Preparation method of fluorescent transparent ceramic with high optical performance

A technology of transparent ceramics and optical properties, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high price, unsustainable supply, and restrictions, and achieve the effect of excellent appearance and excellent optical quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

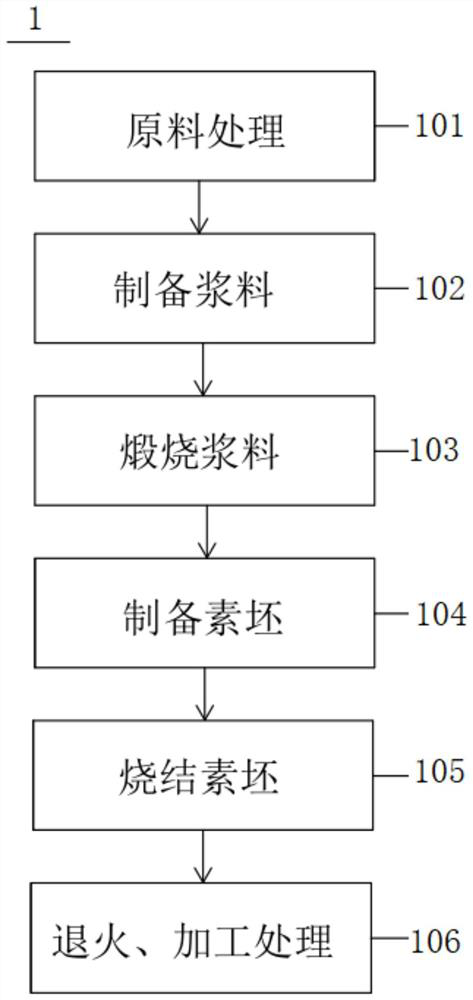

[0021] see figure 1 , which is a schematic flow chart of the steps of a method for preparing a cerium-doped yttrium aluminum garnet transparent ceramic according to an embodiment of the present application. As shown in the figure, the preparation method 1 of the cerium-doped yttrium aluminum garnet transparent ceramic in this embodiment is to prepare a fluorescent transparent ceramic doped with 0.1 at% Ce. The preparation method 1 of fluorescent transparent ceramics with high optical performance includes the following steps 101 to 106, wherein:

[0022] Step 101, raw material processing. The metal oxide powders of yttrium oxide, aluminum oxide and cerium oxide are calcined to remove organic matter and moisture. Specifically, the yttrium oxide, aluminum oxide and cerium oxide powders are calcined in a muffle furnace for use.

[0023] Step 102, preparing slurry. The calcined metal oxide powder, calcium carbonate powder and tetraethoxysilane are put into a ball milling tank, ...

Embodiment 2

[0031] see figure 1 , which is a schematic flow chart of the steps of a method for preparing a cerium-doped yttrium aluminum garnet transparent ceramic according to an embodiment of the present application. As shown in the figure, the preparation method 1 of the cerium-doped yttrium aluminum garnet transparent ceramic in this embodiment is to prepare a fluorescent transparent ceramic doped with 0.1 at% Ce. The preparation method 1 of fluorescent transparent ceramics with high optical performance includes the following steps 101 to 106, wherein:

[0032] Step 101, raw material processing. The metal oxide powders of yttrium oxide, aluminum oxide and cerium oxide are calcined to remove organic matter and moisture. Specifically, the yttrium oxide, aluminum oxide and cerium oxide powders are calcined in a muffle furnace for use.

[0033] Step 102, preparing slurry. The calcined metal oxide powder, calcium carbonate powder and tetraethoxysilane are put into a ball milling tank, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com