Technique for processing coking wastewater or organic wastewater by supercritical water oxidization technique

A technology for supercritical water oxidation and coking wastewater, which is applied in the fields of oxidized water/sewage treatment, water/sewage treatment, degassed water/sewage treatment, etc. To achieve the effect of accelerated reaction time, shortened process flow and huge environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

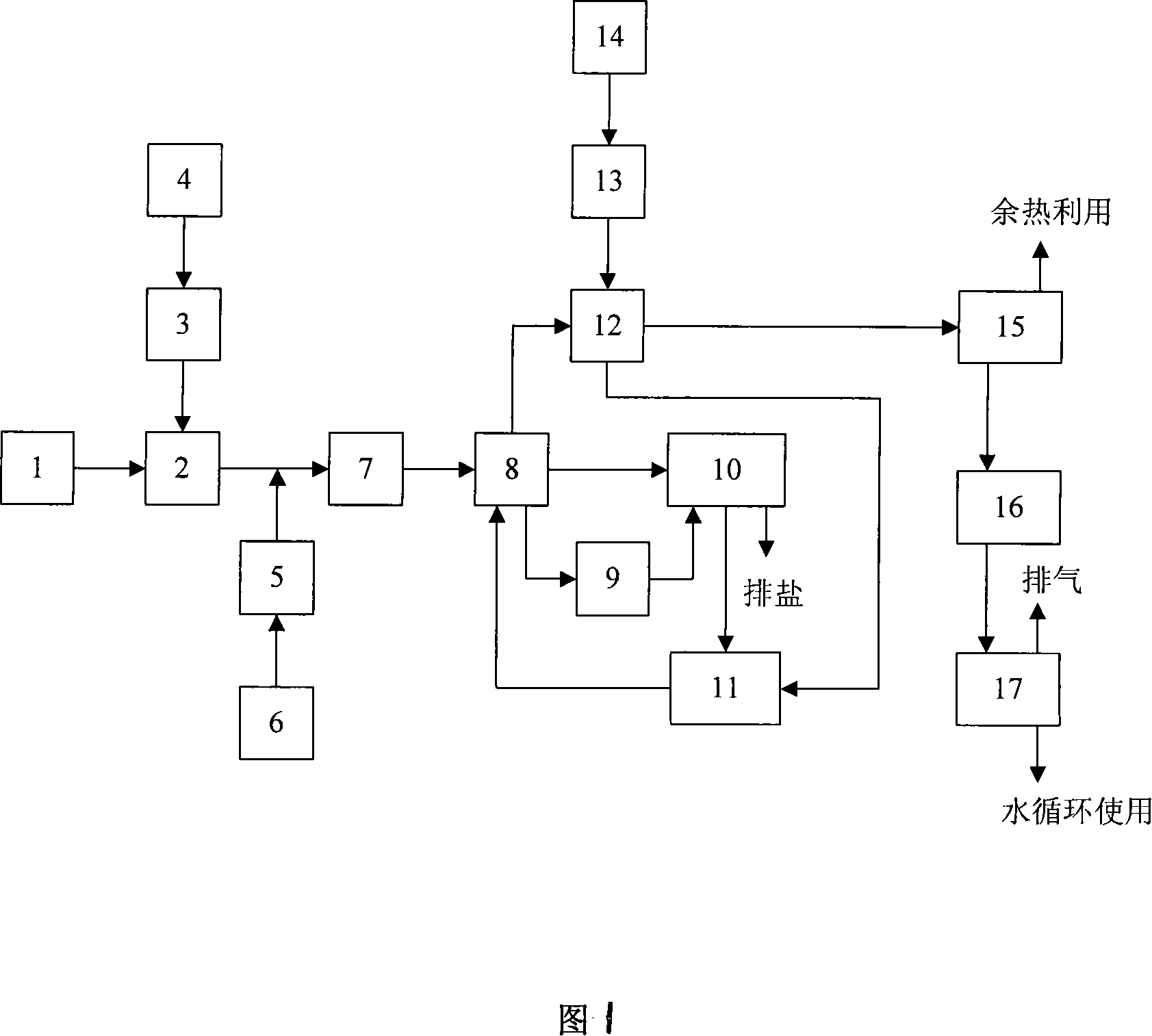

[0024] Below in conjunction with accompanying drawing (Fig. 1) the present invention is described.

[0025] The supercritical water oxidation technology of the present invention is used to treat coking wastewater or organic wastewater. The supercritical water oxidation technology is used to treat coking wastewater or organic wastewater. The organic pollutants and oxidants in the wastewater are all dissolved in water, and the oxidation reaction is carried out in a homogeneous phase. In a short reaction time, organic pollutants are quickly oxidized and decomposed, and the insoluble properties of supercritical inorganic substances are used to remove salt in water. The present invention includes pretreatment equipment for coking wastewater or organic wastewater, using high-efficiency inclined plate sedimentation tanks to remove solid particles in wastewater, and then using high-pressure pumps to transport them to energy-saving heat exchangers for heating, initially using supercriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com