Method for preparing ozone catalytic oxidation catalyst for treating coking wastewater

A technology for ozone catalytic oxidation and coking wastewater, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Adsorption, catalytic performance and other issues, to achieve the effect of simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

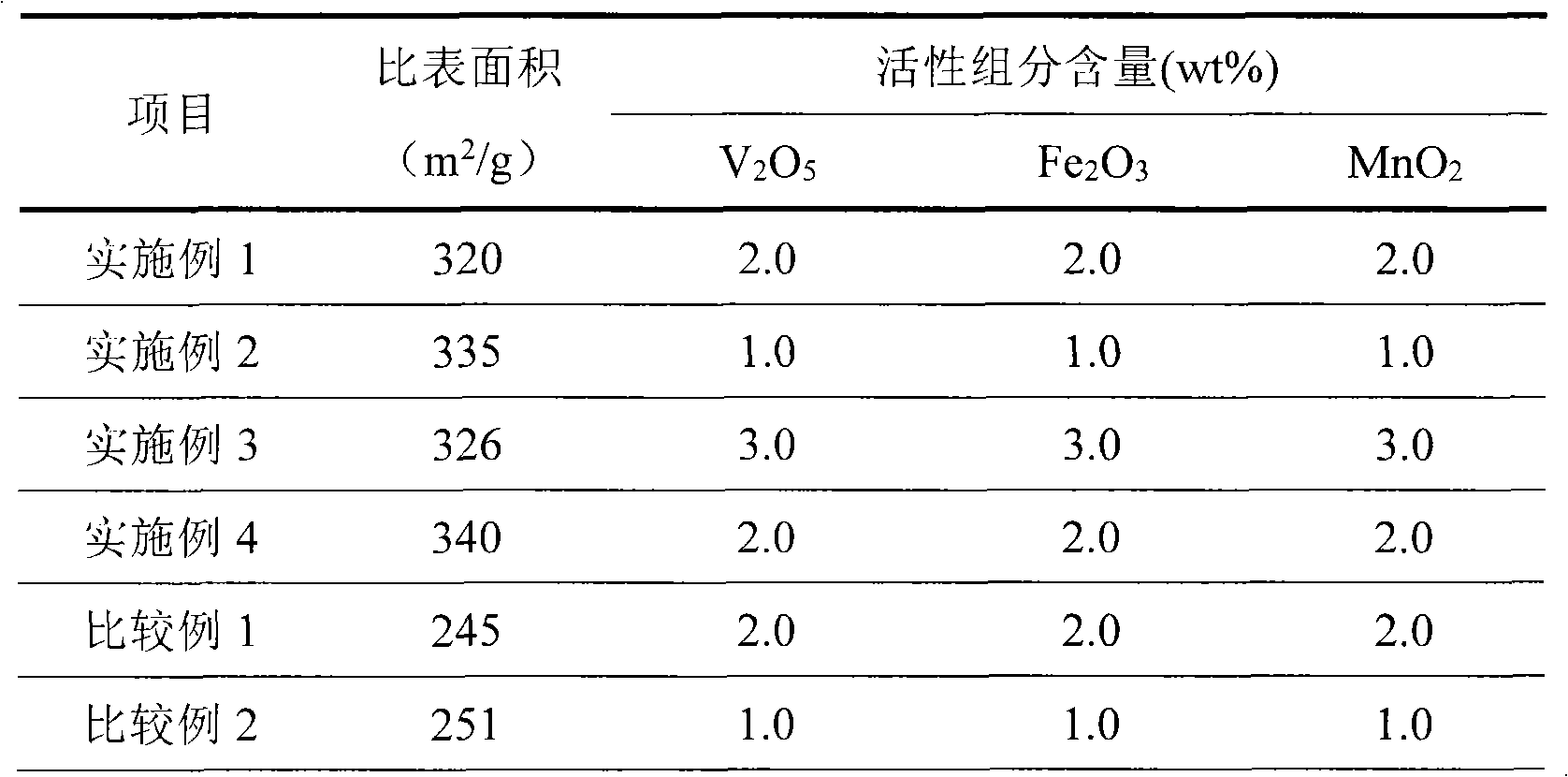

[0025] Take 129gNH 4 VO 3 Solid, add 129g oxalic acid, add 1.5kg water to dissolve into a solution, slowly add 505gFe(NO 3 ) 3 9H 2 O solid, 412g content is 50% Mn(NO 3 ) 2 solution, dissolved to obtain a solution. Get 5.4kg of amorphous alumina (produced by CNOOC Tianjin Chemical Research and Design Institute, trade name AKF101), spray into the prepared solution and carry out rolling granulation until the particle size is 3mm, stop when the particle size is 3mm, maintain at 101°C for 20hr, and dry at 110°C for 4hr. Calcined at 550°C for 3 hours to obtain an ozone catalytic oxidation catalyst. The specific surface area and active component content of the finished catalyst are listed in Table 1.

