Preparation method of high-efficiency compound antibacterial separation membrane

A composite antibacterial and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, can solve the problems of cumbersome preparation methods, decreased antibacterial properties, easy to be eluted, etc., and achieves novel preparation methods. The effect of preventing leakage and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

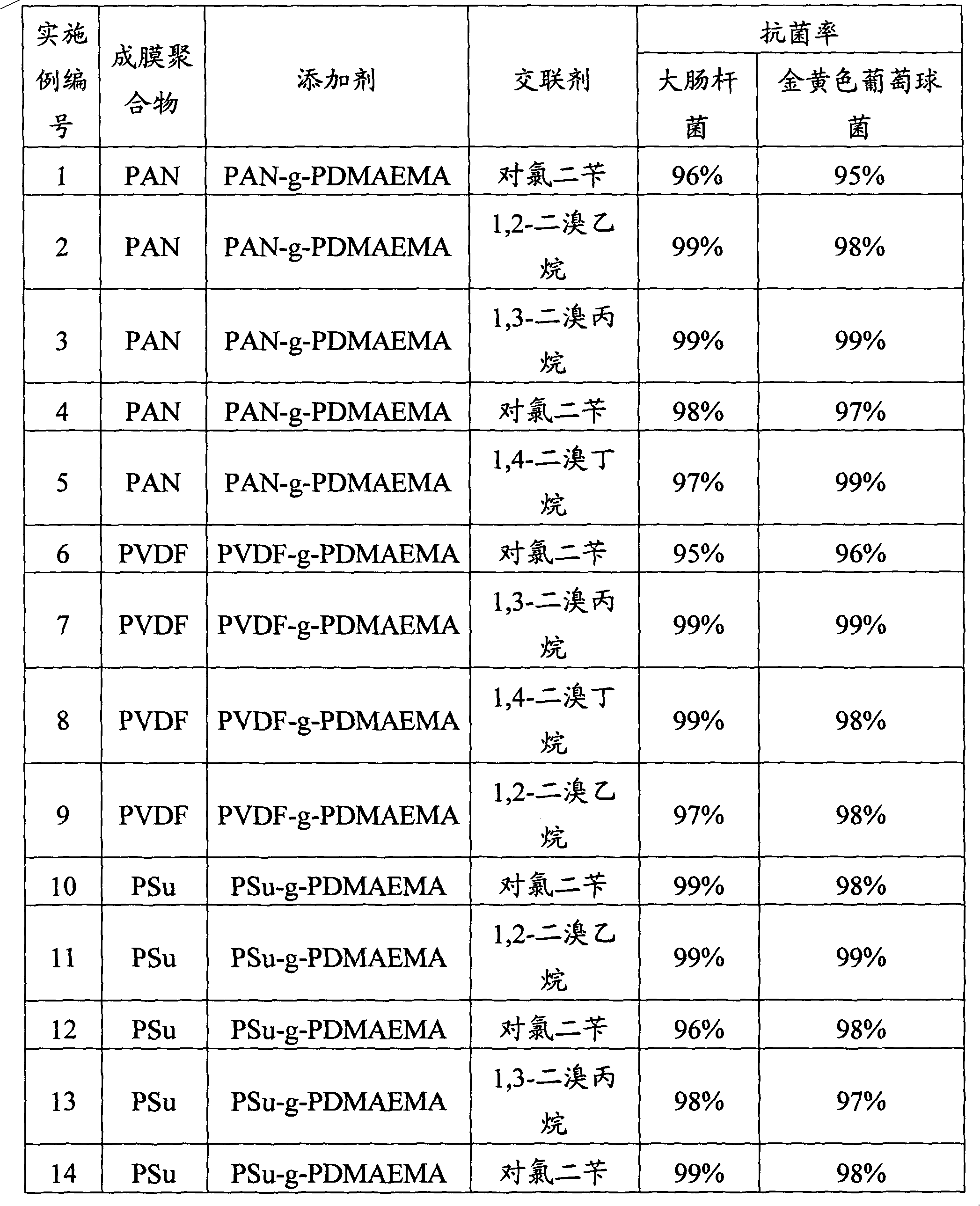

Examples

Embodiment 1

[0026] 7.5g polyacrylonitrile (number average molecular weight is 5kg / mol), 7.5g additive (PAN-g-PDMAEMA, wherein the molar content of PDMAEMA is 5%) is dissolved in DMF, under 50 ℃, constantly stirs to prepare the weight percent A homogeneous solution with a concentration of 30%, remove the air bubbles after standing for several hours, use the solution as a casting solution, scrape it on a glass plate, take it out after immersing in water for 30 minutes, and then use the immersion precipitation phase inversion method to prepare polypropylene Nitrile separation membrane.

[0027] The above-mentioned polyacrylonitrile separation membrane was immersed in water at room temperature for 1 hour, and then placed in water at 90° C. for annealing treatment for 1 hour to obtain an annealed polyacrylonitrile separation membrane.

[0028] Put the above annealed polyacrylonitrile separation membrane into 0.005mol / L silver nitrate aqueous solution and soak for 12 hours, then take it out qui...

Embodiment 2

[0031] 6.25g polyacrylonitrile (Mn is 150kg / mol), 1.25g additive (PAN-g-PDMAEMA, wherein the molar content of PDMAEMA is 50%) is dissolved in NMP, under 50 ℃, constantly stirring is formulated into the weight percent concentration of 15% homogeneous solution, remove air bubbles after standing for several hours, use this solution as casting solution, scrape it on a glass plate, take it out after immersing in water for 30 minutes, that is, prepare polyacrylonitrile separation by immersion precipitation phase inversion method membrane.

[0032] The above polyacrylonitrile separation membrane was put into a 20°C deionized water bath, soaked for 12 hours, and then the water bath was heated to 90°C for annealing treatment for 6 hours to obtain an annealed polyacrylonitrile separation membrane.

[0033] Put the above-mentioned annealed polyacrylonitrile separation membrane into 0.01mol / L silver nitrate aqueous solution and soak for 6 hours, then take it out quickly and put it into 0....

Embodiment 3

[0036] Dissolve 0.25g polyacrylonitrile (Mn is 1000kg / mol), 0.25g additive (PAN-g-PDMAEMA, wherein PDMAEMA molar content is 50%) in DMSO, stir constantly at 50 ℃ and prepare the weight percent concentration of 5% homogeneous solution, remove air bubbles after standing for several hours, use this solution as casting solution, scrape it on a glass plate, take it out after immersing in water for 30 minutes, that is, prepare polyacrylonitrile separation by immersion precipitation phase inversion method membrane.

[0037] The above polyacrylonitrile separation membrane was placed in a deionized water bath at 15°C, soaked for 24 hours, and then the water bath was heated to 90°C for annealing treatment for 12 hours to obtain an annealed polyacrylonitrile separation membrane.

[0038] Put the annealed polyacrylonitrile separation membrane into 0.02mol / L silver nitrate aqueous solution and soak for 0.5 hours, then take it out quickly and put it into 0.4mol / L NaBH 4 After soaking in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com