Ag@NH2-MIL-125/polyarylether sulfone hybrid dense reactive ultrafiltration membrane and preparation method thereof

A NH2-MIL-125, polyarylene ether technology, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve the problems of shortened life of ultrafiltration membrane components, increased cleaning and replacement frequency, and decreased separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides an Ag@NH 2 -MIL-125 / polyarylethersulfone hybrid dense reactive ultrafiltration membrane and its preparation method, including:

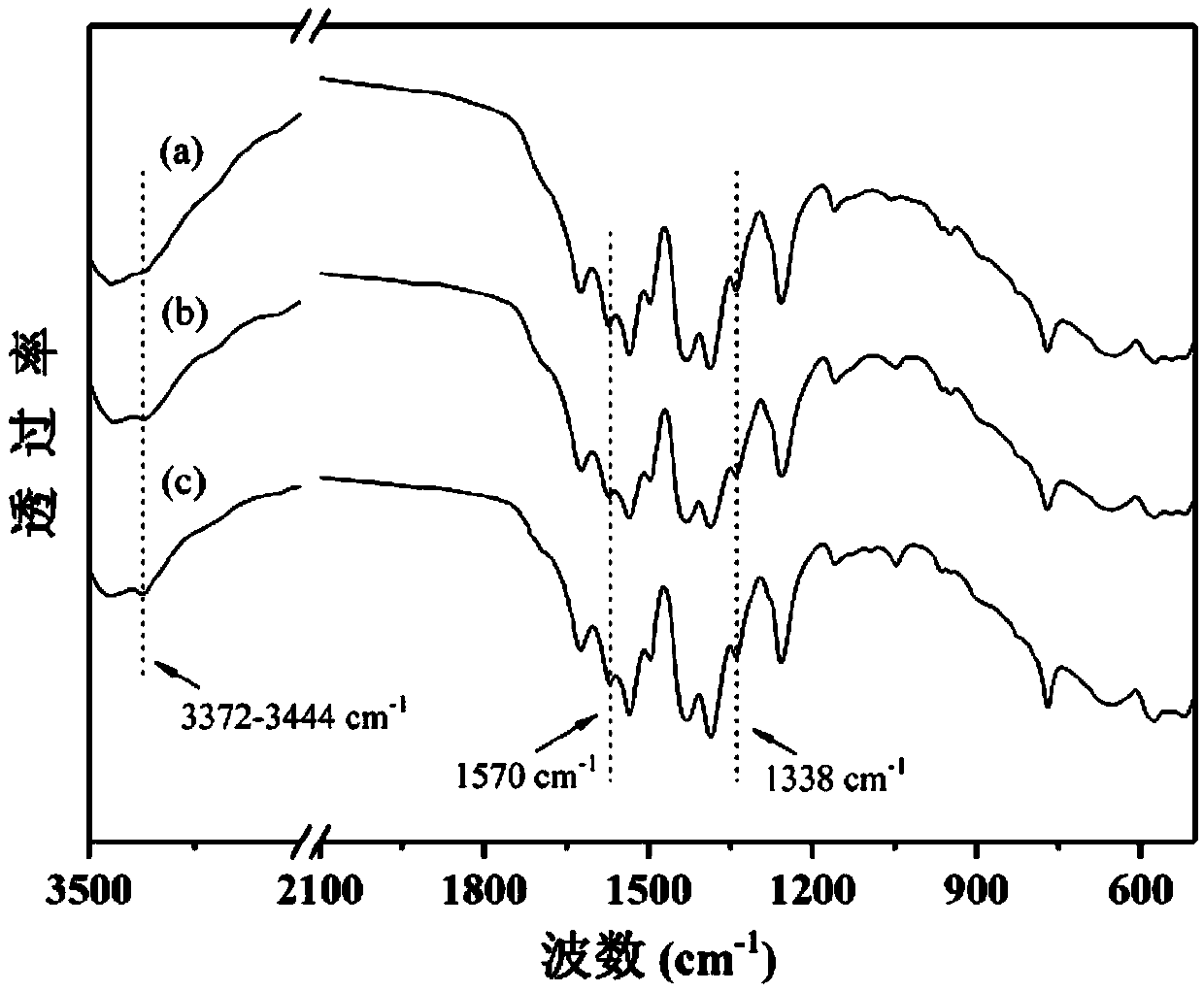

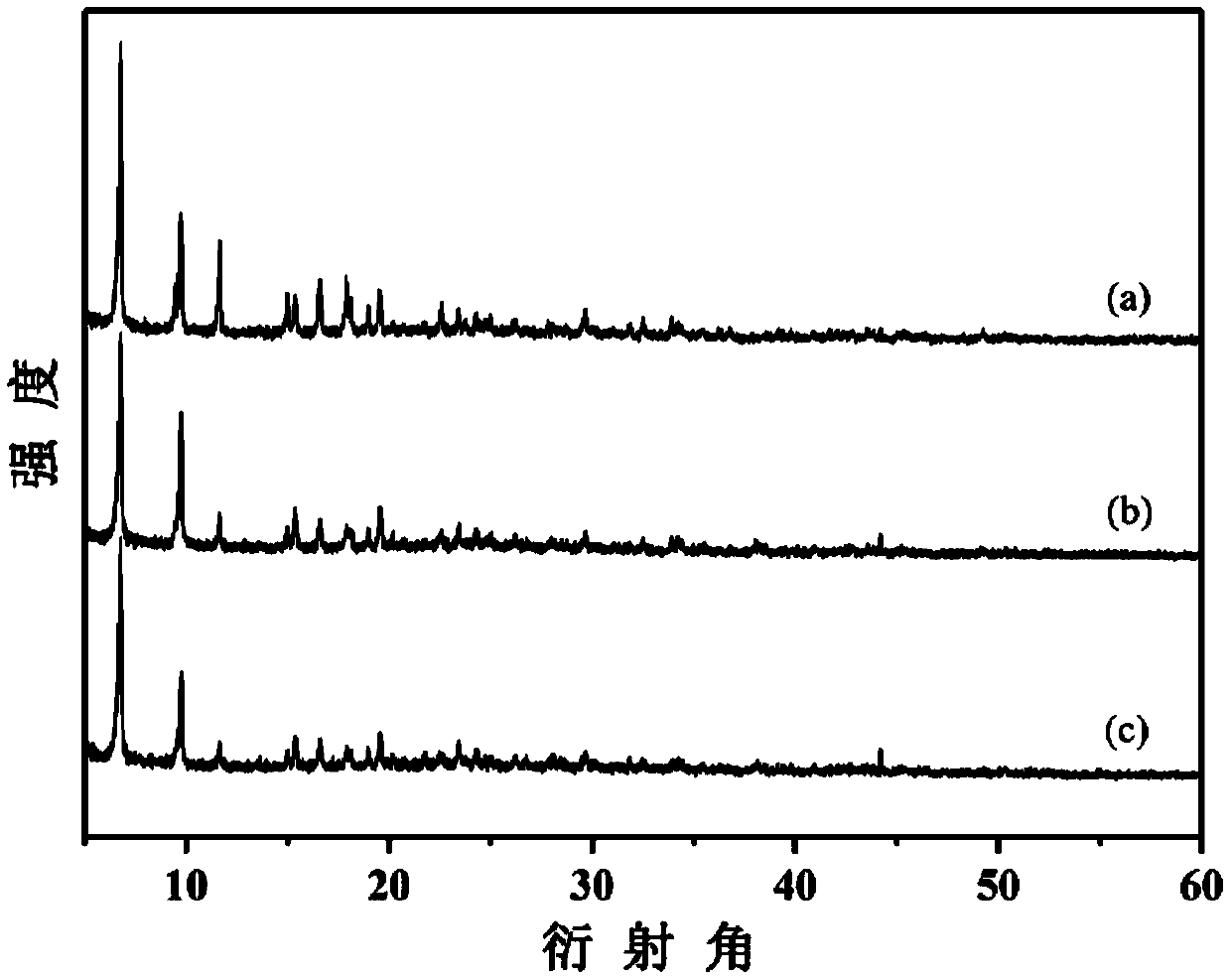

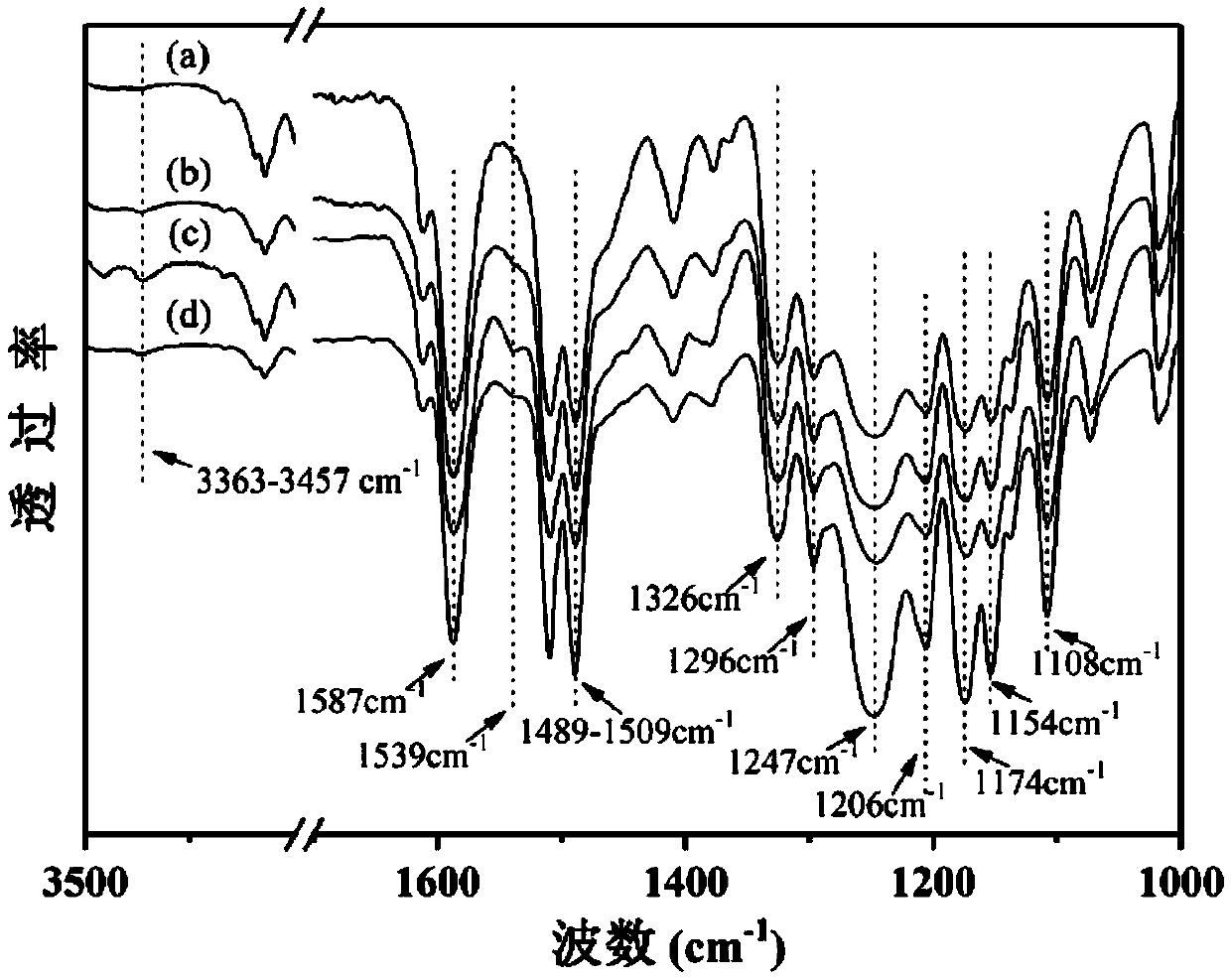

[0031] Step 1: Dissolve butyl titanate and 2-aminoterephthalic acid in a mixed solution of methanol and N,N-dimethylformamide, stir at room temperature for 6-10 hours, then transfer to a reaction kettle and put Put it into the temperature-programmed oven at 150°C-160°C for 24-48 hours. After the reaction, the powdery product generated in the reactor is separated by high-speed centrifugation, and then washed with methanol and N,N-dimethylformamide for several times. times and then dried and ground to obtain NH 