Coking wastewater comprehensive treatment method and system thereof

A technology for coking wastewater and comprehensive treatment, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low ammonia nitrogen and COD removal rate, high operating cost and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

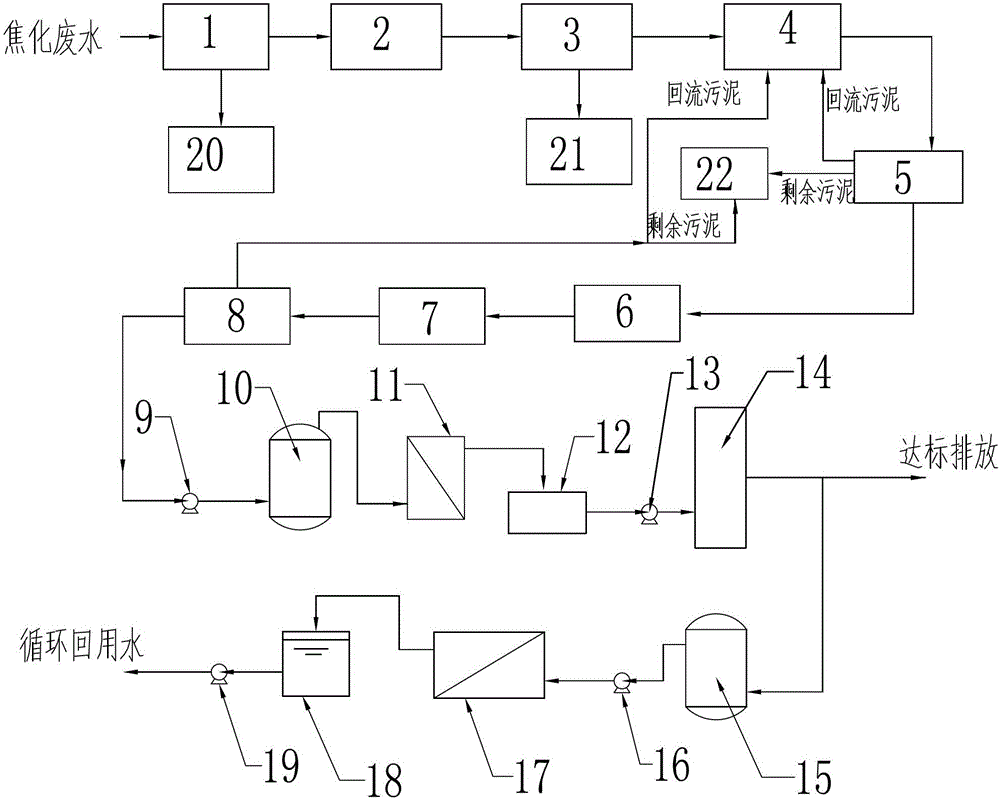

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 Shown is coking wastewater comprehensive treatment method of the present invention, concrete operation is as follows:

[0021] The coking wastewater enters the degreasing tank 1 to remove tar, and the tar is discharged into the oil storage tank 20 for storage. The effluent of oil removal tank 1 flows into the adjustment tank 2, and the adjustment tank 2 adds oxidant to remove phenols, and adds NaOH or Ca(OH) 2 Adjust the pH to 6-9, and then flow the wastewater into the air flotation tank 3, remove the substances with a density lower than water through the air flotation tank 3, add a flocculant to flocculate and precipitate the suspended matter, remove heavy metals and cyanide, etc. The scum is automatically discharged into the slag storage tank 21. After pretreatment, the water quality basically meets the requirements of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com