Preparation of Y2O3: Eu3+ nanosphere powder

A nanosphere and powder technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of poor powder luminescence performance, reduced luminescence intensity, numerous and complicated processes, etc., and achieve easy control of structure and dispersion. The effect of good performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

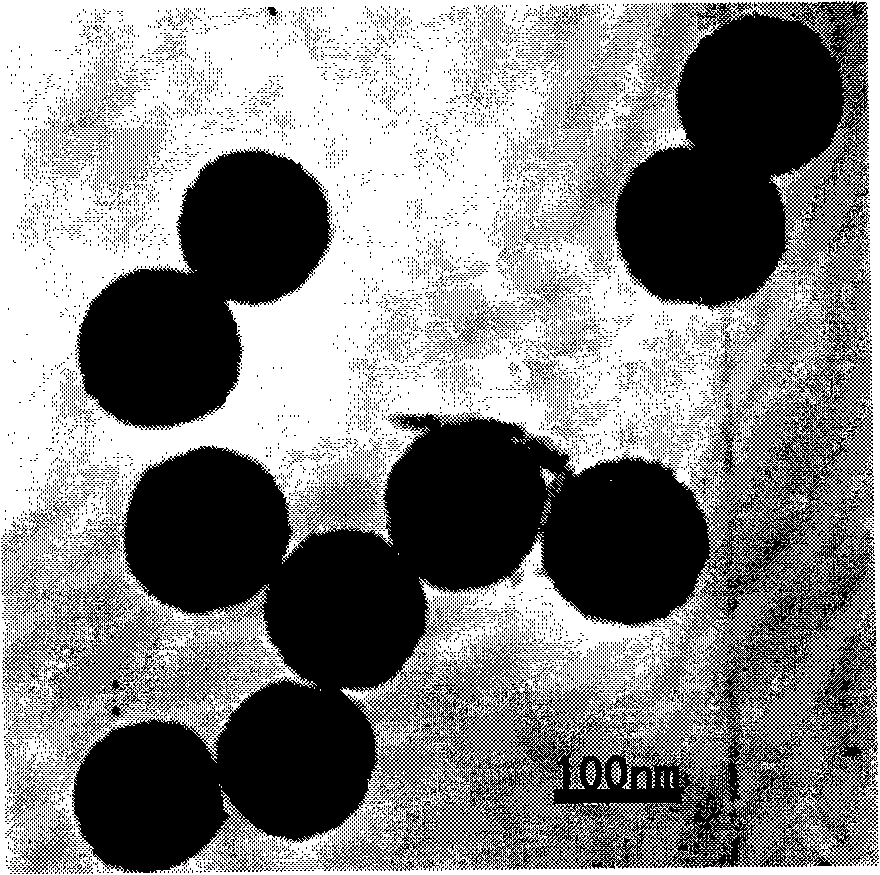

[0017] (1) Take the following raw materials in chemical mass respectively: 1.0mmol of yttrium nitrate; 0.05mmol of europium nitrate; 20mmol of urea; 0.1mmol of hexadecyltrimethylammonium bromide; In ionized water, a mixed solution is obtained; in this solution, the concentration of yttrium nitrate is 25mmol / L, the concentration of europium nitrate is 1.25mmol / L, and the concentration of urea is 500mmol / L; in addition, add surfactant 0.1mmol;

[0018] (2) Transfer the above-mentioned mixed solution to a round-bottomed flask, and heat to reflux for 50 minutes under stirring with a magnetic stirrer; the heating temperature is 105°C; then cool to room temperature, and centrifuge the resulting white precipitate, and then Wash 3 times with deionized water to remove excess surfactant, and then wash 1 time with absolute ethanol; then dry in an oven at 60°C to obtain a white powder;

