Method for preparing rare earth-doped yttrium aluminum garnet transparent ceramic

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of preparation of rare earth doped yttrium aluminum garnet transparent ceramics, can solve the problems of serious powder agglomeration, unfavorable molding, poor powder fluidity, etc., and achieve good mechanical properties, straight line The effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

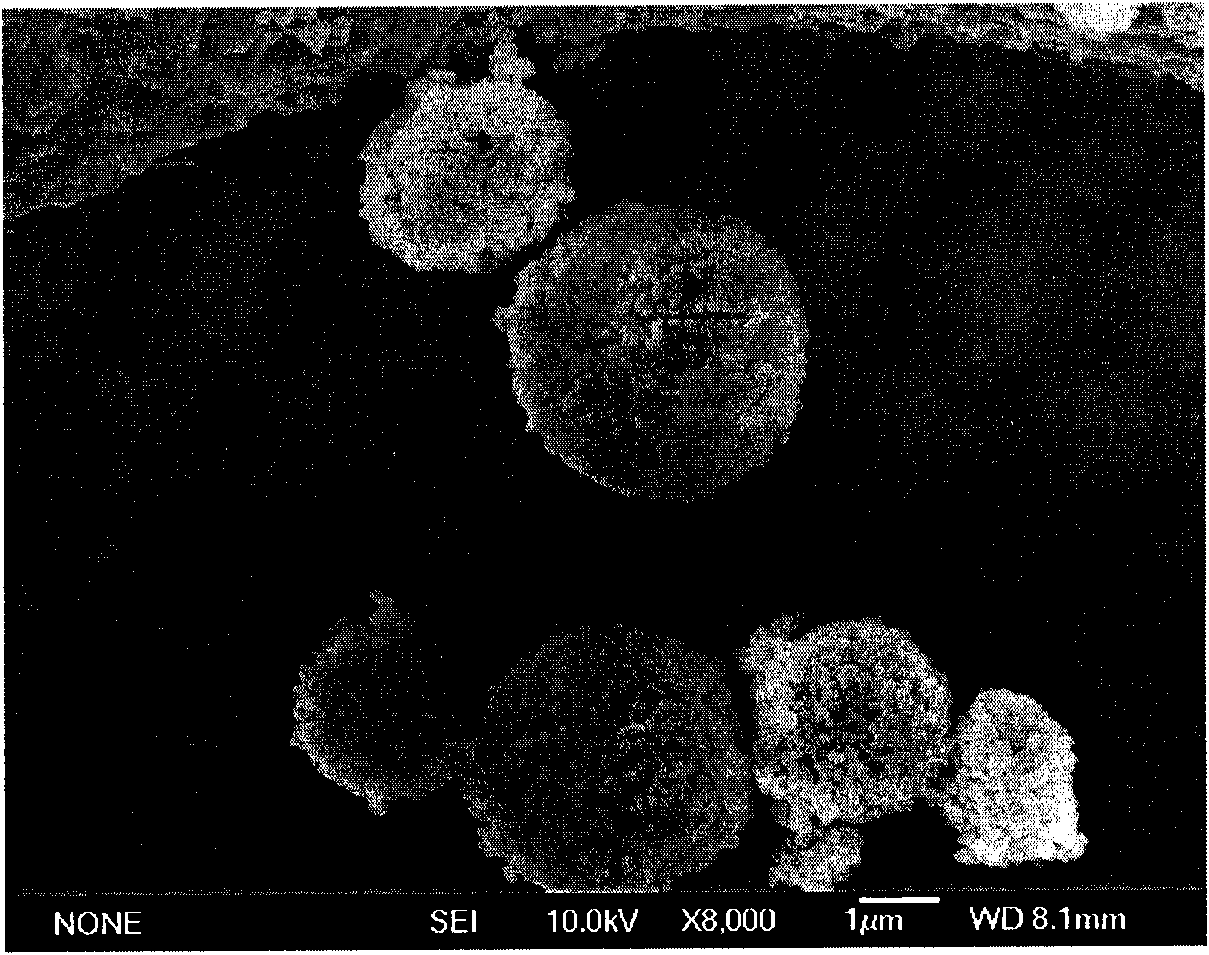

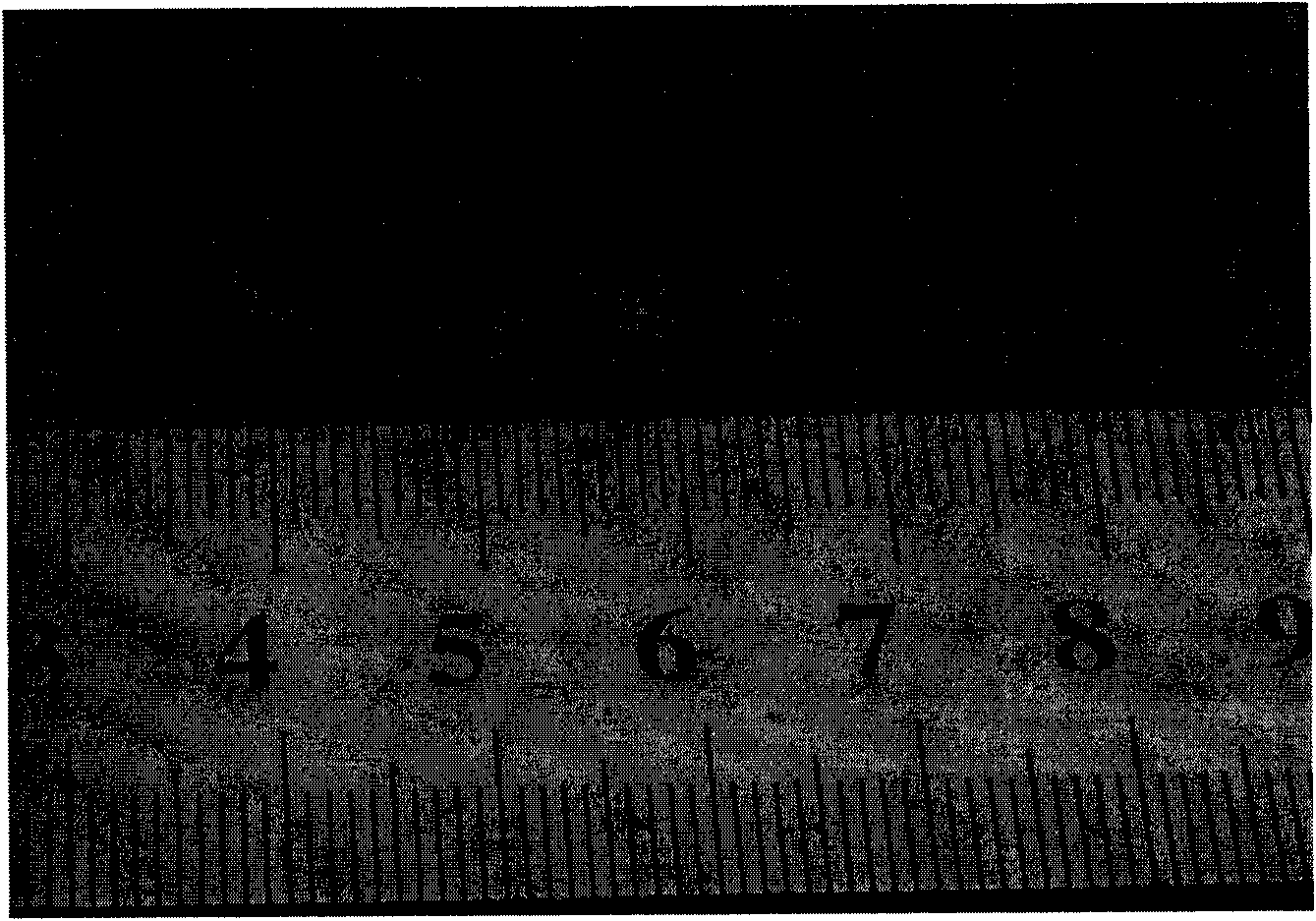

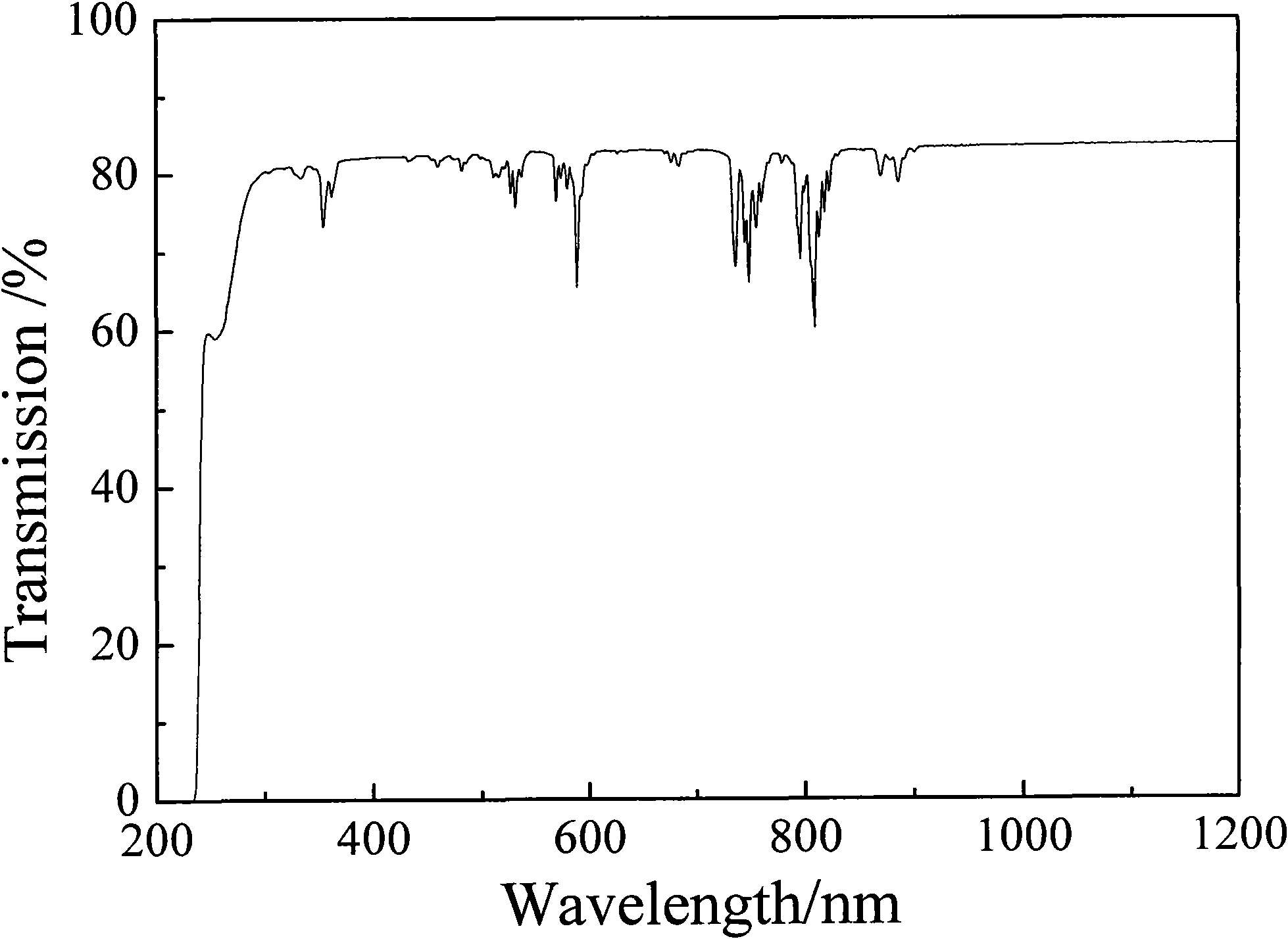

[0027] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS and 0.3600g of PVB into a high-purity agate ball mill jar, add 72g of high-purity agate balls, anhydrous Ethanol 6g, then ball milled for 20h. After ball milling, the slurry was spray-dried, the inlet temperature was 110° C., the spray gas flow rate was 400 Nor mlitre / h, and the feed rate was 6 ml / min. Axial