Advanced treatment system of coking wastewater

A technology for coking wastewater and advanced treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Utilization rate, ozone reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

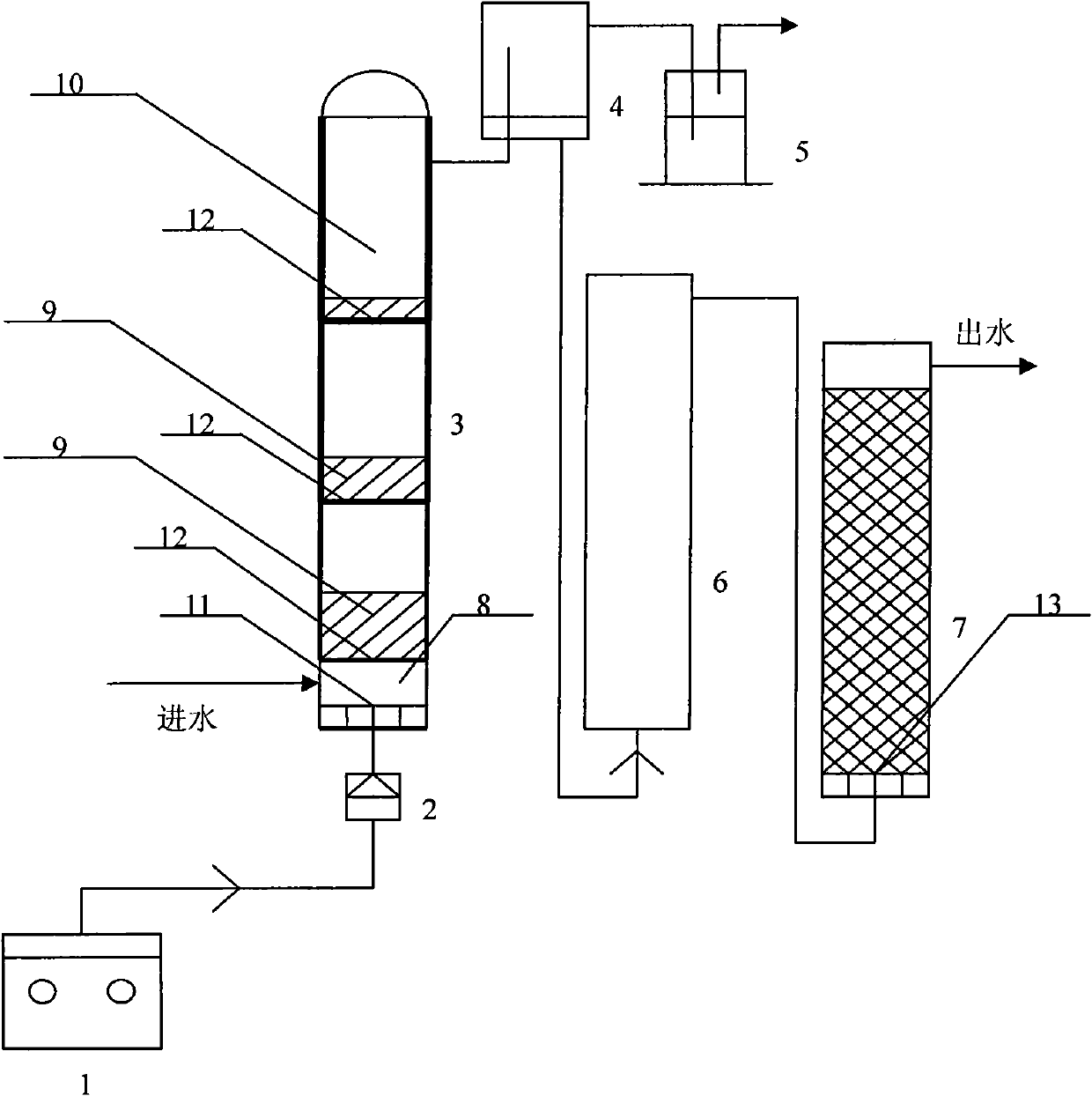

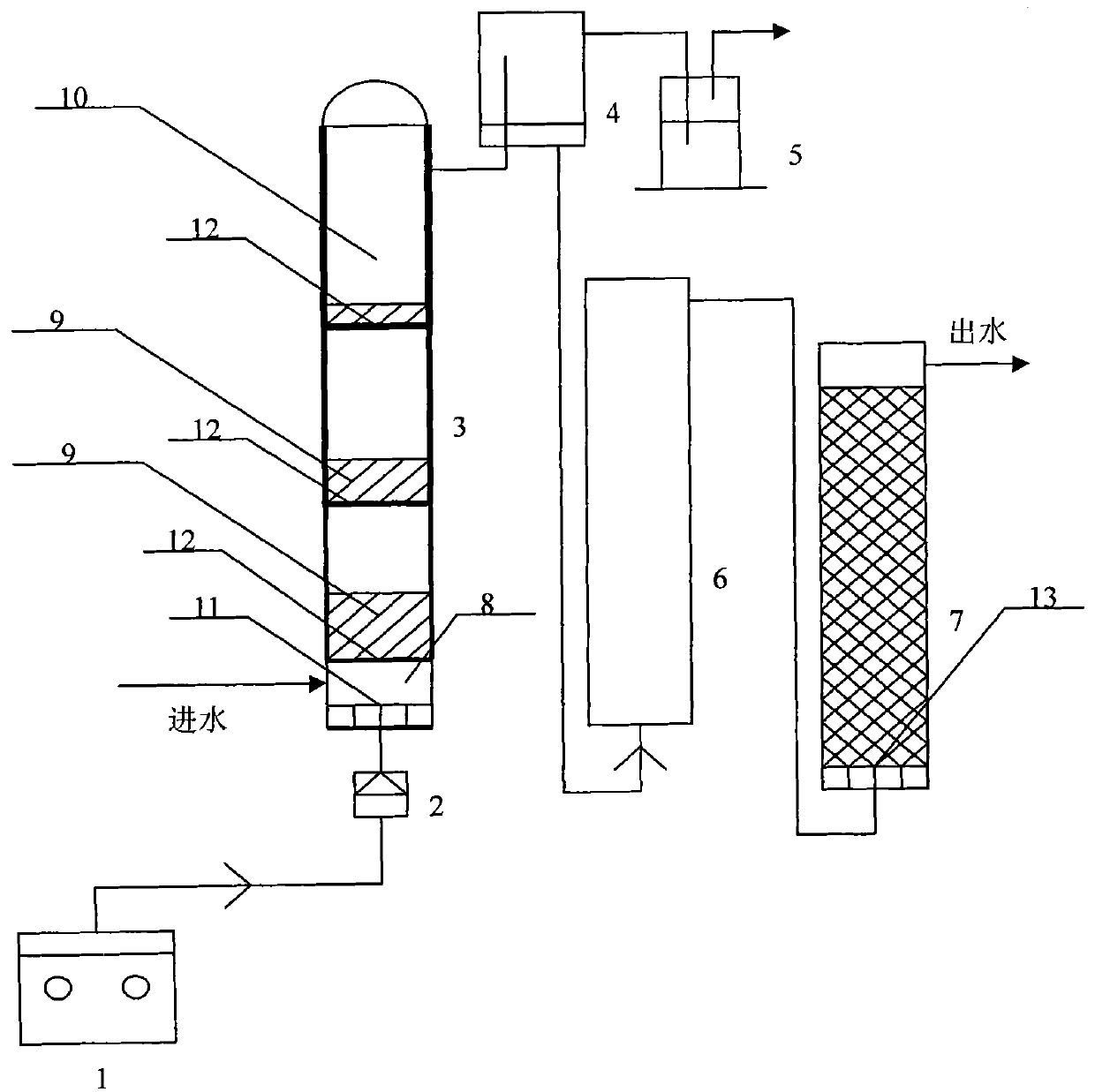

[0018] Coking wastewater advanced treatment system of the present invention, its preferred embodiment is as follows figure 1 As shown, including ozone generator, catalytic ozonation reactor, gas-liquid separation device, buffer column, biological activated carbon reactor, tail gas absorption device;

[0019] The bottom of the catalytic ozonation reactor is provided with an air inlet, which is connected to the gas outlet of the ozone generator;

[0020] The lower side of the catalytic ozonation reactor is provided with a water inlet, and the water inlet introduces the effluent of the coking wastewater biochemical process. Above the water inlet is a three-section repeating structure, and each section of the repeating structure is divided into three subsections. The three sub-sections from bottom to top are the ozone absorption section, the catalyst bed and the catalytic reaction section. The height of the catalyst bed is halved from bottom to top. catalyst and iron oxyhydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com