Method for preparing yttrium aluminum garnet-based transparent ceramic through aqueous tape casting

A technology of water-based tape casting and yttrium aluminum garnet, which is applied in the direction of ceramic layered products, chemical instruments and methods, layered products, etc., can solve the problems of increasing the density of ceramic green bodies, and achieve low cost and environmental compatibility The effect of good sex and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of ceramic slurry

[0027] First follow Y 3 al 5 o 12 The stoichiometric ratio of weighing commercial Al 2 o 3 Powder and Y 2 o 3 powder as raw material. Use water, preferably deionized water as solvent, polyacrylic acid or polymethacrylic acid or triethanolamine as dispersant, and prepare Al by ball milling process 2 o 3 Powder and Y 2 o 3 Slurry of powder mixture. The solid content of the slurry can be 20 vol% to 53 vol%, the amount of the dispersant can be 0.01 to 3.0 wt%, and the ball milling time can be 8 to 24 hours.

[0028]Then polyvinyl alcohol is used as a binder, polyethylene glycol or glycerol is used as a plasticizer, and a ball milling process is used to prepare casting slurry. The amount of polyvinyl alcohol can be 5 wt% to 20 wt%, the amount of polyethylene glycol or glycerin can be 5 wt% to 30 wt%, and the ball milling time is 8 to 24 hours.

[0029] Cast film preparation

[0030] The casting slurry above can be scraped into a ...

Embodiment 1

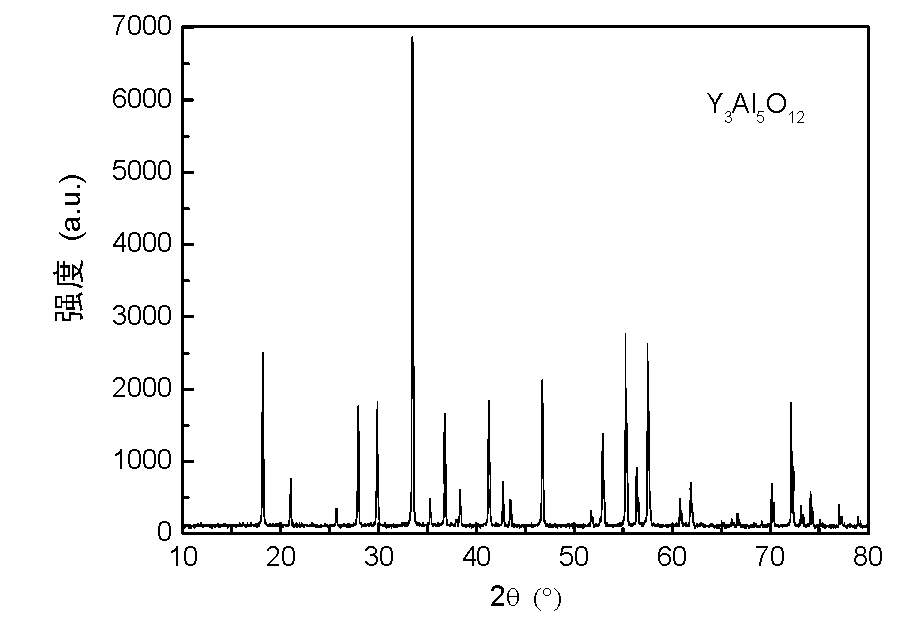

[0043] Follow Y 3 al 5 o 12 The stoichiometric ratio weighs high-purity commodity Al 2 o 3 Powder 42.4838 g, Y 2 o 3 56.4525 g of powder was added with 21.744 g of deionized water and 0.8 wt% polyacrylic acid as a dispersant, and ball milled and mixed to prepare a slurry, which was ball milled for 24 hours. Then add 10 wt% polyvinyl alcohol as a binder, 15 wt% polyethylene glycol as a plasticizer, continue ball milling and mixing, and prepare casting slurry, and the ball milling time is 24 hours. The homogeneously mixed slurry is moved into the vacuum degassing system and undergoes vacuum treatment to eliminate the air bubbles in the slurry. The degassed slurry was poured into the slurry storage tank on the tape casting machine, the distance between the blades was adjusted to 400 μm, and the cast film was scraped at a rate of 1 cm / s. The cast film was dried at a temperature of 40 °C for 24 hours, and the dried cast film was as follows: figure 1 shown. The dried cast f...

Embodiment 2

[0045] Follow Y 3 al 5 o 12 The stoichiometric ratio weighs high-purity commodity Al 2 o 3 Powder 42.4838 g, Y 2 o 3 56.4525 g of powder was added with 26.576 g of deionized water and 0.7 wt% polymethacrylic acid as a dispersant, and ball milled and mixed to prepare a slurry. The ball milled for 12 hours. Then add 12 wt% polyvinyl alcohol as a binder, 15 wt% glycerol as a plasticizer, continue ball milling and mixing, and prepare casting slurry, and the ball milling time is 12 hours. The homogeneously mixed slurry is moved into the vacuum degassing system and undergoes vacuum treatment to eliminate the air bubbles in the slurry. The degassed slurry was poured into the slurry storage tank on the tape casting machine, the distance between the blades was adjusted to 500 μm, and the cast film was scraped at a rate of 1 cm / s. The cast film was dried at a temperature of 35°C for 24 hours. The dried cast film was cut into 20 mm × 20 mm film, and 40 layers were taken and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com