Deep purification method of coking wastewater based on advanced ozone oxidation

A technology for coking wastewater and advanced oxidation is applied in the advanced treatment of effluent from biochemical treatment facilities in coking plants and in the field of coking wastewater treatment, and can solve the problems of good effect, complex process steps and unsatisfactory oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

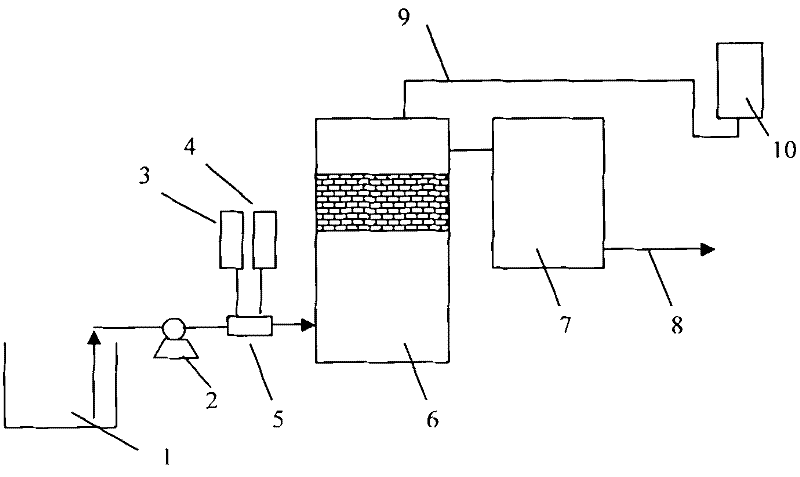

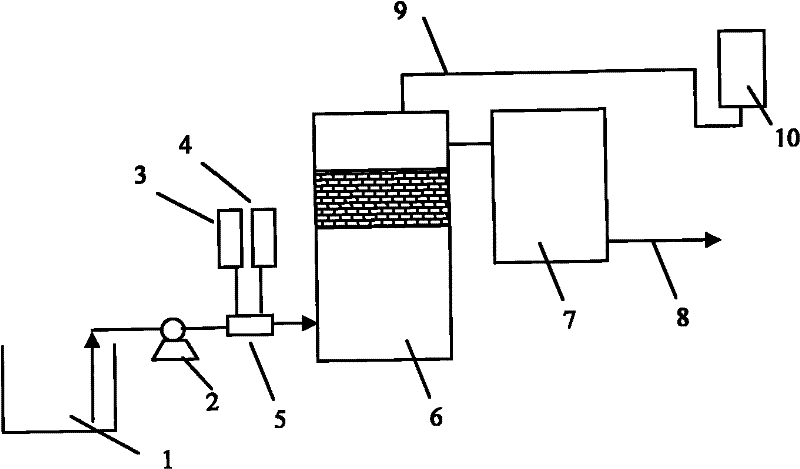

Method used

Image

Examples

Embodiment 1

[0030] Send the biochemically treated coking wastewater into the regulating pool 1 with a flow rate of 1m 3 / h, adjust the pH value of the wastewater to 8 with quicklime in the adjustment tank 1, turn on the water pump 2, pump the wastewater into the oxidation reactor 6, and add ozone-containing gas to the oxidation reactor 6, with a flow rate of 2m 3 / h, O in gas 3 The concentration is 70mg / L, that is, adding 140mg of ozone per liter of wastewater; at the same time adding 30% hydrogen peroxide, H 2 o 2 with O 3 The molar ratio of the added amount is 0.5; 53L Al is housed in the oxidation reactor 6 2 o 3 load Fe 2 o 3 The solid heterogeneous catalyst, the volume ratio of the oxidation reactor 6 to the volume of the solid heterogeneous catalyst is 1:3, and the hydraulic retention time is 5 minutes.

[0031] The oxidized waste water is filtered through the filter 7 and discharged, and the effluent COD reaches the national first-class discharge standard before being dischar...

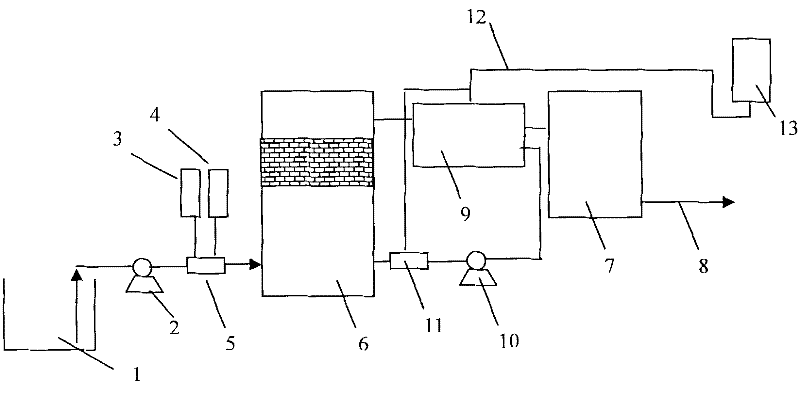

Embodiment 2

[0033] Send the biochemically treated coking wastewater into the regulating tank 1 with a flow rate of 5 L / min, adjust the pH value of the wastewater to 12 with NaOH in the regulating tank, turn on the water pump 2, and pump the wastewater from the regulating tank 1 into the mixing jet 5, Open ozone generator 4 simultaneously, regulate gas flow to be 20L / min, make the gas flow of gas flow of gas generator 4 outlets and flow through the ratio of the waste water flow in mixing jet 5 be 4: 1, ozone concentration is 100mg / min in the gas. L; Open the hydrogen peroxide tank 3 at the same time, add the hydrogen peroxide with a concentration of 27%, H 2 o 2 with O 3 The molar ratio of the added amount was 1.4. Waste water, ozone, hydrogen peroxide enter in oxidation reactor 6, and hydraulic retention time is 20 minutes, and 27L TiO2 is housed in oxidation reactor 6 2 load MnO x The solid heterogeneous catalyst, the volume ratio of the oxidation reactor 6 to the volume of the solid...

Embodiment 3

[0036] Send the biochemically treated coking wastewater into the regulating tank 1 with a flow rate of 10L / min, adjust the pH value of the wastewater to 10 with NaOH in the regulating tank, turn on the water pump 2, and pump the wastewater from the regulating tank 1 into the mixing jet 5, and at the same time Open the ozone generator 4, adjust the gas flow to be 30L / min, so that the ratio of the gas flow at the outlet of the odor generator 4 and the waste water flow through the mixing jet 5 is 3: 1, and the ozone concentration in the gas is 80mg / L ; Open hydrogen peroxide tank 3 at the same time, adding concentration is 27% hydrogen peroxide, H 2 o 2 with O 3 The molar ratio of the added amount was 1. Waste water, ozone, hydrogen peroxide enter in the oxidation reactor 6, and the hydraulic retention time is 10 minutes, and 40L Al is housed in the oxidation reactor 6 2 o 3 load Fe 2 o 3 The solid heterogeneous catalyst, the volume ratio of the oxidation reactor 6 to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com