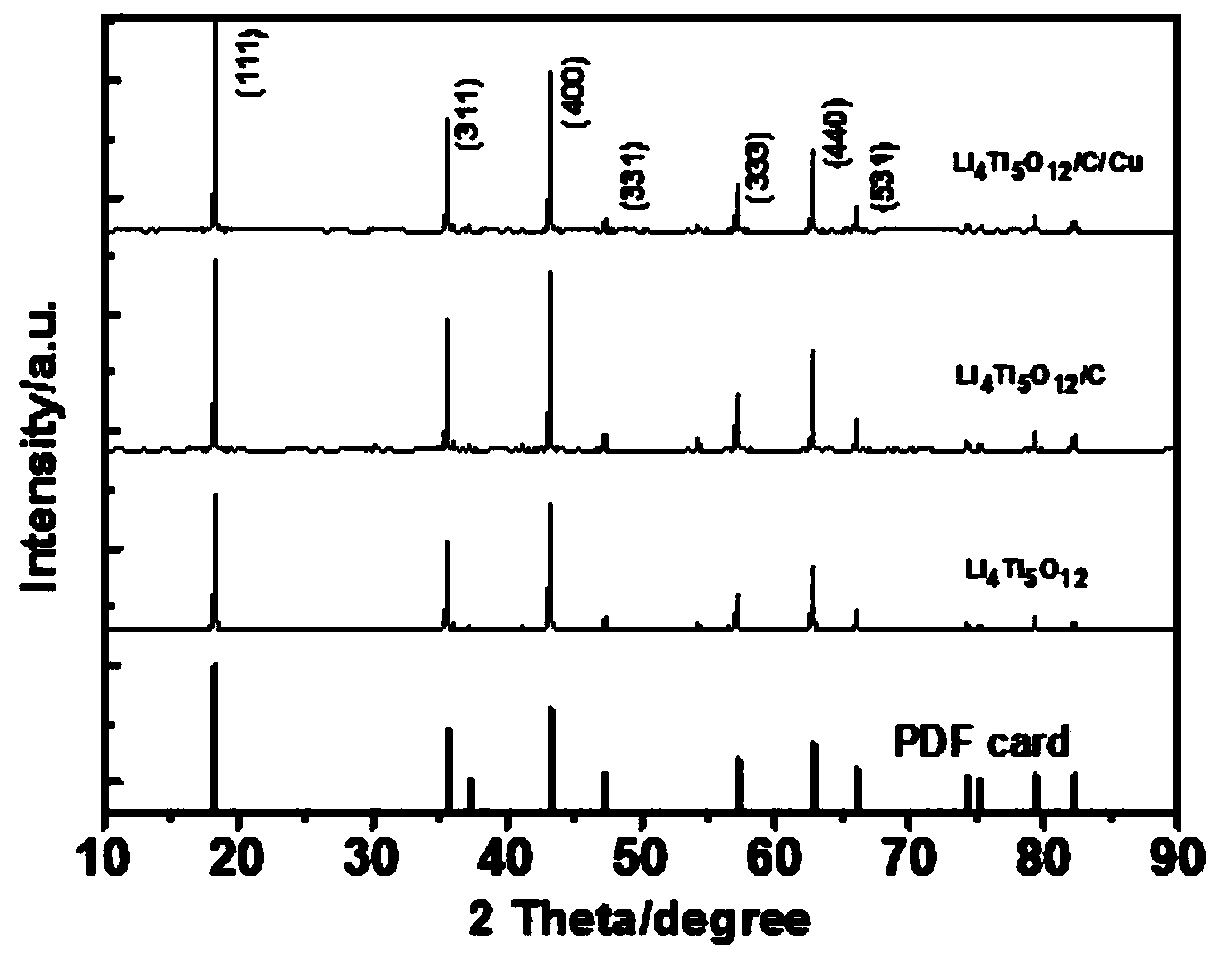

Lithium titanate composite negative electrode material for lithium battery and preparation method of lithium titanate composite negative electrode material

A negative electrode material, lithium titanate technology, used in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as poor conductivity, and achieve the effects of improving electronic conductivity, reducing polarization, and reducing charge transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides the following technical solutions: a lithium titanate composite negative electrode material for lithium batteries, the raw materials of which are as follows in terms of mass parts: CMC: 0.003g, PEG400: 0.1156g, SBR: 0.006g, lithium acetate: 0.726g, nano-TiO 2 : 1g, sucrose: 0.1646g, copper sulfate: 0.2246g, the CMC is sodium carboxymethylcellulose, the PEG400 is polyethylene glycol 400 humectant solubilizer, the SBR is styrene-butadiene rubber, the acetic acid The concentration of lithium is greater than 5%, the weight percentage of the sucrose is 5 wt%, and the weight percentage of the copper sulfate is 5 wt%.

[0040] The present invention also provides a preparation method of a lithium titanate composite negative electrode material for a lithium battery, comprising the following steps:

[0041] S1: Dissolve CMC, PEG400 and SBR in 30ml deionized water respectively, and stir in an agate jar until the solution is uniform and clear;

[0042] S2: W...

Embodiment 2

[0050] The invention provides the following technical solutions: a lithium titanate composite negative electrode material for lithium batteries, the raw materials of which are as follows in terms of mass parts: CMC: 0.003g, PEG400: 0.1156g, SBR: 0.006g, lithium acetate: 0.726g, nano-TiO 2 : 1g, sucrose: 0.115g, the CMC is sodium carboxymethylcellulose, the PEG400 is a polyethylene glycol 400 humectant solubilizer, the SBR is styrene-butadiene rubber, and the concentration of lithium acetate is greater than 5%. , the weight percent of the sucrose is 5wt%.

[0051] The present invention also provides a preparation method of a lithium titanate composite negative electrode material for a lithium battery, comprising the following steps:

[0052] S1: Dissolve CMC, PEG400 and SBR in 30ml deionized water respectively, and stir in an agate jar until the solution is uniform and clear;

[0053] S2: Weigh lithium acetate and nano-TiO respectively 2 and sucrose are dissolved in the solut...

Embodiment 3

[0061] The invention provides the following technical solutions: a lithium titanate composite negative electrode material for lithium batteries, the raw materials of which are as follows in terms of mass parts: CMC: 0.003g, PEG400: 0.1156g, SBR: 0.006g, lithium acetate: 0.726g, nano-TiO 2 : 1g, the CMC is sodium carboxymethyl cellulose, the PEG400 is a polyethylene glycol 400 humectant solubilizer, the SBR is styrene-butadiene rubber, and the concentration of the lithium acetate is greater than 5%.

[0062] The present invention also provides a preparation method of a lithium titanate composite negative electrode material for a lithium battery, comprising the following steps:

[0063] S1: Dissolve CMC, PEG400 and SBR in 30ml deionized water respectively, and stir in an agate jar until the solution is uniform and clear;

[0064] S2: Weigh lithium acetate and nano-TiO respectively 2 Dissolve in the solution in step S1, and then ball mill in a ball mill for 2 hours to obtain a u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com