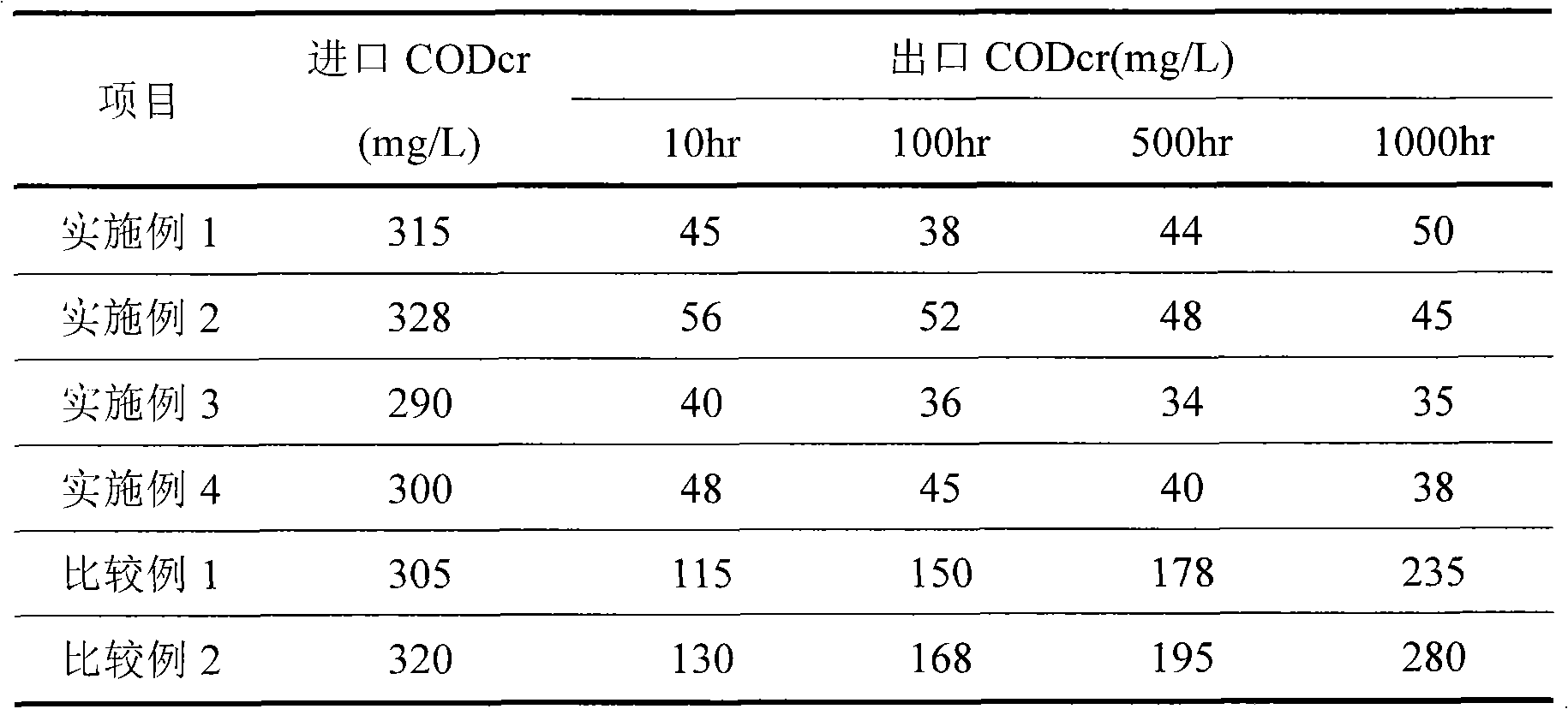

[0026] Catalyst performance evaluation is achieved by the following devices:

[0027] Reactor: fixed bed reactor

[0028] Catalyst loading volume: 100ml, filling aspect ratio is 4:1

[0029] Temperature: room temperature

[0030] Residence time: 20min

[0031] Device runni...

Embodiment 2

[0036] The configuration of the active component solution is selected from ammonium metavanadate, iron nitrate, and manganese nitrate equivalent to 1.0% of the mass of the amorphous alumina carrier, and the rest of the catalyst preparation steps are the same as in Example 1. The specific surface area and active component content of the finished catalyst are listed in Table 1.

[0037] The catalyst was tested as in Example 1, and the evaluation results of the catalyst are shown in Table 2.

Embodiment 3

[0039] The configuration of the active component solution is ammonium metavanadate, iron nitrate and manganese nitrate equivalent to 3.0% of the mass of the amorphous alumina carrier, and the rest of the catalyst preparation steps are the same as in Example 1. The specific surface area and active component content of the finished catalyst are listed in Table 1.

[0040] The catalyst was tested as in Example 1, and the evaluation results of the catalyst are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com