Radiation refrigeration fiber membrane and preparation method and application thereof

A technology of radiation refrigeration and fiber membrane, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc. It can solve the problems of poor refrigeration performance, complicated preparation method, poor air permeability, etc., and achieve good radiation refrigeration effect and preparation method Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

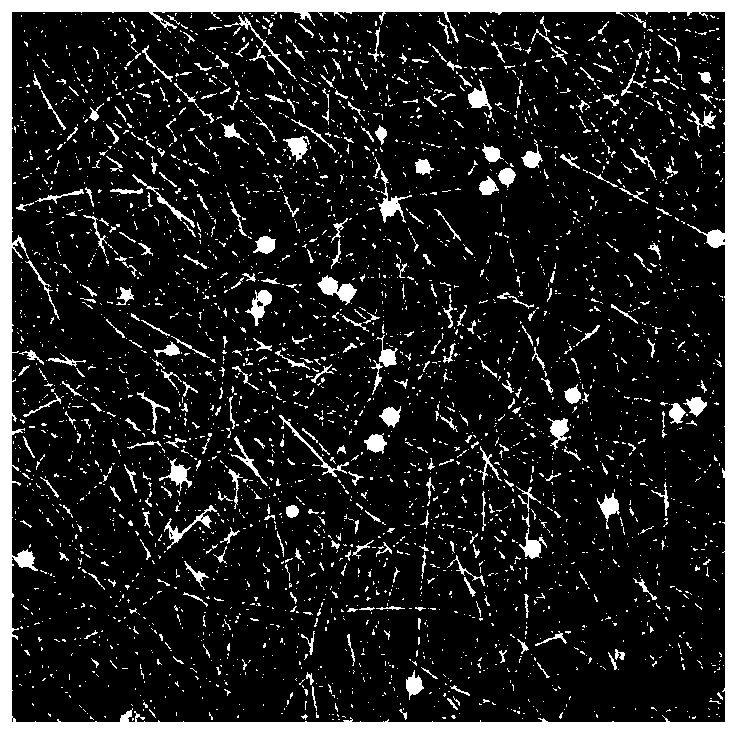

Embodiment 1

[0036] At room temperature, measure 2ml of tetraethyl silicate (reagent grade, 98%, Aladdin Reagent (Shanghai) Co., Ltd.) and disperse it in 35ml of absolute ethanol, stir well to form solution 1; measure 65ml of absolute ethanol (premium grade Pure GR 500ml, Sinopharm Chemical Reagent Co., Ltd.), 10ml deionized water and 9ml ammonia water (superior pure GR 500ml, Sinopharm Chemical Reagent Co., Ltd.), mixed evenly to obtain solution 2; solution 1 was mixed at a rate of 12ml / h Drop into the solution 2, and then react for 5 hours after the dropwise addition, using this The method prepared uniformly dispersed SiO with an average particle size of about 1.3 μm 2 The microspheres are ready for use; take 1.5g PA6 slices (181110-500G, Sigma-Aldrich (Shanghai) Trading Co., Ltd.) and dissolve them in 8.5g formic acid (analytical pure AR 500ml, 98%, Sinopharm Chemical Reagent Co., Ltd.), Stir evenly to completely dissolve PA6 to obtain 15% PA6 solution, then weigh 0.15g of SiO prepare...

Embodiment 2

[0040] 0.45g SiO 2 The microspheres were added to the PA6 solution to obtain SiO 2 Dosage is the mixed dispersion liquid of 30%, all the other are identical with embodiment 1, obtain PA6 / SiO 2 The radiative cooling fiber membrane is ready for use, with a thickness of 20 μm.

