Semi-coke wastewater treatment method

A treatment method, technology of semi-coke wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of aerobic activated sludge method that is difficult to directly treat and degrade Problems such as high organic matter content and damage to the biological treatment system have achieved the effects of low construction costs, reliable operation up to the standard, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

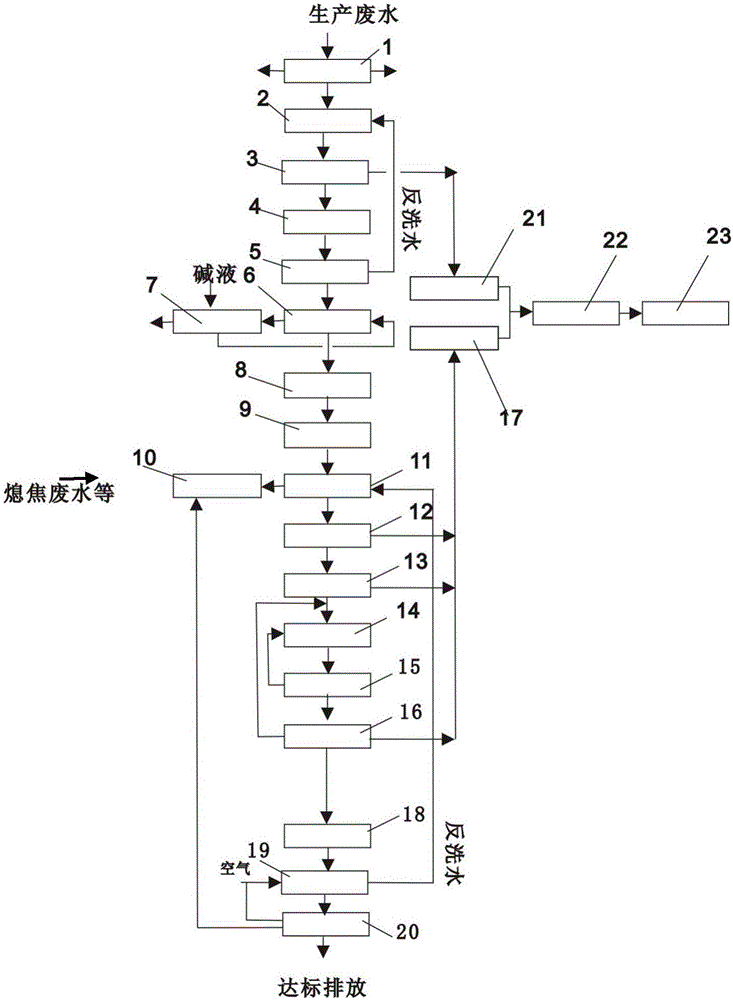

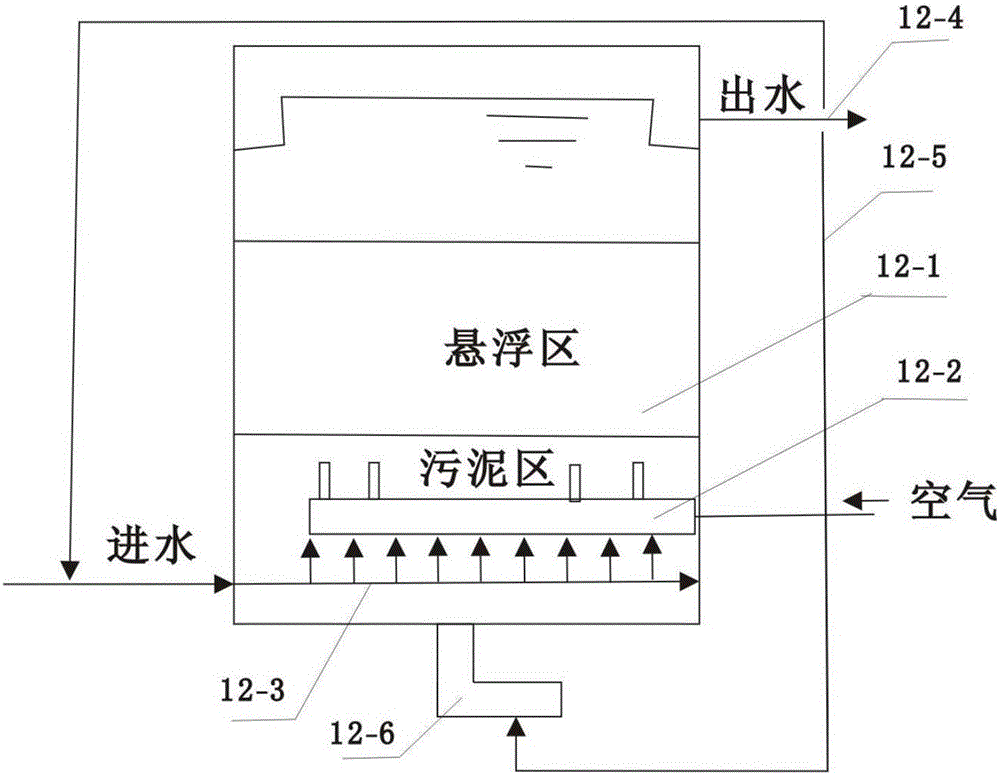

Method used

Image

Examples

Embodiment 1

[0036] The waste water treated by the present invention is semi-coke waste water, which is the waste water produced in the coal semi-coke products and coke quenching process. In the present invention, waste water other than coke quenching waste water, coal-fired pipeline condensate water, gas water sealing water and laboratory test water in the production process is called production waste water, excluding domestic waste water. The pool is mixed with coke quenching wastewater, coal-fired pipeline condensate, gas water seal water and laboratory test water.

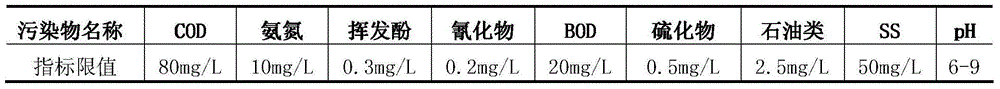

[0037] Emission Standards:

[0038] According to the technical requirements of the bidding documents of this project, the semi-coke production wastewater implements the "Coking Chemical Industry Pollutant Discharge Standard" (GB16171-2012), and the main control water quality indicators and discharge concentration limits of the discharged wastewater should meet the requirements of Table 1:

[0039] Table 1 List of main cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com