Advanced treatment method of biochemical tail water of coking wastewater

A technology for coking wastewater and advanced treatment, which is applied in oxidation water/sewage treatment, metallurgical wastewater treatment, adsorbed water/sewage treatment, etc. Simple operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

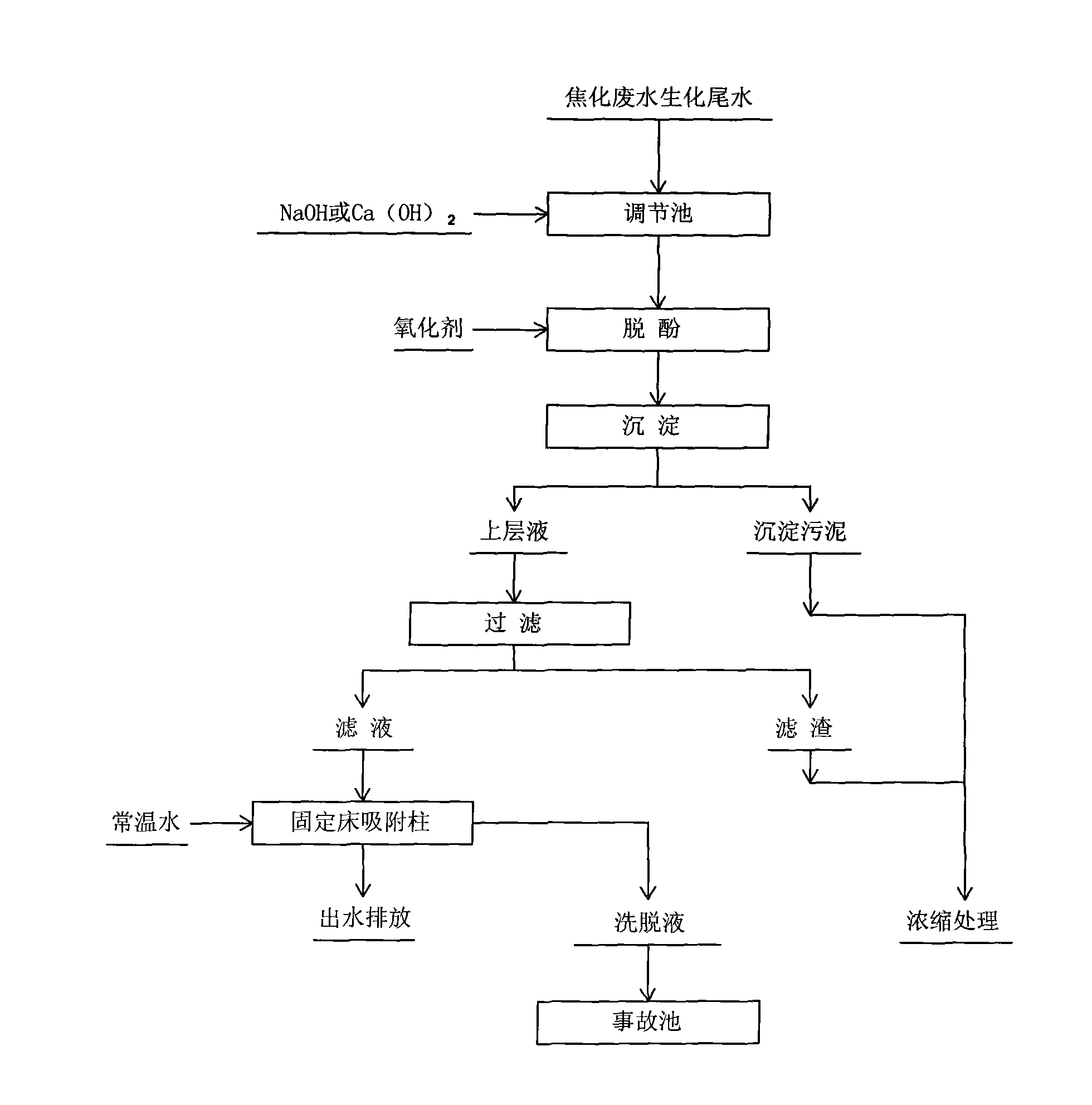

[0016] A method for advanced treatment of coking wastewater biochemical tail water, comprising the following steps:

[0017] Step 1 Catalytic Oxidation

[0018] The coking wastewater that has not reached the standard after biochemical treatment flows into the adjustment tank, and the pH is adjusted to 12 with sodium hydroxide at 10 ℃ ~ 30 ℃, and then potassium permanganate is added to carry out dephenolization reaction for 1 hour, and the dephenolization reaction mixture is precipitated for 0.5 hours. The supernatant liquid is drained and filtered, and the filtration separation technology can further remove colloidal organic matter and fine activated sludge particles, so that the COD of the effluent is reduced to 110mg / L, and the chromaticity is close to colorless; the filtered and separated filter residue and sedimentary sludge are concentrated together. deal with;

[0019] Step 2 Adsorption Treatment

[0020] The filtrate of step 1 was heated at 10°C to 30°C and the flow r...

Embodiment 2

[0024] A method for advanced treatment of coking wastewater biochemical tail water, comprising the following steps:

[0025] Step 1 Catalytic Oxidation

[0026] The coking wastewater that has not reached the standard after biochemical treatment flows into the adjustment tank, and the pH is adjusted to 11 with calcium hydroxide at 20 ℃ ~ 40 ℃, and then potassium ferrate is added to carry out dephenolization reaction for 2 hours, and the dephenolization reaction mixture is precipitated for 1 hour. The supernatant is drained and filtered, and the filtration and separation technology can further remove colloidal organic matter and fine activated sludge particles, so that the COD of the effluent is reduced to 115mg / L, and the chroma is close to colorless; the filtered residue and sedimentary sludge are concentrated together.

[0027] Step 2 Adsorption Treatment

[0028] The filtrate of step 1 was heated at 20℃~40℃ and the flow rate was 6m 3 Under the condition of / h, it passes th...

Embodiment 3

[0032] A method for advanced treatment of coking wastewater biochemical tail water, comprising the following steps:

[0033] Step 1 Catalytic Oxidation

[0034] The coking wastewater that has not reached the standard after biochemical treatment flows into the adjustment tank, and the pH is adjusted to 9 with sodium hydroxide at 10 ℃ ~ 40 ℃, and then ozone is added to carry out dephenolization reaction for 2 hours, the dephenolization reaction mixture is precipitated for 1.5 hours, and the supernatant The liquid is drained and filtered, and the filtration and separation technology can further remove colloidal organic matter and fine activated sludge particles, so that the COD of the effluent is reduced to 120mg / L, and the chromaticity is close to colorless; the filtered residue and sedimentary sludge are concentrated together;

[0035] Step 2 Adsorption Treatment

[0036] The filtrate of step 1 was heated to 10℃~40℃ and the flow rate was 8m 3 Under the condition of / h, it pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com