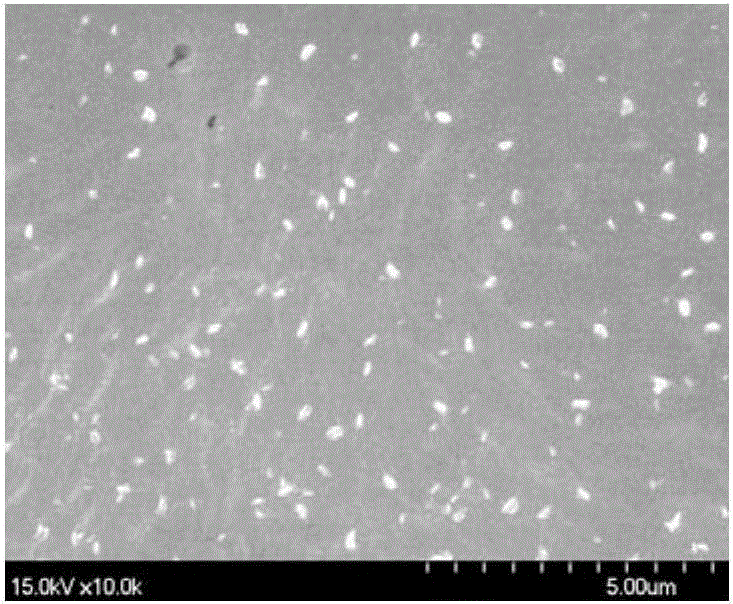

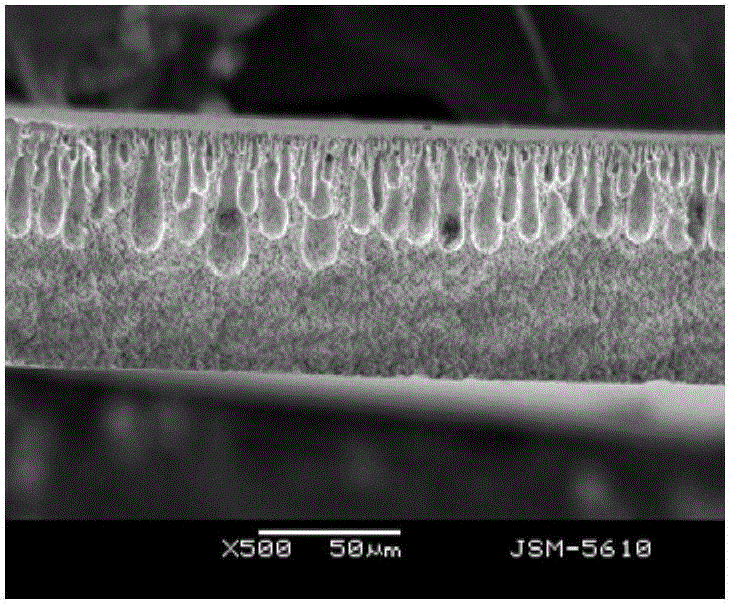

Nano-silver/graphene/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

A technology of polyvinylidene fluoride and graphene, which is applied in the field of nanocomposite materials and ultrafiltration membranes, can solve the problems of increasing operating costs, shortening the service life of membranes, and irreversible attenuation, and achieves good antibacterial and anti-pollution properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] ① Disperse graphene oxide and polyethylene glycol ultrasonically (frequency 100Hz) in N,N-dimethylacetamide at 60°C, the ratio of graphene oxide mass to N,N-dimethylacetamide volume is 10g / L, the ratio of polyethylene glycol mass to N,N-dimethylacetamide volume is 12g / L. The oxygen content of the graphene oxide used is 14.6 wt%, and the molecular weight of the polyethylene glycol used is 800.

[0048] ② AgNO at 60℃ 3 , polyethylene glycol dissolved in N,N-dimethylacetamide, AgNO 3 The ratio of the mass to the volume of N,N-dimethylacetamide is 25g / L, and the ratio of the mass of polyethylene glycol to the volume of N,N-dimethylacetamide is 12g / L. The oxygen content of the graphene oxide used is 14.6 wt%, and the molecular weight of the polyethylene glycol used is 800.

[0049] ③ The solution prepared in step ① was mixed with the solution prepared in step ② in equal volumes, and treated with ultrasound (frequency 100 Hz) at 60° C. for 3 hours to prepare a nano-silver...

Embodiment 2

[0053] ① Disperse graphene oxide and polyethylene glycol ultrasonically (frequency 100Hz) in N,N-dimethylacetamide at 60°C. The ratio of graphene oxide mass to N,N-dimethylacetamide volume is 8g / L, the ratio of polyethylene glycol mass to N,N-dimethylacetamide volume is 15g / L. The oxygen content of the graphene oxide used is 16.3 wt%, and the molecular weight of the polyethylene glycol used is 2000.

[0054] ② AgNO at 60℃ 3 , polyethylene glycol dissolved in N,N-dimethylacetamide, AgNO 3 The ratio of mass to N,N-dimethylacetamide volume is 20g / L, and the ratio of polyethylene glycol mass to N,N-dimethylacetamide volume is 15g / L. The oxygen content of the graphene oxide used is 14.6 wt%, and the molecular weight of the polyethylene glycol used is 2000.

[0055] ③ The solution prepared in step ① was mixed with the solution prepared in step ② in equal volumes, and treated with ultrasound (frequency 100 Hz) at 60° C. for 3 hours to prepare a nano-silver / graphene composite solu...

Embodiment 3

[0059] ① Disperse graphene oxide and polyethylene glycol ultrasonically (frequency 100Hz) in N,N-dimethylacetamide at 60°C, the ratio of graphene oxide mass to N,N-dimethylacetamide volume is 6g / L, the ratio of polyethylene glycol mass to N,N-dimethylacetamide volume is 18g / L. The oxygen content of the graphene oxide used is 19.2 wt%, and the molecular weight of the polyethylene glycol used is 4000.

[0060] ② AgNO at 60℃ 3 , polyethylene glycol dissolved in N,N-dimethylacetamide, AgNO 3 The ratio of the mass to the volume of N,N-dimethylacetamide is 17g / L, and the ratio of the mass of polyethylene glycol to the volume of N,N-dimethylacetamide is 18g / L. The oxygen content of the graphene oxide used is 19.2 wt%, and the molecular weight of the polyethylene glycol used is 4000.

[0061] ③ The solution prepared in step ① was mixed with the solution prepared in step ② in equal volumes, and treated with ultrasound (frequency 100 Hz) at 60° C. for 3 hours to prepare a nano-silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com