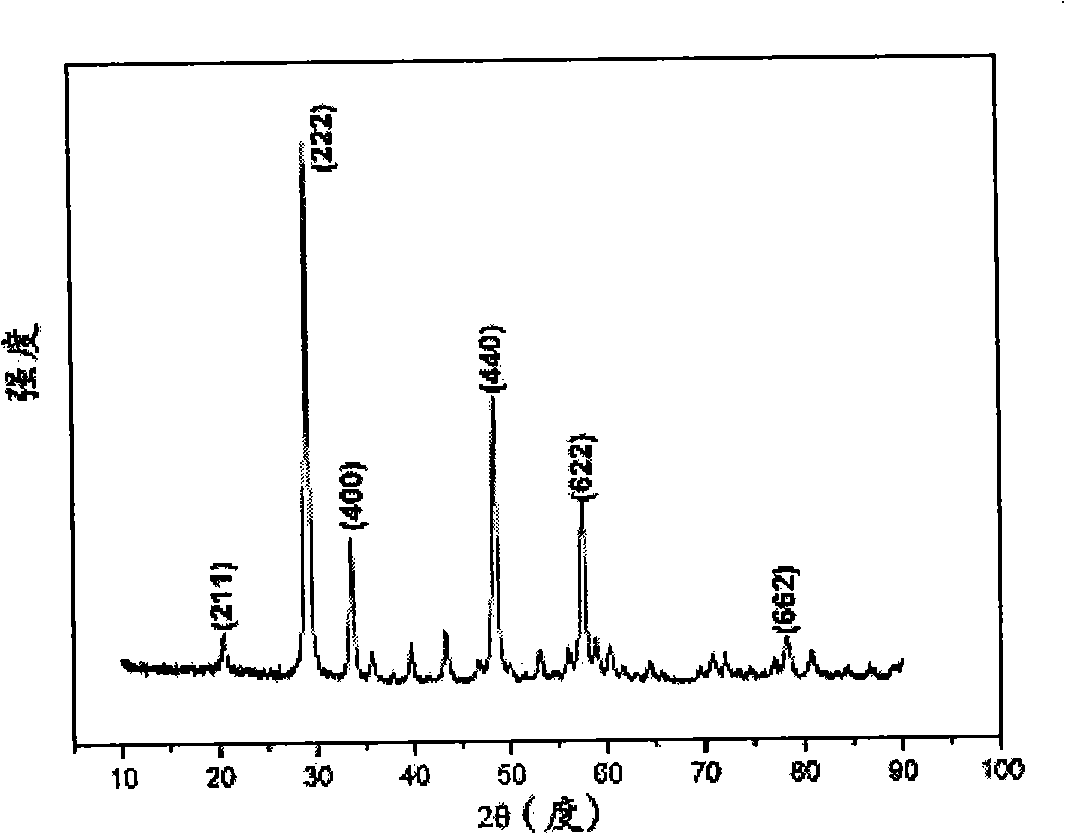

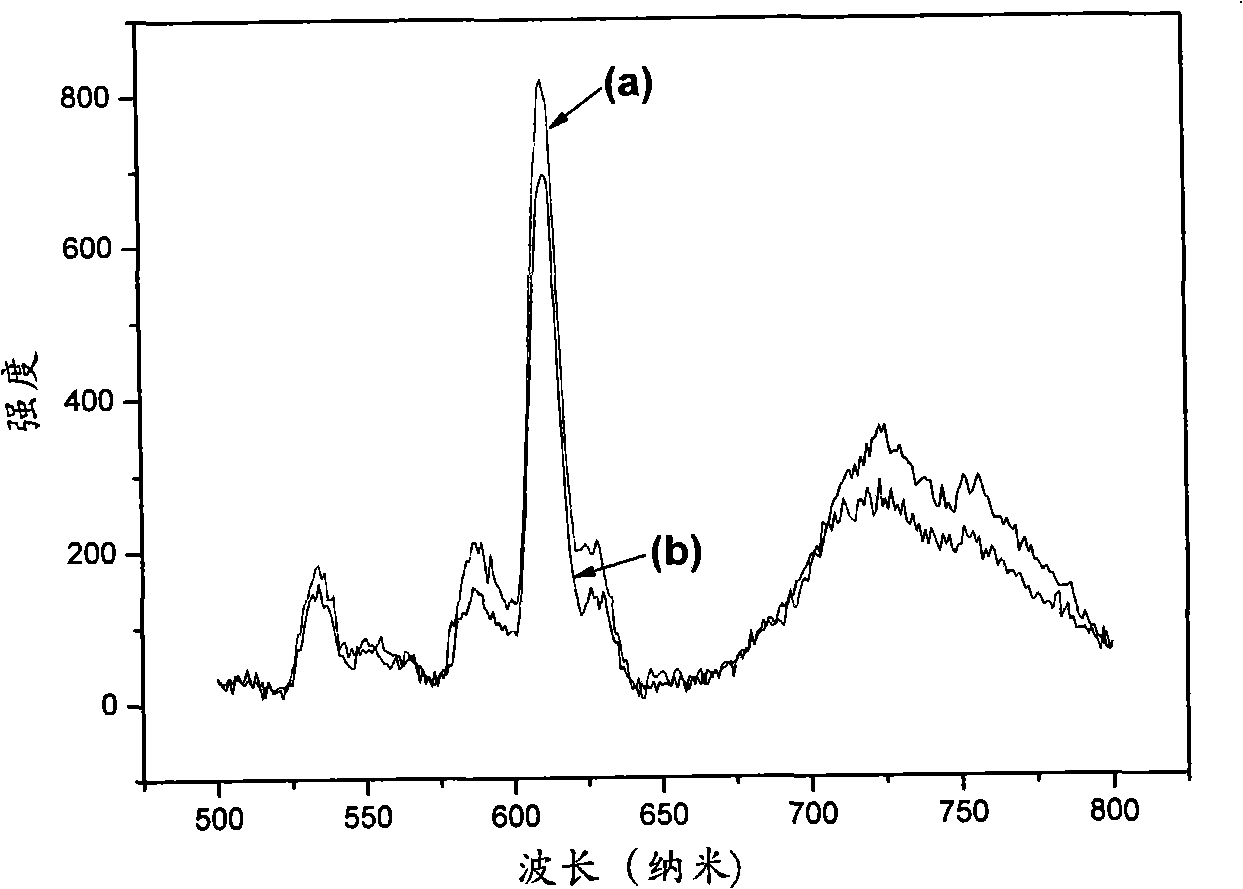

[0019] (3) The powder obtained after the above-mentioned drying is raised to 600° C. at a heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com