Method for treating coking wastewater

A technology of coking wastewater and treatment methods, which is applied in the direction of oxidation water/sewage treatment, chemical instruments and methods, flotation water/sewage treatment, etc. It can solve the problems of poor removal of organic matter and difficulty in reaching the secondary discharge standard, etc., and achieve reduction Biological oxygen demand, improving the effect of hydrolysis and acidification, and promoting the effect of electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

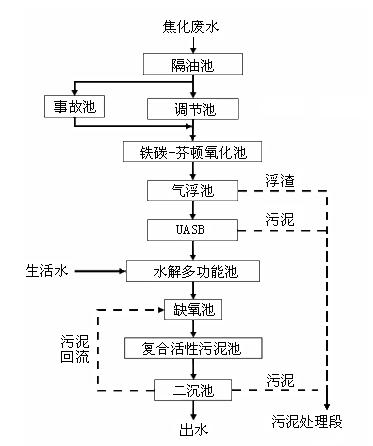

[0012] Specific embodiment one: the processing method of coking wastewater in the present embodiment is as follows: one, Put the coking wastewater into the grease trap for precipitation for 1 to 4 hours; 2. The effluent treated in step 1 enters the regulating tank to adjust the pH value to 4 to 5; 3. The effluent treated in step 2 enters the tank equipped with iron filings and activated carbon In the iron-carbon-Fenton oxidation pool of the mixture, then add hydrogen peroxide until the concentration of hydrogen peroxide is 0.10L / m 3 ~0.50L / m 3 , adjust the pH value to 4-5, and the hydraulic retention time is 2.0h-3.5h; 4. After the effluent treated in step 3 enters the air flotation tank, the hydraulic retention time is 1h-4h; 5. Remove the scum produced in the air flotation tank Introduced into the sludge treatment section, the effluent from the air flotation tank enters the upflow anaerobic sludge bed reactor, and the anaerobic sludge concentration in the reactor is 15kg / m ...

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentration of hydrogen peroxide after adding hydrogen peroxide in step three is 0.20L / m 3 ~0.40L / m 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the concentration of hydrogen peroxide after adding hydrogen peroxide in step three is 0.30L / m 3 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com