Coking wastewater biological denitrificaion treatment process

A technology for coking wastewater and biological denitrification, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. and other problems, to achieve the effect of stable operation effect, low operation cost and high denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

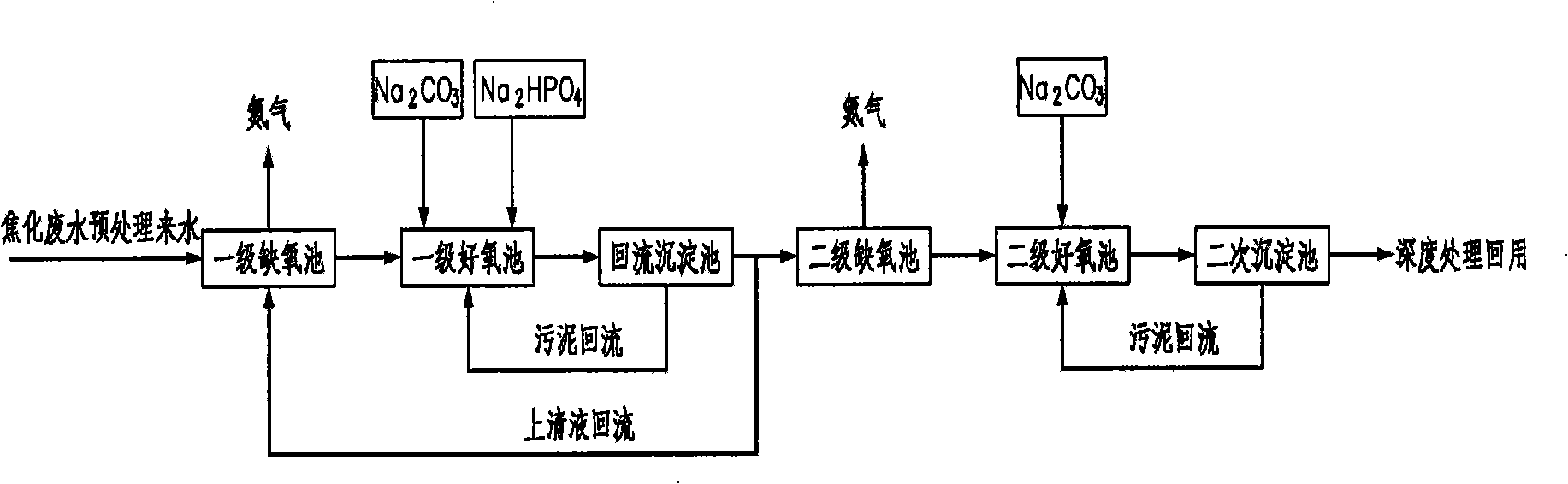

[0026] Using "A / O / A / O (Anoxic / Aerobic / Anoxic / Aerobic)" as the core biological denitrification treatment process for coking wastewater, the specific implementation methods are as follows:

[0027]The pretreated coking waste water enters the bottom water distribution system of the primary anoxic tank after being lifted, and the supernatant of the reflux sedimentation tank (reflux ratio 3:1) also returns to the water distribution system. The first-level anoxic pool is vertical flow, and the water distribution system adopts a large-resistance water distribution method, and the pool is covered with fixed elastic biological fillers. Under anoxic conditions, the anaerobic denitrifying bacteria in the first-stage anoxic tank take the organic matter (COD Cr ) as the carbon source, with the oxygen of nitrite nitrogen and part of the nitrate nitrogen in the reflux supernatant as the electric acceptor, carry out respiration and life activities, and reduce it into nitrogen (N 2 ) escapes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com