Preparation method of composite separation membrane

A separation membrane and basement membrane technology, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh 25g PVDF, dissolve it in 75g DMF solvent, stir in a water bath at 80°C for 4 hours to completely dissolve it, and degas in a vacuum oven at 80°C to obtain a casting solution. Scrape the film-forming liquid evenly on the glass plate with a squeegee, and place it in a closed environment with a constant temperature of 50°C and a relative humidity of 80% until it is cured and formed to obtain the base film;

[0026] 2) Put the cured PVDF flat film, the base film, together with the glass plate into deionized water. After the base film falls off the glass plate, soak it in deionized water for 24 hours, and then put the base film into a freeze dryer. Store it after freeze-drying at room temperature for 48 hours;

[0027] 3) Place the dried base film on the sample stage in the sputtering chamber, take nickel as the target, and the distance between the nickel target and the base film is 10cm, use a water cooling device to cool the base film, and first draw the reaction chamb...

Embodiment 2

[0034] 1) Weigh 25g PVDF, dissolve it in 75g DMF solvent, stir in a water bath at 80°C for 4 hours to completely dissolve it, and degas in a vacuum oven at 80°C to obtain a casting solution. Scrape the film-forming liquid evenly on the glass plate with a squeegee, and place it in a closed environment with a constant temperature of 50°C and a relative humidity of 80% until it is cured and formed to obtain the base film;

[0035] 2) Put the cured PVDF flat film, the base film, together with the glass plate into deionized water. After the base film falls off the glass plate, soak it in deionized water for 24 hours, and then put the base film into a freeze dryer. Store it after freeze-drying at room temperature for 48 hours;

[0036] 3) Place the dried base film on the sample stage in the sputtering chamber, take nickel as the target, and the distance between the nickel target and the base film is 10cm, use a water cooling device to cool the base film, and first draw the reaction chamb...

Embodiment 3

[0039] 1) Weigh 25g PVDF, dissolve it in 75g DMF solvent, stir in a water bath at 80°C for 4h to completely dissolve, and defoam in a vacuum oven at 80°C to obtain a casting solution. Scrape the film-forming liquid evenly on the glass plate with a squeegee, and place it in a closed environment with a constant temperature of 50°C and a relative humidity of 80% until it is cured and formed to obtain the base film;

[0040] 2) Put the cured PVDF flat film, the base film, together with the glass plate into deionized water. After the base film falls off the glass plate, soak it in deionized water for 24 hours, and then put the base film into a freeze dryer. Store it after freeze-drying at room temperature for 48 hours;

