Piezoelectric polyvinylidene fluoride porous membrane and preparation method thereof

A polyvinylidene fluoride and porous membrane technology is applied in the field of materials to achieve the effects of easy operation, wide selection range and simple industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

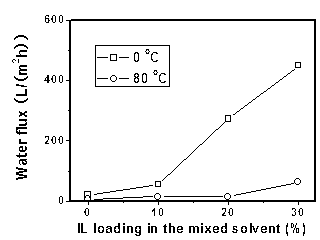

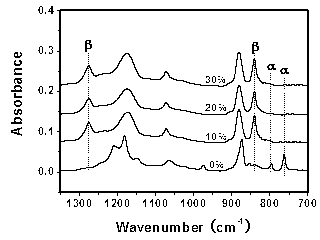

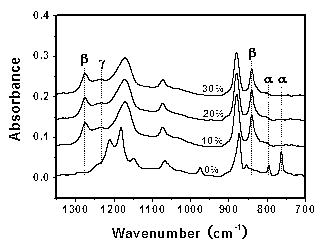

[0032] Weigh polyvinylidene fluoride, ionic liquid (1-butyl-3-methylimidazolium tetrafluoroborate) and N,N-dimethylformamide according to the ratio in Table 1, and the weighed N,N -Dimethylformamide Dissolve polyvinylidene fluoride at 95°C, then add ionic liquid and shake well to defoam. Pour the above solution on a glass plate and use a glass plate to scrape out a liquid film of about 200um, then immerse it in a water bath at 0 and 80°C for 20 minutes to obtain a polyvinylidene fluoride film, and then immerse it in deionized water and alcohol for 24 hours to remove the ionic liquid to obtain Piezoelectric polyvinylidene fluoride porous membrane.

[0033] Among them, in Examples 4 and 8, the performance of the porous membrane is further improved by adding inorganic fillers, which include carbon nanotubes, silicon dioxide and graphene; the added quality of the inorganic fillers is 10% of polyvinylidene fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com