Preparation method for amphipathic triblock copolymer modified polyvinylidene fluoride membrane

A polyvinylidene fluoride membrane and copolymer modification technology, which is applied in the field of material science, can solve the problems of low rejection rate, etc., and achieve the effect of improved hydrophilicity, easy operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

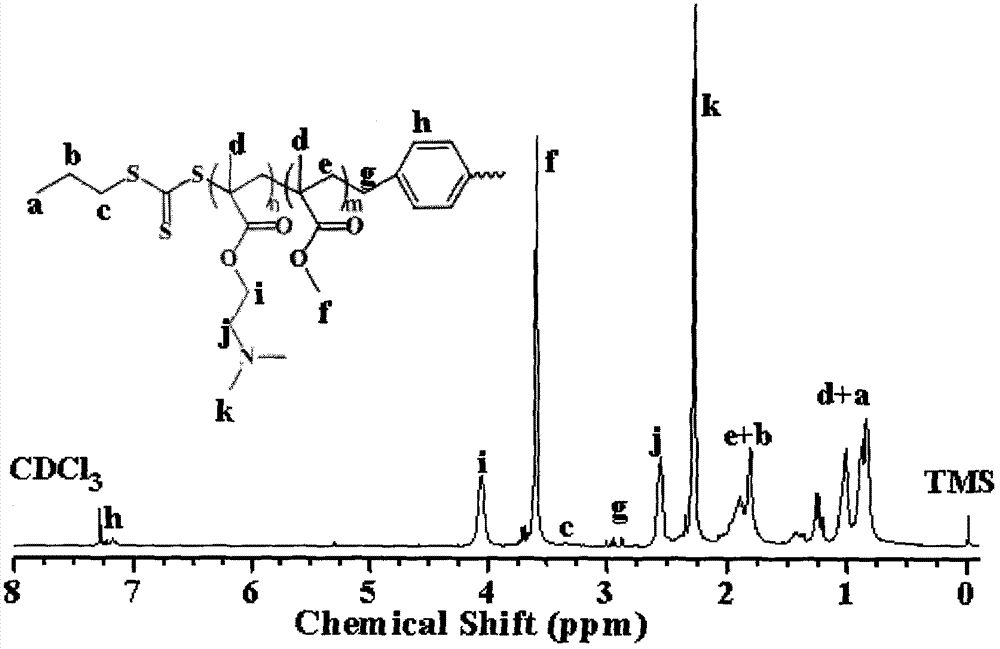

[0031] (1) Preparation of PDMD

[0032] First prepare PMMA-CTA: add 15g MMA, 0.761g RAFT reagent (CTA), 0.12g initiator A, 70mL solvent B into a 200mL reaction tube, put it in an ice-water bath and vacuumize for 30min, and remove the air in the reaction tube. Freeze the solvent with liquid nitrogen, use a double-row tube to evacuate and pass argon three times, and react in an oil bath at 70°C for 24 hours. The resulting substance was precipitated with 500 mL of n-hexane, filtered with suction, and the solid was collected and dried in vacuum to obtain yellow PMMA-CTA.

[0033]Then add 5g DMAEMA, 5g PMMA-CTA, 41mg AIBN, 40mL toluene into the 100mL reaction tube, put it into an ice-water bath and vacuumize for 30min, and remove the air in the reaction tube. Freeze the solvent with liquid nitrogen, use a double-row tube to evacuate and fill with argon three times, and react in an oil bath at 70°C for 24 hours. The obtained substance was precipitated with 500 mL of ice n-hexane, ...

Embodiment 2

[0041] (1) Preparation of PMDM:

[0042] First, add 10g of refined DMAEMA, 0.5075g of RAFT reagent (CTA), 82mg of initiator AIBN, and 70mL of toluene into a 200mL reaction tube, put it in an ice-water bath and vacuumize for 30min, and remove the air in the reaction tube. Freeze the solvent with liquid nitrogen, use a double-row tube to evacuate and pass argon three times, and react in an oil bath at 60°C for 24 hours. Part of the solvent was removed by rotary evaporation, and precipitated with 500 mL of n-hexane, filtered with suction, and the solid was collected and vacuum-dried at 40°C to obtain PDMAEMA-CTA as a light yellow solid. Then add 7.9g PDMAEMA-CTA, 7.9g MMA, 64.8mg AIBN, and 40mL toluene into a 100mL reaction tube, put it in an ice-water bath and vacuumize for 30min, and remove the air in the reaction tube. Freeze the solvent with liquid nitrogen, use a double-row tube to evacuate and fill with argon three times, and react in an oil bath at 60°C for 24 hours. Par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com