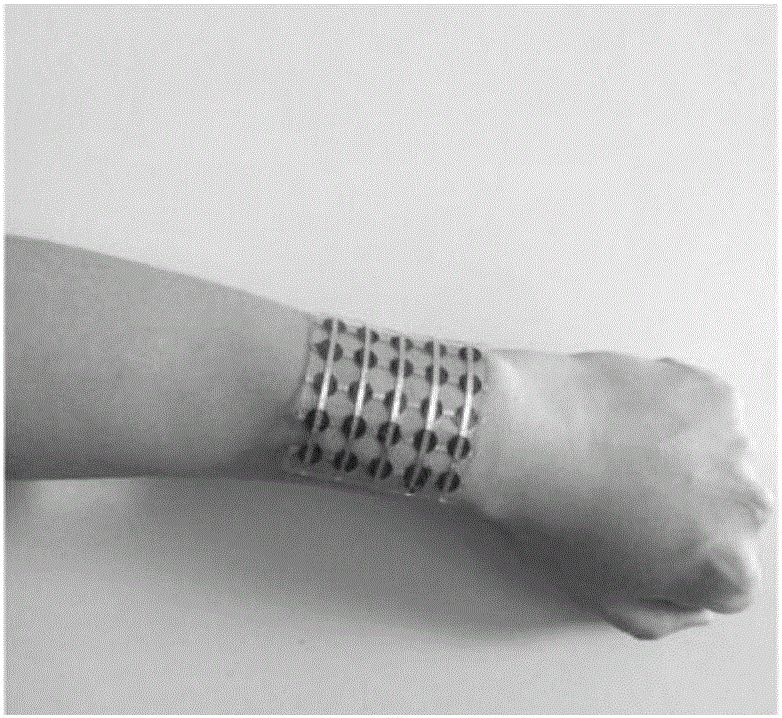

Development of flexible resistance type pressure transducer capable of being applied to human body pulse detection

A resistive pressure and sensor technology, applied in sensors, applications, diagnostic recording/measurement, etc., can solve the problems of large hysteresis, poor stability, low sensitivity, etc., and achieve the effects of low cost, simple and environmentally friendly preparation method, and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of polyvinylidene fluoride micro-nano fibers: First, 2 grams of polyvinylidene fluoride was dissolved in 4 grams of acetone and 4 grams of N-N dimethylformamide mixed solution, stirred at room temperature for 4 hours until the solution was uniform and transparent. After that, take 1 ml of the mixed solution into a 5 ml disposable plastic needle to start electrospinning. The spinning parameters are: voltage 10 kV, receiving plate distance 10 cm, spinning time 30 seconds. In order that the graphene can be completely coated on the surface of the nanofibers, the collection device used is a hollow stainless steel mesh.

[0021] 2. Preparation of graphene-coated polyvinylidene fluoride nanofibers: first, take 0.75 milliliters of graphene oxide solution and pour it into 29.25 milliliters of deionized water, after stirring for half an hour, the polyvinylidene fluoride nanofiber membrane is suspended in the above solution After stirring at room temperature for 2 ...

Embodiment 2

[0026] 1. Increase the spinning collection time of polyvinylidene fluoride micro-nano fibers to 60s;

[0027] 2. The concentration of the graphene oxide solution is increased to 2 times of the original;

[0028] 3. The thickness of the PDMS substrate is doubled;

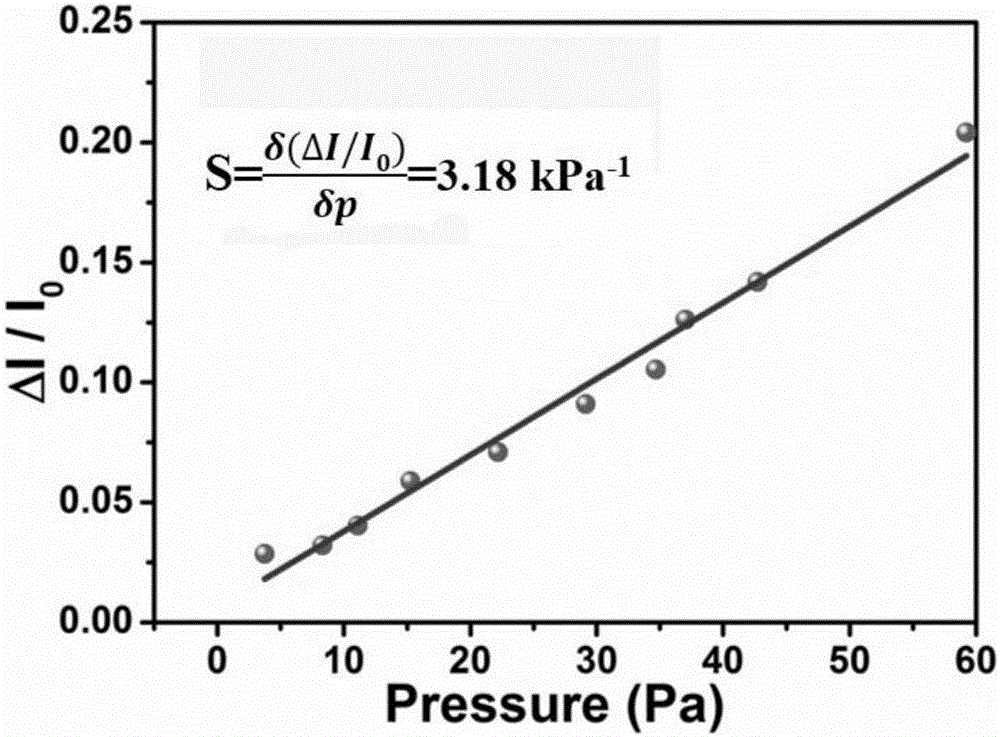

[0029] Other experimental parameters and device manufacturing methods are the same as in Example 1, and the pressure performance of the test sensor and the ability to detect human pulse are different from those in Example 1. It is found that the longer the spinning collection time of polymer micro-nanofibers, the greater the thickness of the fiber film, or increasing the concentration of graphene oxide, the more layers of graphene deposited, which will lead to an increase in the conductivity of the device, but its The sensitivity will decrease, thereby reducing the ability to detect the human pulse; the increase in the thickness of the PDMS film will reduce the device's sensitivity to pressure deformation, thereby h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com