Advanced treatment method of papermaking wastewater

A technology for advanced treatment of papermaking wastewater, applied in the direction of processing wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high operating cost, high treatment cost, membrane cleaning, etc., and achieve the promotion of chemical oxidation Response, strengthening treatment effect, reducing dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

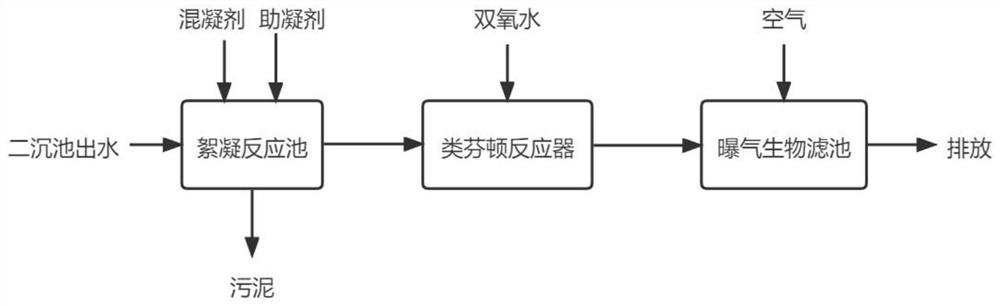

Embodiment 1

[0064] The papermaking wastewater (the effluent from the biochemically treated secondary sedimentation tank, COD: 1200mg / L, TSS: 86mg / L, ammonia nitrogen: 14mg / L, BOD 5 : 180mg / L, chroma: 1600 times, pH: 7.8) into the flocculation reaction tank, add 4g / L polyaluminum ferric chloride and 20mg / L polyacrylamide, quickly mix for 2min, then slowly stir for 5min, at pH Carry out flocculation and precipitation under the condition of 7 for 20min to obtain flocculation supernatant; add hydrogen peroxide (mass concentration of 30%) of 2‰ of the total weight of papermaking wastewater into the flocculation supernatant A Fenton-like reactor equipped with an iron-based Fenton-like catalyst, the volume of the iron-based Fenton-like catalyst is 40% of the volume of the Fenton-like reactor, and the Fenton-like reaction is carried out, and the hydraulic retention time is 25 minutes to obtain a Fenton-like reaction. The reaction effluent; the Fenton-like reaction effluent enters from the bottom ...

Embodiment 2

[0066] The papermaking wastewater (the effluent from the biochemically treated secondary sedimentation tank, COD: 1200mg / L, TSS: 86mg / L, ammonia nitrogen: 14mg / L, BOD 5 : 180mg / L, chroma: 1600 times, pH: 7.8) into the flocculation reaction tank, add 6g / L polyaluminum ferric chloride and 30mg / L polyacrylamide, quickly mix for 2min, then slowly stir for 5min, at pH Carry out flocculation and precipitation under the condition of 7 for 20min to obtain flocculation supernatant; add hydrogen peroxide (mass concentration of 30%) of 2‰ of the total weight of papermaking wastewater into the flocculation supernatant A Fenton-like reactor equipped with an iron-based Fenton-like catalyst, the volume of the iron-based Fenton-like catalyst is 30% of the volume of the Fenton-like reactor, and the Fenton-like reaction is carried out, and the hydraulic retention time is 35min to obtain a Fenton-like reaction. Reaction effluent; the Fenton-like reaction effluent enters from the bottom into the ...

Embodiment 3

[0068] The papermaking wastewater (the effluent from the biochemically treated secondary sedimentation tank, COD: 1200mg / L, TSS: 86mg / L, ammonia nitrogen: 14mg / L, BOD 5 : 180mg / L, chroma: 1600 times, pH: 7.8) into the flocculation reaction tank, add 4g / L polyaluminum ferric bisulfate and 20mg / L polyacrylamide, quickly mix for 2min, then slowly stir for 5min, at pH Carry out flocculation and sedimentation for 20min under the condition of the value of 7 to obtain a flocculation supernatant; add hydrogen peroxide (mass concentration of 30%) of 2‰ of the total weight of papermaking wastewater into the flocculation supernatant. A Fenton-like reactor equipped with an iron-based Fenton-like catalyst, the volume of the iron-based Fenton-like catalyst is 40% of the volume of the Fenton-like reactor, and the Fenton-like reaction is carried out, and the hydraulic retention time is 25min to obtain a Fenton-like reaction. Reaction effluent; the Fenton-like reaction effluent enters from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com