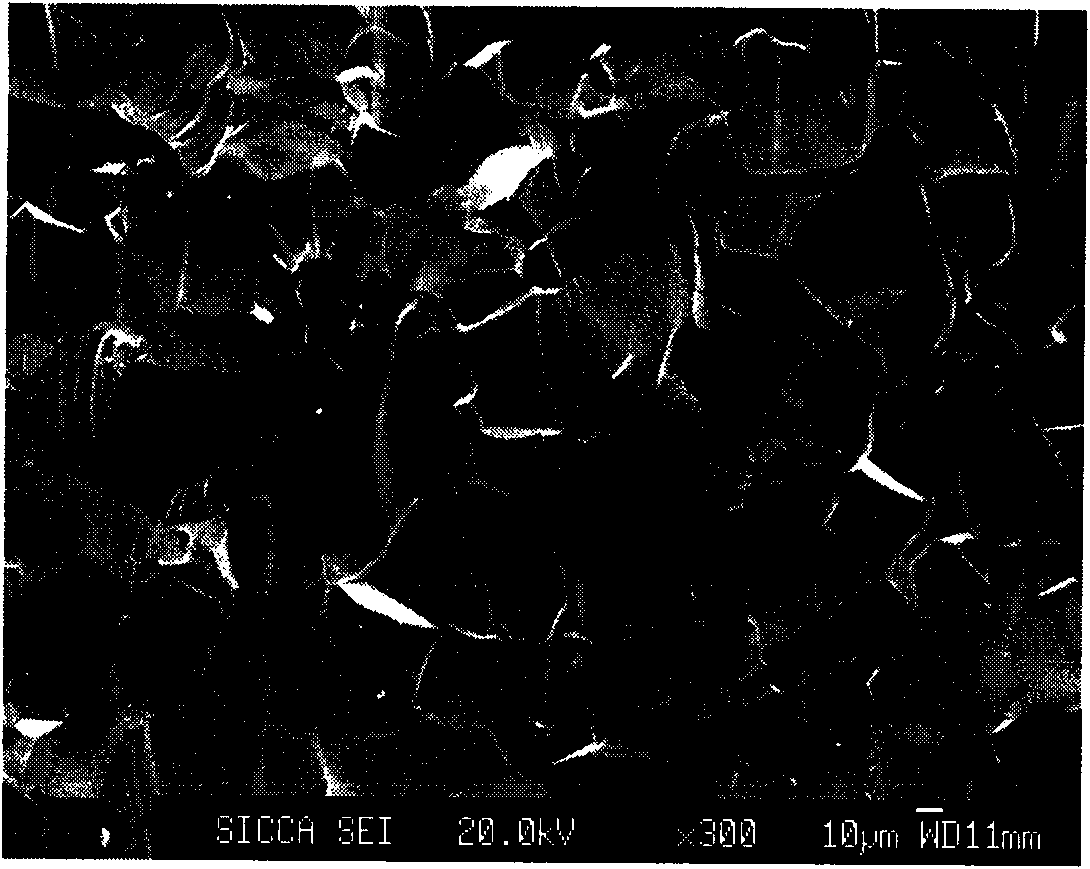

Embodiment 1

[0034] 25.4904g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.8715g Y with an average particle size of 3μm 2 o 3 Powder, 0.3562g tetraethyl orthosilicate (TEOS) and 0.0594g herring oil (MFO) are put into high-purity alumina ball mill jar, add 200g high-purity alumina balls, 34ml absolute ethanol, and then ball mill and mix for 8 hours After adding 0.1188g of polyvinyl butyral (PVB), 0.1782g of polyethylene glycol (PEG) and 0.1484g of polyether-modified silicone, ball milling was continued for 2 hours to obtain a ceramic slurry for slip casting. Slurry molding was performed on the prepared slurry. After the grouting, the green body was dried at 30° C. for 24 hours, then at 70° C. for 12 hours, and peeled off from the mold to obtain a ceramic green body with a thickness of about 4 mm. The prepared ceramic green body is pre-fired in a muffle furnace: the heating rate is 5°C / min, the pre-fire temperature is 600°C, and the holding time is 4h, so as to eliminate...

Embodiment 2

[0036] 25.4904g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.1955g Y with an average particle size of 3μm 2 o 3 Powder, 0.5047g of Nd with an average particle size of 250nm 2 o 3 Powder, 0.3582g tetraethyl orthosilicate (TEOS) and 0.0895g herring oil (MFO) are put into a high-purity alumina ball mill jar, add 200g high-purity alumina balls, 36ml absolute ethanol, and then ball mill and mix for 10 hours After adding 0.2985g polyvinyl butyral (PVB), 0.1194g butyl benzyl phthalate (BBP) and 0.0597g polyether-modified silicone, ball milling was continued for 2 hours to obtain a ceramic slurry for slip casting. Slurry molding was performed on the prepared slurry, and the green body after grouting was dried at 25° C. for 24 hours, then dried at 80° C. for 10 hours, and peeled off from the mold to obtain a ceramic green body with a thickness of about 4 mm. The prepared ceramic green body was pre-fired in a muffle furnace: the heating rate was 2.5 °C / min, the...

Embodiment 3

[0038] 25.4903g of α-Al with an average particle size of 300nm 2 o 3 Powder, 33.5328g Y with an average particle size of 3μm 2 o 3 Powder, 0.5047g Er with an average particle size of 7μm 2 o 3 Powder, 0.4800g tetraethyl orthosilicate (TEOS) and 0.1188g polyacrylic acid (PAA) are put into high-purity alumina ball mill jar, add high-purity alumina ball 180g, absolute ethanol 30ml, after ball milling and mixing for 10h, After adding 0.0594g of polyvinyl butyral (PVB), 0.0594g of butyl benzyl phthalate (BBP) and 0.0297g of polyether-modified silicone, ball milling was continued for 2 hours to obtain a ceramic slurry for slip casting. Slurry molding was performed on the prepared slurry, and the green body after the slurry injection was dried at 25° C. for 24 hours, and peeled off from the mold to obtain a ceramic green body with a thickness of about 3 mm. The prepared ceramic green body was pre-fired in a muffle furnace: the heating rate was 2.5°C / min, the pre-fire temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com