2-MIL-125 material. According to the present invention, the molar ratio of butyl titanate to 2-aminoterephthalic acid is preferably 1:4; the volume ratio of methanol to N,N-dimethylformamide is preferably 1:1.

[0032] Step 2: Incorporate AgNO 3 Dissolve in deionized water, then add the powder obtained in step 1...

Embodiment 1

[0044] 1) Dissolve 2-aminoterephthalic acid (0.009mol, 1.5g) and butyl titanate (0.00225mol, 0.84mL) in a mixture of methanol (5mL) and N,N-dimethylformamide (5mL) The solution was stirred at room temperature for 6 hours until it was completely dissolved, and the obtained solution was sonicated for 5 minutes, then transferred to a 40 mL polytetrafluoroethylene-lined high-temperature and high-pressure reactor, and placed in a temperature-programmed oven. Set the temperature-programmed oven to raise the temperature to 150°C at a rate of 2°C / min, keep it for 24 hours and then cool to room temperature. Transfer the resulting product to a 50mL centrifuge tube, centrifuge at 800 rpm for 10 minutes, pour off the supernatant, add 20mL N,N-dimethylformamide and stir for 2 hours, then centrifuge at the same speed and time Finally, pour off the supernatant, repeat 3 times, then add 20mL methanol and continue washing 3 times in the same way to complete the washing step. Finally, the prod...

Embodiment 2

[0053] 1) the method described in 1) of embodiment 1 makes NH 2 - MIL-125 material;

[0054] 2) Take 0.096g AgNO 3 Dissolve in deionized water, and make up to 100mL, add 2g of the above NH 2 - MIL-125 material, after stirring evenly, sonicate for 5 minutes, transfer the above mixture to a quartz photoreactor, place the photoreactor in a water bath circulation container equipped with temperature control to start stirring, and use a 300W xenon lamp to irradiate for 45 minutes. After the obtained product was washed with deionized water for 3 times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours, cooled to room temperature, and then ground to obtain NH with a mass fraction of 3% loaded silver. 2 -MIL-125 photocatalytic material, named: 3%Ag@NH 2 -MIL-125.

[0055] 3) The method described in 3) of Example 1 makes polyarylethersulfone matrix material (PAES-CF 3 -COOH).

[0056] 4) As described in 4) of Example 1, using the 3% Ag@NH prepared above 2 -MIL-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com