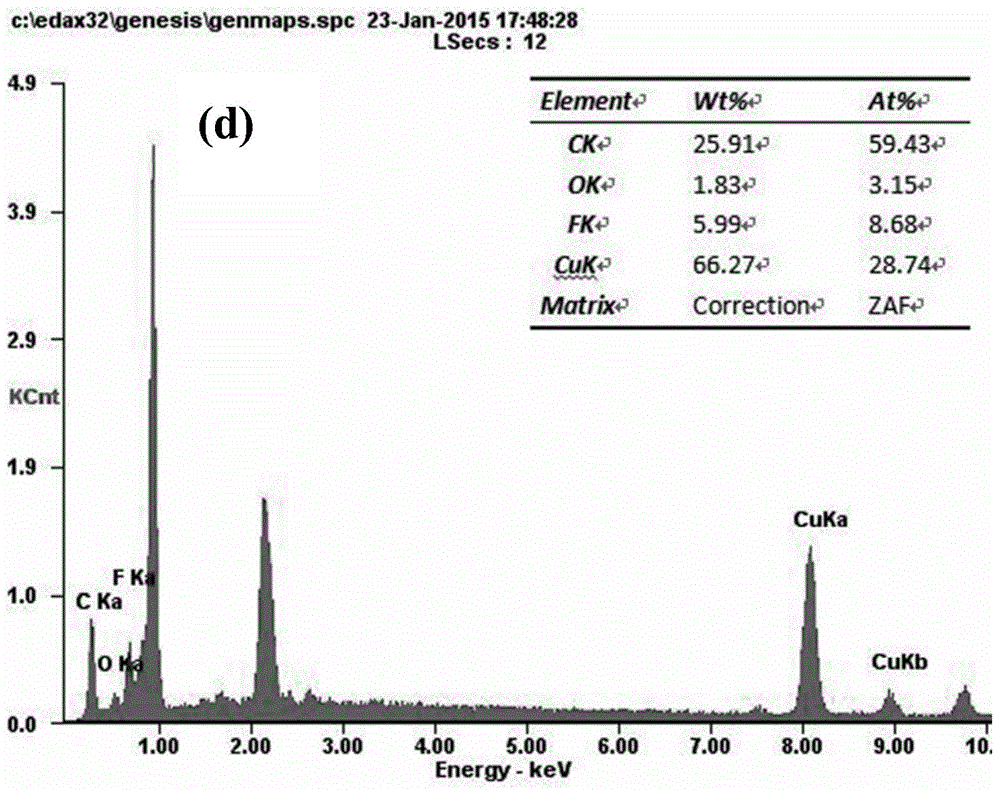

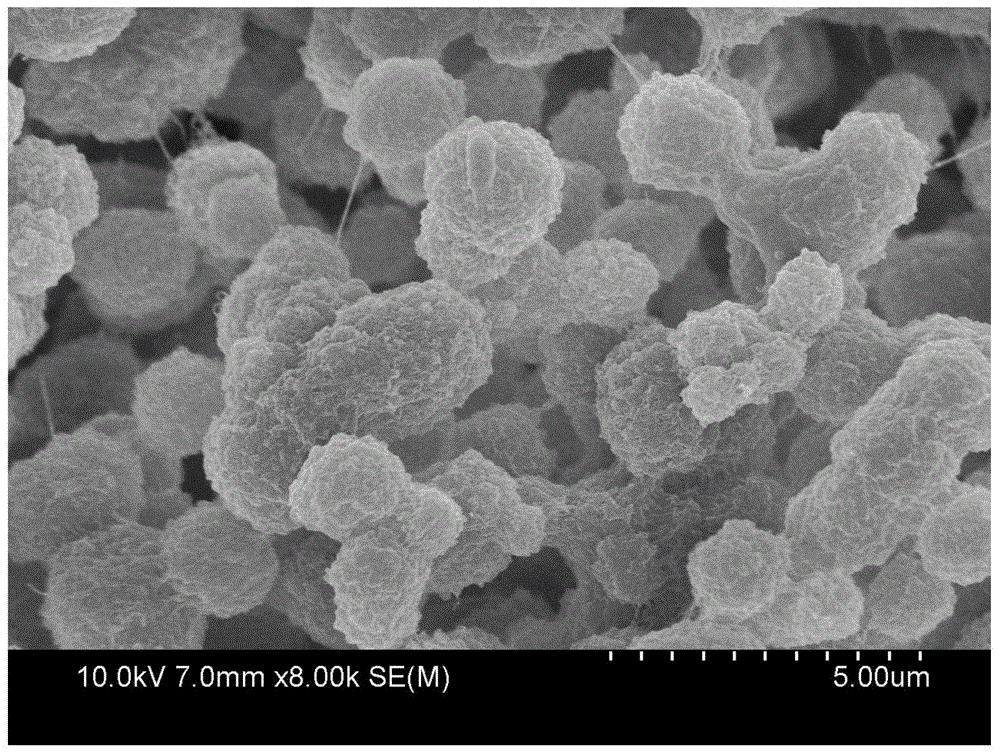

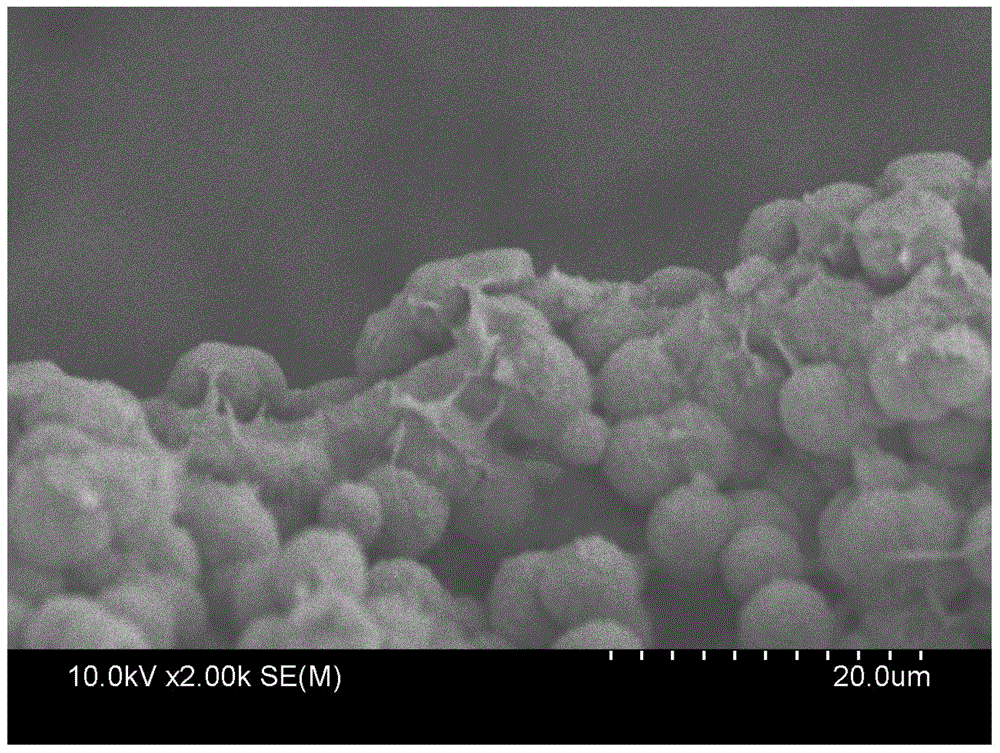

[0041] 3) Place the dried base film on the sample stage in the sputtering chamber, take copper as the target, and the distance between the copper target and the base film is 10cm, and use a water-cooling device to cool the base film, and first draw the reaction chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Surface specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com