one-way pressurization with a pressure of 10Mpa, pressed into a disc of Φ15, and then cold isostatic pressing under a pressure of 200Mpa. The degreased green body was sintered in a vacuum furnace, the heating rate of the furnace was 10°C / min, the final sintering temperature was 1835°C, and the sintering time was 15h. Finally, the ceramics were ground and polished to a thickness of 1.50 mm with a surface grinder and diamond paste. The photo of the polished 1at%Nd:YAG ceramic 1.50mm piece is shown in figure 2 , and its transmittance curve is shown in image 3 . At the laser w...

Embodiment 2

[0029] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS, 0.3600g of PVB and 0.0060g of castor oil into a high-purity agate ball mill jar, other processes and implementation Example 1 is the same. The degreased green body was sintered in a vacuum furnace with a heating rate of 10°C / min, pre-sintering at 1500°C for 5 hours, final sintering temperature of 1820°C, and sintering time of 10 hours. Finally, the ceramics were ground and polished to 1.00 mm thickness with a surface grinder and diamond paste. The linear transmittance of the sample at the laser wavelength (1064nm) is 83%.

Embodiment 3

[0031] Put 5.098g of α-Al2O3 powder, 6.7066g of Y2O3 powder, 0.1010g of Nd2O3, 0.0600g of TEOS, 0.3000g of PVB and 0.0060g of castor oil into a high-purity agate ball mill jar, other processes and implementation Example 1 is the same. The degreased green body was sintered in a vacuum furnace. The heating rate of the furnace was 10°C / min, the final sintering temperature was 1830°C, and the sintering time was 40h. Finally, the ceramics were ground and polished to a thickness of 3.00 mm with a surface grinder and diamond paste. The linear transmittance of the sample at the laser wavelength (1064nm) is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com