Method for synchronously preparing hollow fiber compound nanofiltration membrane through immersion precipitation phase inversion/interface crosslinking

A technology of immersion precipitated phase and interfacial crosslinking, which is applied in the field of synchronous preparation of hollow fiber composite nanofiltration membranes by immersion precipitated phase inversion/interface crosslinking, can solve the problems that limit the development of hollow fiber composite nanofiltration membranes, and achieve simple and easy performance , simple process and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

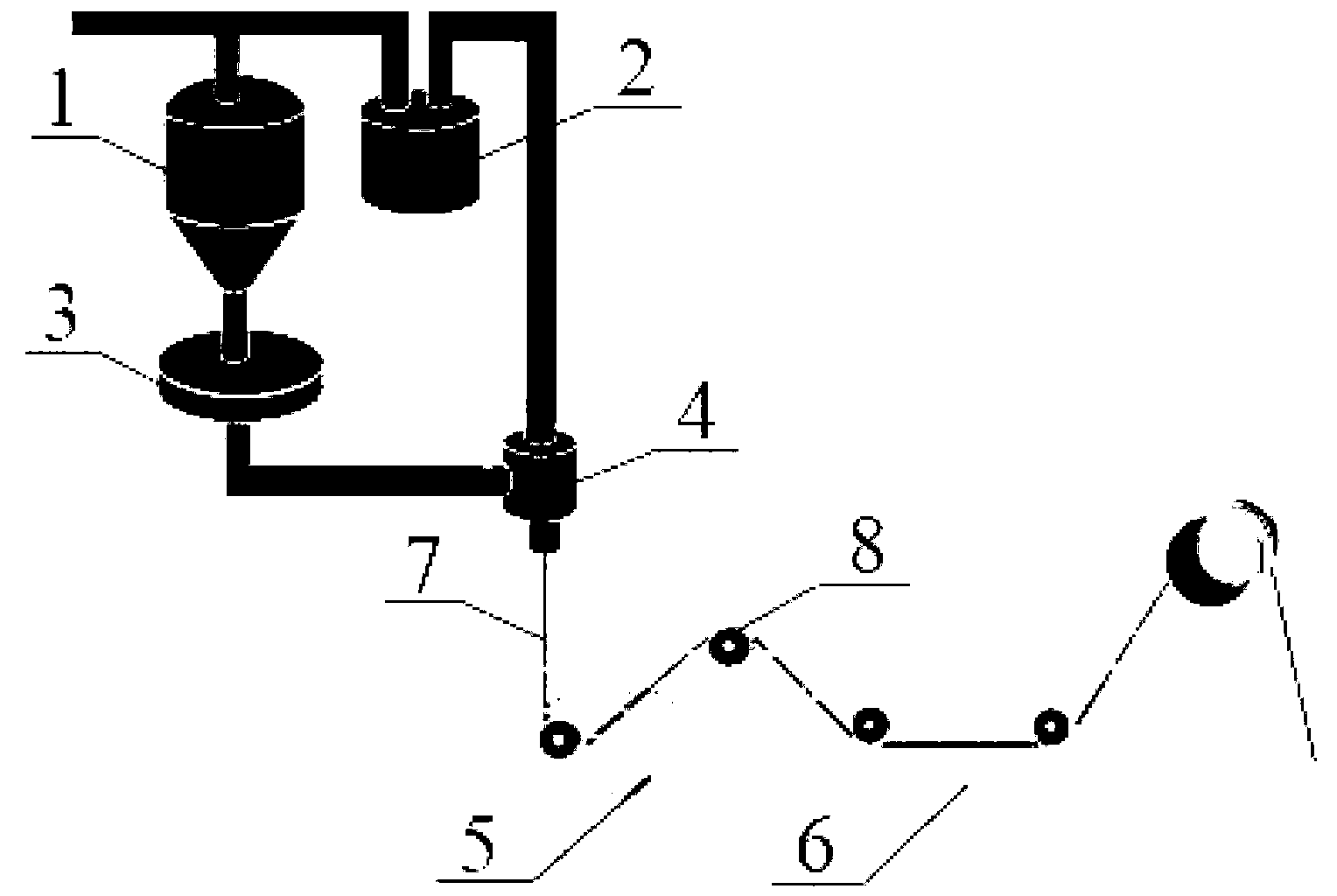

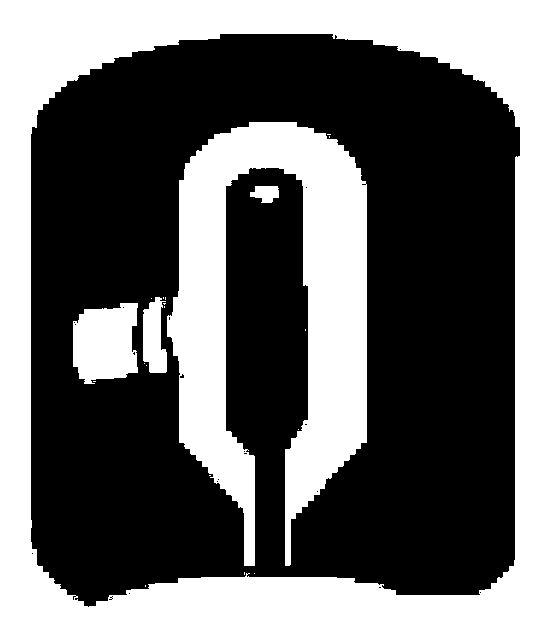

Embodiment 1

[0029] Select polyvinylidene fluoride and polyvinylpyrrolidone with a mass ratio of 10:1:1 (the number average molecular weight is 1×10 3 ) and p-dichlorobenzyl, mixed with DMF, stirred and dissolved at 50°C to form a homogeneous solution, left standing for defoaming, to obtain a film casting solution with a mass percentage concentration of polyvinylidene fluoride of 15%; at 40°C, PDMAEMA Stir and dissolve in water, prepare a PDMAEMA aqueous solution with a concentration of 5g / L, let it stand for defoaming, and use it as the core liquid. The casting liquid and the core liquid are simultaneously extruded through the annular spinning head of the submerged precipitation phase inversion spinning device under the pressure of 0.1 MPa and the spinning speed of 10 m / min to form a tubular liquid film, and the tubular liquid film passes through 1 cm of air After the gap, it enters a coagulation bath of 30°C water to make a hollow fiber nanofiltration membrane, and after soaking and wash...

Embodiment 2

