Amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane and preparation method thereof

A polymer, triblock technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult removal of metal salt catalysts, strong hydrophobicity of PVDF membrane, irreversible pollution, etc. Water-based and anti-pollution properties, wide application range, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

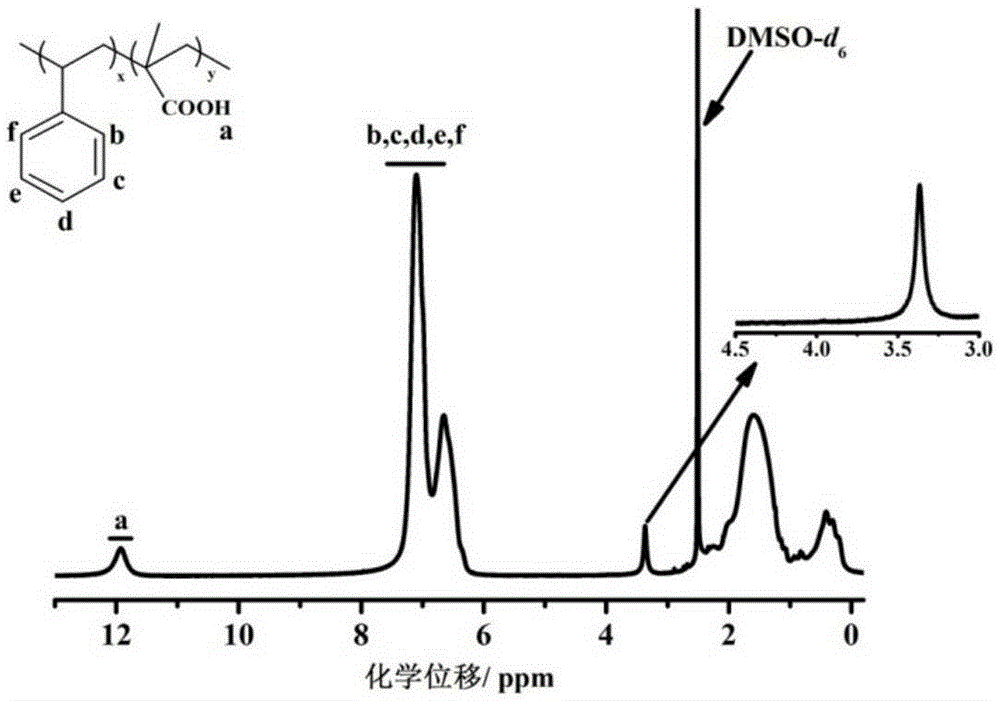

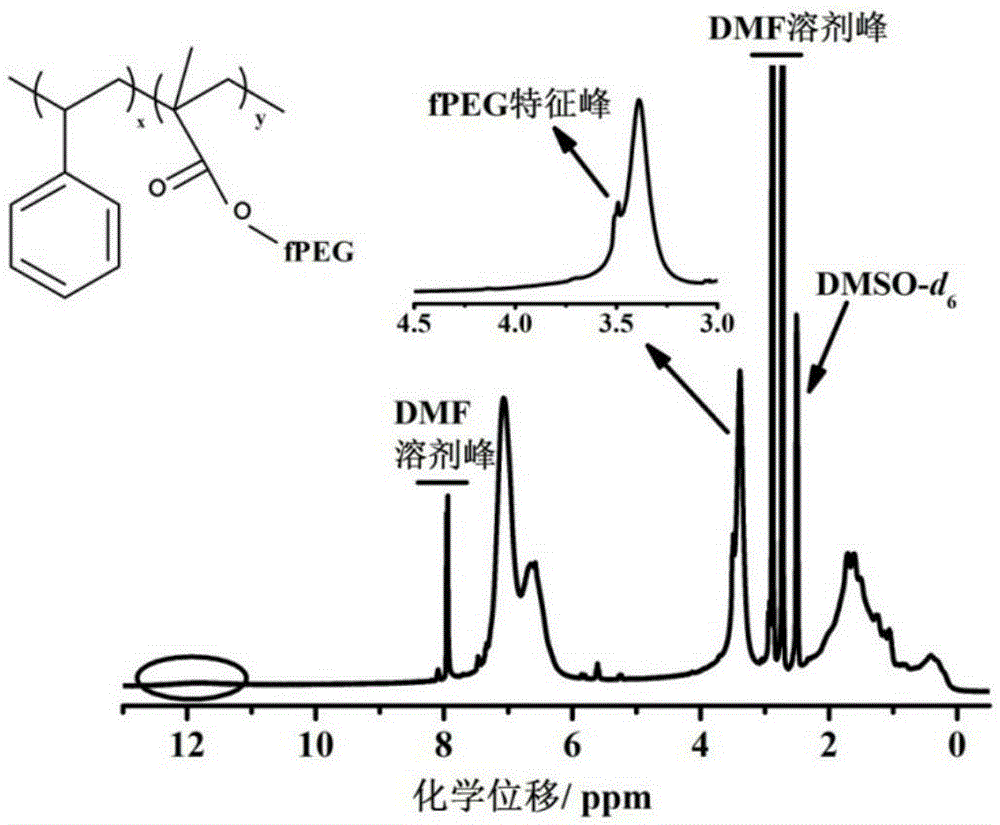

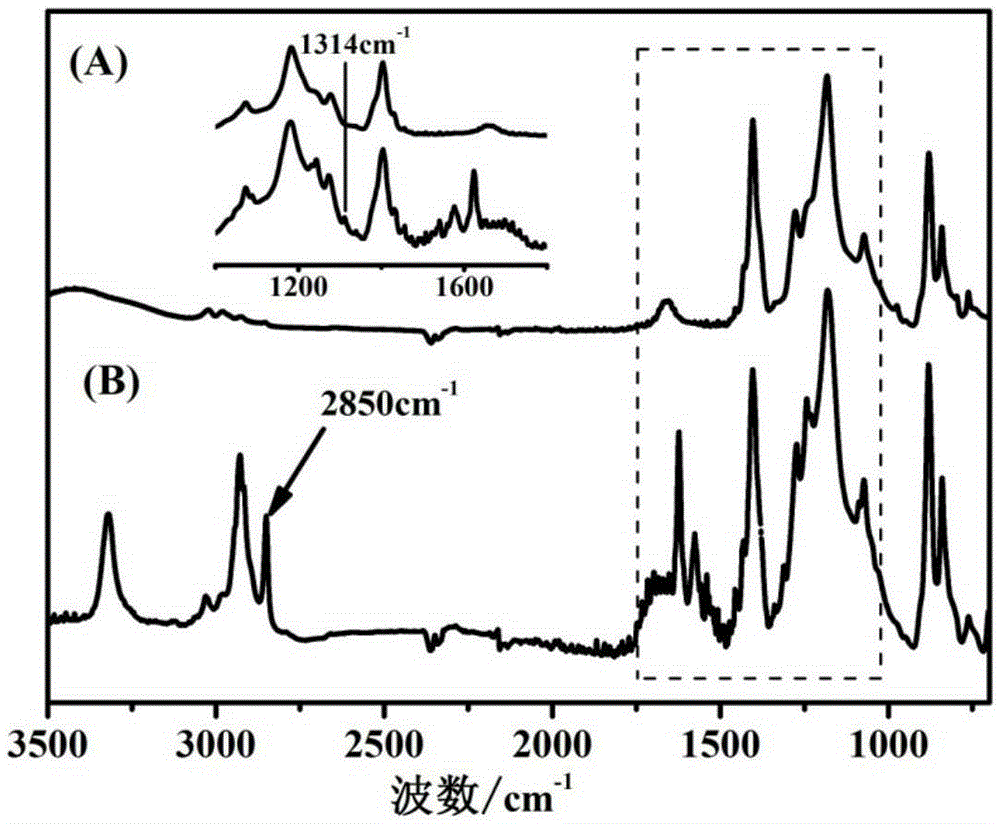

[0036] A method for preparing an amphiphilic triblock polymer modified PVDF ultrafiltration membrane, which uses PSxMAAy-g-fPEGz as an additive to modify PVDF to form a membrane to obtain an amphiphilic triblock polymer modified PVDF ultrafiltration membrane, among them, PS x MAA y -g -fPEG z Prepared by the following synthetic route:

[0037]

[0038] Specifically made through the following steps:

[0039] Weigh 10gPVP, 3.6~13.9gPS x MAA y -g -fPEG z , 154g NMP in a beaker, fully stirred at 80°C for 24 hours to completely dissolve it;

[0040] Add 32.4g PVDF and continue stirring to ensure that all reactants are completely dissolved to form a uniform casting solution;

[0041] Let the casting solution st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com