Preparation of silicon dioxide / polyvinylidene fluoride composite nano fiber film

A composite nanofiber, polyvinylidene fluoride technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of difficult shape control, high raw material cost, strict equipment requirements, etc., to achieve good photoelectric performance, reaction Fast, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

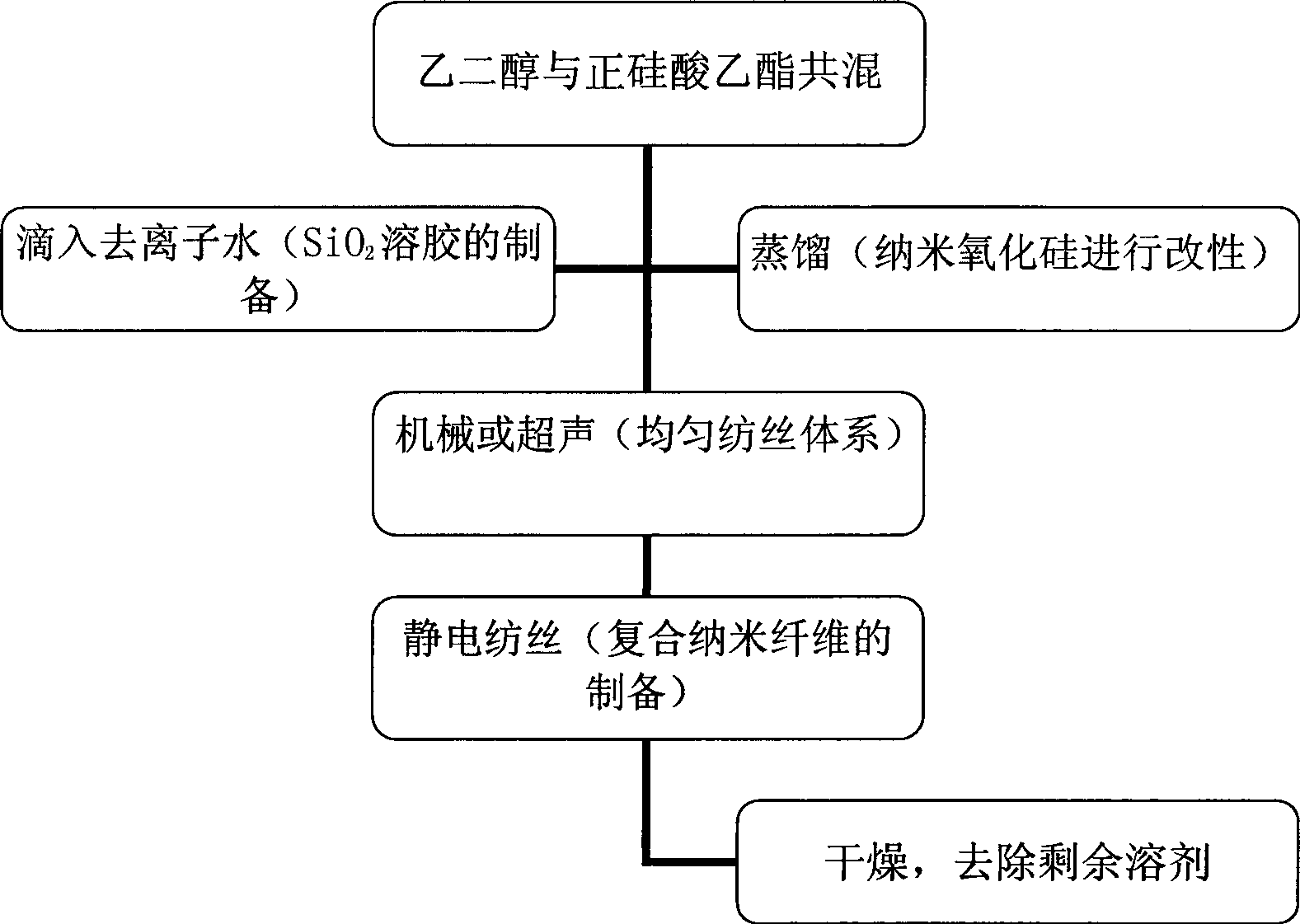

Method used

Image

Examples

Embodiment 1

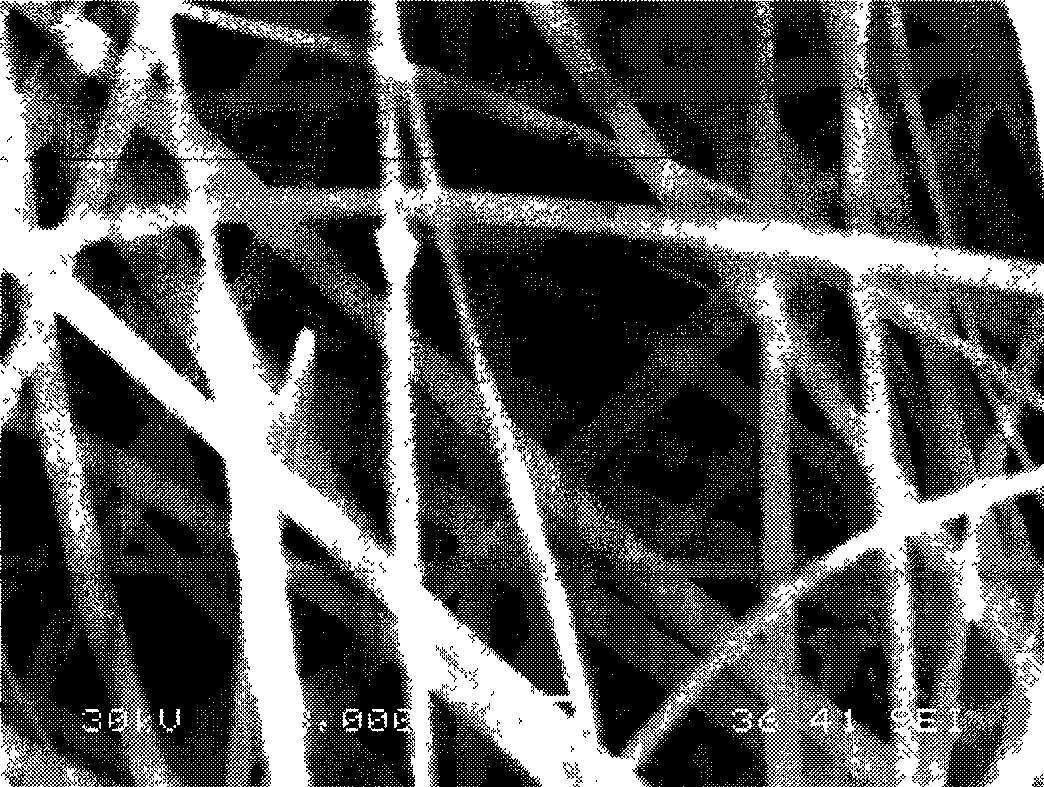

[0017] Add 20ml of ethylene glycol and 2ml of tetraethylorthosilicate into a three-necked round-bottomed flask, heat in a water bath to 70°C, add 1ml of deionized water drop by drop using a pipette, and react for 2 hours under normal pressure. Gradually lower the temperature to 50°C, connect to a distillation device, distill off part of the water generated by the reaction, and promote the dehydration reaction between ethylene glycol and the hydroxyl groups on the surface of the silica. The reaction time is 1 hour; the silica sol system generated by the reaction is placed in into the extractor shown, using acetone as the extracting solution, heated to 65°C in a water bath, and obtained pure modified nano-silicon dioxide after 5 hours; mixed 25.7ml of acetone, 2g of PVDF and 0.2g of silicon dioxide into the Erlenmeyer flask, Use a magnetic stirrer to stir for 2 hours to obtain a uniformly mixed PVDF / silica / acetone system, put it into a self-made spinning equipment, and under the ...

example 2

