Radiation refrigeration fiber, preparation method thereof and application of fiber

A radiation refrigeration and fiber technology, applied in the textile field, can solve the problems of poor stability of textile cooling function, complicated process, high cost, etc., and achieve the effect of stable radiation refrigeration effect, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

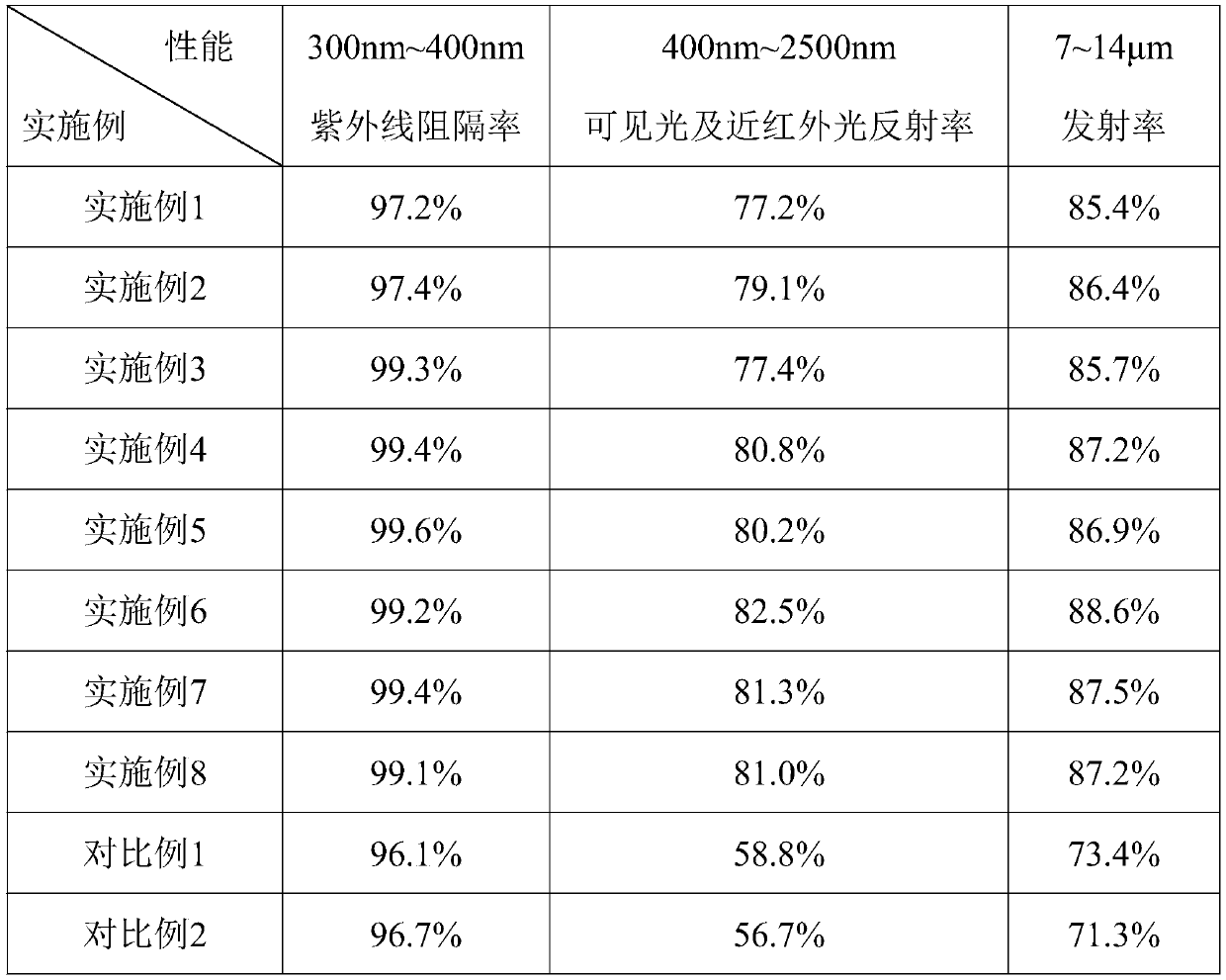

Examples

preparation example Construction

[0040] In the current fiber preparation method, melt spinning has the advantages of simple process, no solvent, high spinning rate, and high fiber strength. Therefore, the present invention also provides a method for preparing the above-mentioned radiation refrigeration fiber, include:

[0041] S1, mixing the material of the matrix with the functional filler to obtain a mixture, the mass percentage of the functional filler in the mixture is 1%-17%;

[0042] S2, the mixture is melted and spun to obtain radiation cooling fibers, the linear density of the radiation cooling fibers is 0.3dtex-10dtex, the radiation cooling fibers can reflect visible light and near-infrared light, and pass through the atmosphere in the form of infrared radiation Windows emit heat.

[0043] In step S1, the intrinsic viscosity of the material of the matrix is 0.5dL / g-1dL / g, so as to ensure that the mixture has an appropriate viscosity when melting, which is convenient for processing.

[0044] Furth...

Embodiment 1

[0059] Provide PVDF with an intrinsic viscosity of 0.5dL / g and CaCO with a particle size of 10μm 3 Functional filler, 98% by mass of PVDF material and 2% by mass of CaCO 3 The functional fillers are mixed to obtain a mixture. Then the mixture was melted and spun to obtain radiant cooling fibers, wherein the spinning temperature was 200° C. and the spinning speed was 800 m / min.

[0060] The radiation cooling fiber obtained in this example has a linear density of 0.3 dtex, a breaking strength of 7 cN / tex, a breaking elongation of 8%, and an initial modulus of 22 GPa. The linear density of the radiation cooling yarn made from the radiation cooling fiber of this embodiment is 1dtex.

Embodiment 2

[0062] Provide PET with intrinsic viscosity of 1dL / g and jade powder functional filler with a particle size of 10μm, disperse 97% by mass of PET material, 2% by mass of jade powder functional filler, and 1% by mass of stearic acid mixture to obtain a mixture. Then the mixture is melted and spun to obtain radiant cooling fibers, wherein the spinning temperature is 300° C. and the spinning speed is 1000 m / min.

[0063] The radiation cooling fiber obtained in this example has a linear density of 0.3 dtex, a breaking strength of 23 cN / tex, a breaking elongation of 28%, and an initial modulus of 15 GPa. The linear density of the radiation cooling yarn made from the radiation cooling fiber of this embodiment is 1dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com