Fiber tube reinforced hollow fiber composite biofilm as well as preparation method and application thereof

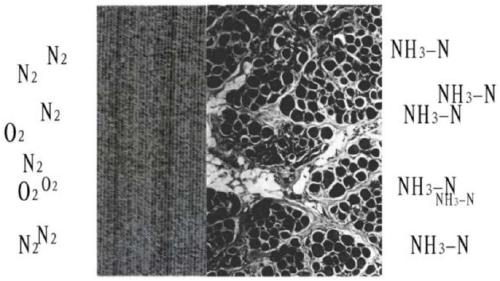

A fiber composite and reinforced technology, which is applied in the field of fiber tube reinforced hollow fiber composite biomembrane and its preparation, can solve the problems of inability to form a stable ecosystem and the absence of bioaggregation, and achieve the purpose of inhibiting the penetration of CO2 and providing good support function, the effect of improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of Fiber Tube Reinforced Hollow Fiber Composite Biofilm

[0032] First, immerse the fiber braided tube in sodium hydroxide aqueous solution to remove the oil stains on the braided tube; then use deionized water to clean the residual sodium hydroxide on the surface of the braided tube, and finally dry the braided tube for use.

[0033] Casting solution formula: in terms of mass percentage, the raw material components are:

[0034]

[0035] Wherein the pore-forming agent is polyvinylpyrrolidone, and the nanoparticles are titanium dioxide.

[0036] The casting solution was added into a stirring tank, stirred and dissolved at 40°C for 12 hours, then transferred to a defoaming tank, and left in the defoaming tank at 40°C for 4 hours to obtain a homogeneous casting solution. The degassed homogeneous casting solution is squeezed from the degassing tank into the spinneret under nitrogen pressure, and the pretreated braided tube passes through the cent...

Embodiment 2

[0037] Embodiment 2: Observation of membrane structure morphology

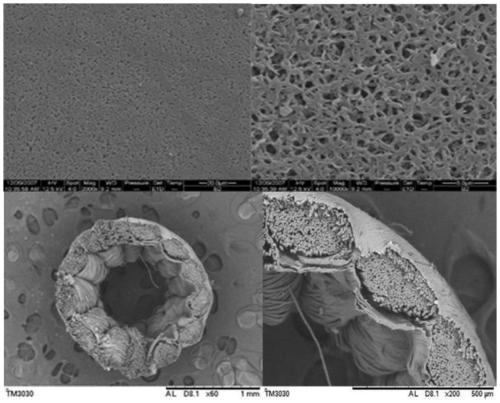

[0038] The cross-section and inner and outer surfaces of the prepared fiber tube-reinforced hollow fiber composite biofilm were observed by scanning electron microscope. The specific steps are: (1) immerse the wet fiber tube reinforced hollow fiber composite biofilm sample in liquid nitrogen for freezing and brittle fracture; (2) soak the broken membrane in 50%, 75%, and 100% concentration of Carry out dehydration in alcohol, immersion time is 1 hour respectively, then air-dry naturally in the air; (3) fix film sample on the sample stage, and gold-plate in cathodic vacuum sputtering device; (4) prepare The sample was sent to the scanning electron microscope observation platform for observation and photography, and the results were as follows: figure 1 shown.

Embodiment 3

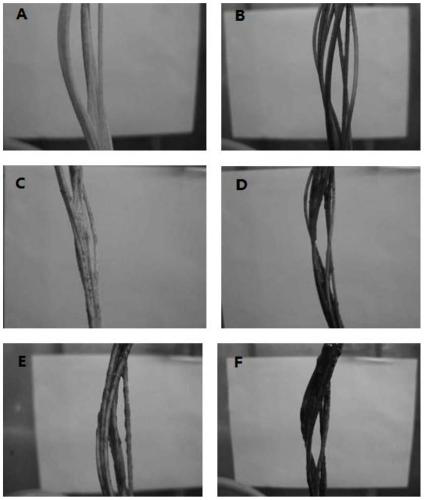

[0039] Embodiment 3: the mensuration of membrane inner and outer diameter and wall thickness

[0040]The inner and outer diameters and wall thickness of the fiber tube-reinforced hollow fiber composite biofilm were measured by an optical microscope with a ruler. The specific method is to cut the wet fiber tube reinforced hollow fiber composite biomembrane vertically with a blade, and keep the flatness of the cross section of the membrane filament, and read the inner and outer diameters of the fiber with the built-in ruler under the BZ61 binocular optical microscope. Under each spinning condition, 5 samples were taken for measurement, and the inner and outer diameters were averaged.

[0041] After testing, the fiber tube-reinforced hollow fiber membrane prepared in Example 1 has an inner diameter of 0.8 mm and an outer diameter of 2.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com