[0019] Add 20ml of ethylene glycol and 2ml of tetraethyl orthosilicate into a three-necked round-bottomed flask, heat it in a water bath to 70°C, add 1.5ml of deionized water drop by drop using a pipette, raise the temperature to 90°C, and put it under normal pressure React for 1.5 hours. Gradually lower the temperature to 50°C, connect to a distillation device, distill off part of the water generated by the reaction, and promote the dehydration reaction between ethylene glycol and the hydroxyl groups on the surface of the silica. The reaction time is 1 hour; the silica sol system generated by the reaction is placed in into the extractor shown, using acetone as the extracting solution, heated to 65°C in a water bath, and obtained pure modified nano-silica after 5 hours; mixed 24.4ml of acetone, 3g of PVDF and 0.2g of silicon dioxide into the Erlenmeyer flask, Use ultrasonic vibration for 1 hour to obtain a uniformly mixed PVDF / silica / acetone system, put it into self-made spinn...

example 3

[0021] Add 20ml of ethylene glycol and 2.5ml of tetraethyl orthosilicate into a three-neck round bottom flask, heat it in an oil bath to 70°C, add 2ml of deionized water drop by drop using a pipette, raise the temperature to 110°C, and press The reaction was carried out for 0.5 hours. Gradually lower the temperature to 50°C, connect to a distillation device, distill off part of the water generated by the reaction, and promote the dehydration reaction between ethylene glycol and the hydroxyl groups on the surface of the silica. The reaction time is 1 hour; the silica sol system generated by the reaction is placed in into the extractor shown, using acetone as the extracting solution, heated to 65°C in a water bath, and obtained pure modified nano-silicon dioxide after 5 hours; mixed 23.2ml of acetone, 4g of PVDF and 0.2g of silicon dioxide into the Erlenmeyer flask, Use a magnetic stirrer to stir for 1 hour, and ultrasonically oscillate for 15 minutes to obtain a uniformly mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com