[0040] Select polyvinylidene fluoride and polyvinylpyrrolidone with a mass ratio of 20:5:5 (the number average molecular weight is 3×10 3 ) and p-dichlorobenzyl, mixed with DMSO, stirred and dissolved at 70°C to form a uniform solution, left to defoam, and obtained a casting solution with a mass percentage concentration of polyvinylidene fluoride of 25%; at 60°C, PEI Stir and dissolve in water, prepare a PEI aqueous solution with a concentration of 15g / L, let it stand for defoaming, and use it as the core liquid. The casting liquid and the core liquid are simultaneously extruded through the annular spinning head of the submerged precipitation phase inversion spinning device under the pressure of 0.1 MPa and the spinning speed of 10 m / min to form a tubular liquid film, and the tubular liquid film passes through 1 cm of air After the gap, it enters a coagulation bath of 50°C water to make a hollow fiber nanofiltration membrane, and after soaking and washing in 15°C water for 48 ...

Embodiment 3

[0043] Select polyvinylidene fluoride, polyethylene glycol (number-average molecular weight: 100) and glutaraldehyde with a mass ratio of 30:10:2, mix them with DMAc, stir and dissolve at 50°C to form a uniform solution, let stand for defoaming, Obtain a casting liquid with a concentration of polyvinylidene fluoride of 35% by mass; stir and dissolve PEI in water at 40° C. to prepare a PEI aqueous solution with a concentration of 10 g / L, and let it stand for defoaming as a core liquid. The casting liquid and the core liquid are simultaneously extruded through the annular spinning head of the submerged precipitation phase inversion spinning device under the pressure of 0.3 MPa and the spinning speed of 20 m / min to form a tubular liquid film, and the tubular liquid film passes through 5 cm of air After the gap, enter the coagulation bath of 30°C water to make a hollow fiber nanofiltration membrane, and after soaking and washing in 15°C water for 48 hours, a polyvinylidene fluoride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com