Biological treatment technique for coking waste water

A technology for biological treatment and coking wastewater, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of occupying the effective reaction space of the filter, shortening the hydraulic retention time, and long hydraulic retention time. , to achieve the effect of shortening hydraulic retention time, reducing infrastructure investment, and stabilizing the operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

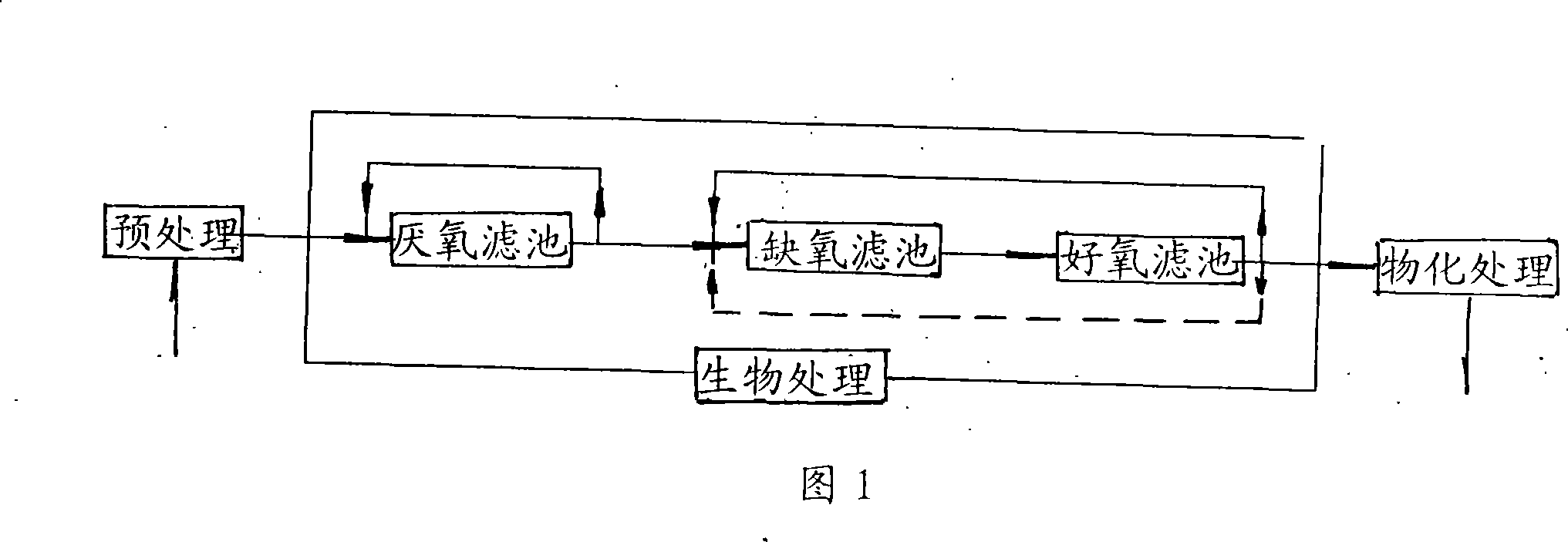

[0022] Example 1, higher concentration coking wastewater: influent water quality is as follows: COD 3300mg / l, ammonia nitrogen 200mg / l, CN -12mg / l, oil 50mg / l, phenol 680mg / l, pH6-9. In Figure 1, after pretreatment (adjustment, oil separation, flotation), the wastewater enters the anaerobic ceramsite filter. The ceramsite filter (reflux ratio 1:1), the effluent of the anoxic ceramsite filter enters the aerobic ceramsite filter, the outlet of the aerobic ceramsite filter enters the post-coagulation treatment section, and part of it flows back into the anoxic ceramsite filter pool (reflux ratio 6:1), there is no secondary sedimentation tank after the aerobic ceramsite filter; anaerobic, anoxic and aerobic ceramsite filters use spherical ceramsite filter material as the film-hanging filler. The ceramsite filter material in the anaerobic ceramsite filter has a particle size of 8-10mm in the lower layer and 6-8mm in the upper layer; in the anoxic ceramsite filter, the particle siz...

Embodiment 2

[0023] Example 2, lower concentration coking wastewater: influent water quality is as follows: COD 1500mg / l, ammonia nitrogen 70mg / l, CN - 8mg / l, oil 50mg / l, phenol 400mg / l, pH6.5-8.5. In Figure 1, after pretreatment (adjustment, oil separation, flotation), the wastewater enters the anaerobic ceramsite filter, and the outlet end of the anaerobic ceramsite filter enters the anoxic filter, and part of it flows back into the anaerobic ceramsite filter (reflux ratio 1:1), the effluent from the anoxic ceramsite filter enters the aerobic filter, the effluent from the aerobic ceramsite filter enters the post-coagulation treatment section, and part of it flows back into the anoxic ceramsite filter (reflux ratio 6:1), there is no secondary sedimentation tank after the aerobic ceramsite filter; anaerobic, anoxic and aerobic ceramsite filters use irregular shaped ceramsite filter material as the hanging film filler. The ceramsite filter material in the anaerobic ceramsite filter has a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com