Coking wastewater treatment system and treatment method

A coking wastewater and treatment system technology, applied in the field of water treatment, can solve the problems of low energy consumption, low energy consumption, and less mud production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

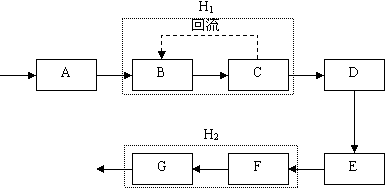

Method used

Image

Examples

Embodiment

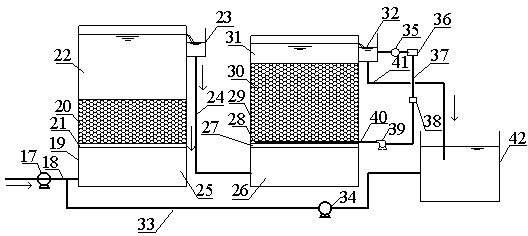

[0040] Example: A newly-built coking wastewater treatment plant with a processing capacity of 200 tons / day, using the treatment system and treatment method of the present invention, after the wastewater is adjusted in water quality, the coking wastewater is pumped into the upflow anaerobic sludge bed using a submersible sewage pump Reactor, followed by anoxic denitrification biological filter / aerobic nitrification biological filter system, multi-stage iron-carbon micro-electrolysis coupled Fenton oxidation bed reactor, aerobic nitrification biological filter / anoxic denitrification biological filter The main design parameters of the tank system are as follows: Influent pH=6.8~8.0, COD cr =1700~2300mg / L, BOD 5 =250~630 mg / L, total nitrogen=400~500mg / L, ammonia nitrogen=280~350 mg / L, SS=220mg / L, color 725 times.

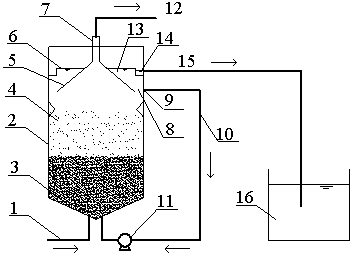

[0041] Upflow anaerobic sludge bed: After the water quality is adjusted, the wastewater first enters the upflow anaerobic sludge bed reactor, hydraulic retention time HRT=2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com