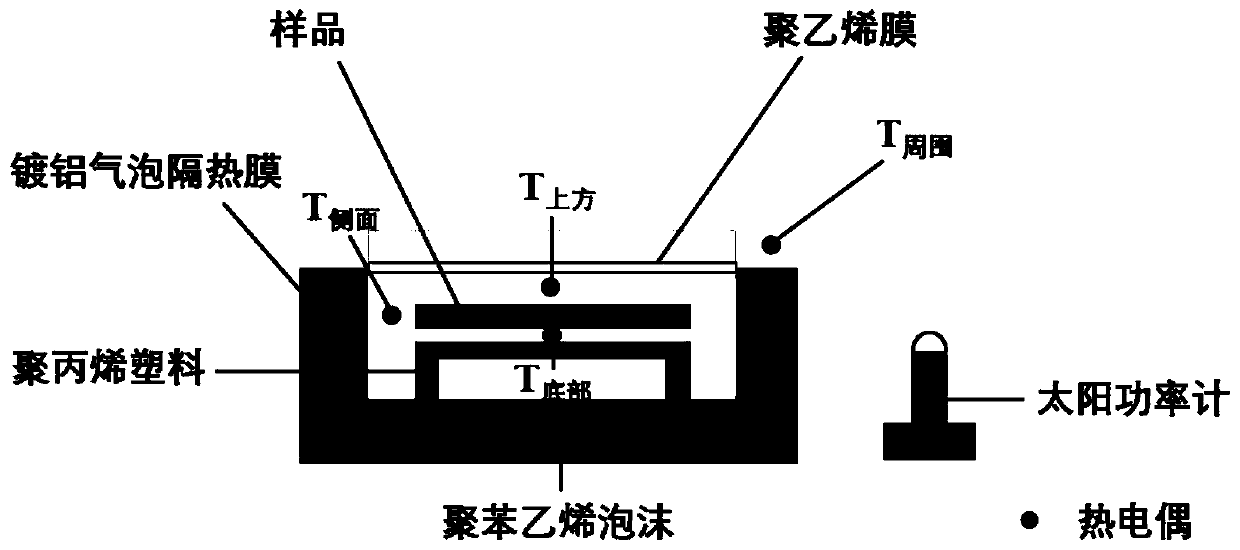

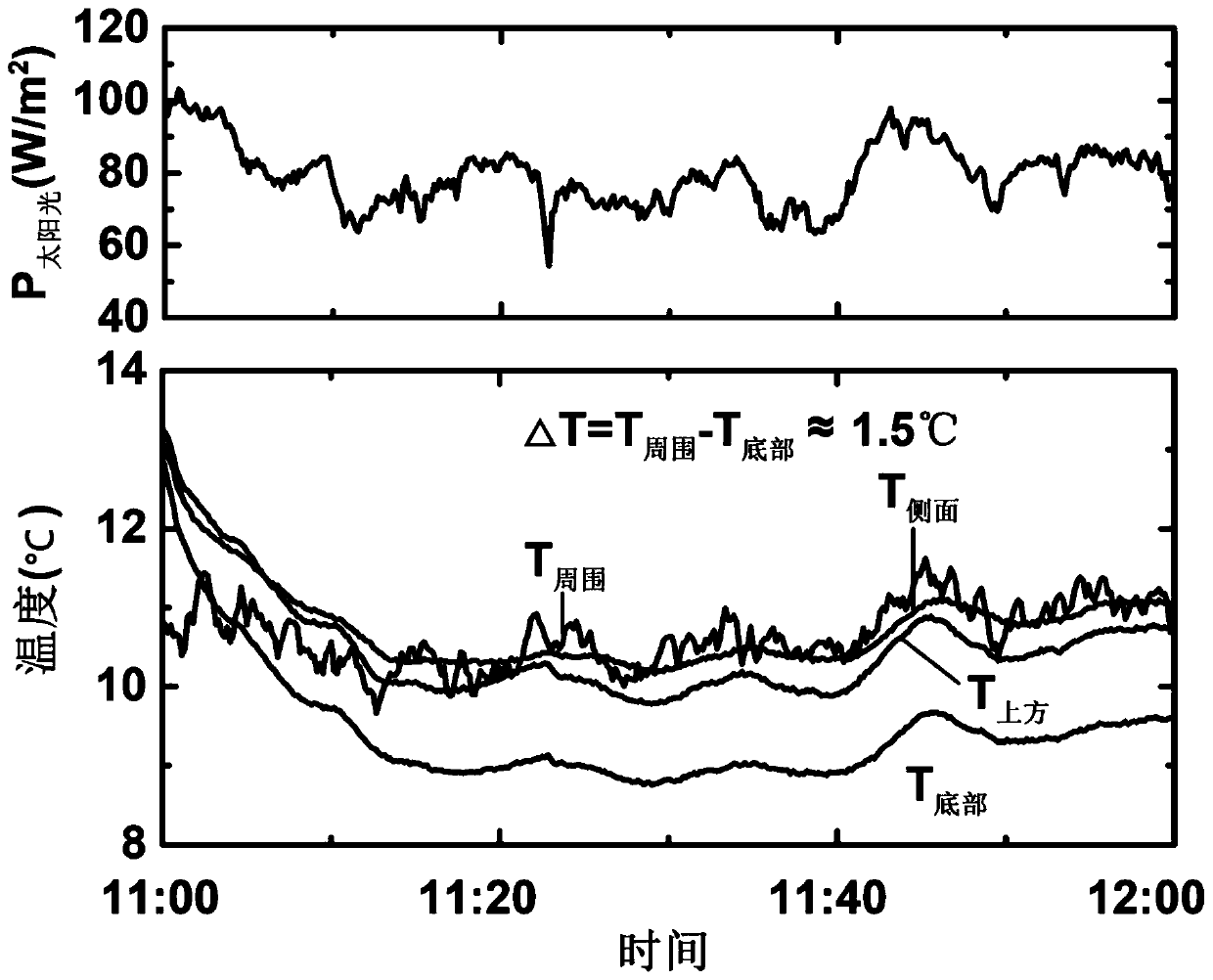

[0041] The radiant refrigeration fiber membrane obtained above is placed in such as figure 2 The radiation cooling test is carried out in the temperature measuring device shown, and the ambient temperature outside the device and the temperature on the top, bottom and side of the sample film are measured simultaneously with a thermocouple, and the temperature drop curve changing with time is obtained as follows: Figure 4 shown. from Figure 4 It can be seen that the above-mentioned fiber membrane is at an average of about 80W / m 2 Under the sun's rays, the temperature of the surface of the object close to the fiber membrane is about 1.2°C lower than the ambient temperature outside the device, which i...

Embodiment 3

[0043] Weigh 2.1g PA6 slices and dissolve them in 7.9g formic acid solution, stir evenly to completely dissolve PA6 to obtain 21% PA6 solution, then weigh 0.42g SiO 2 The microspheres were added to the PA6 solution, stirred by magnetic force for 4h, so that the SiO 2 The microspheres are uniformly dispersed in it to obtain SiO 2 Dosage is 20% mixed dispersion liquid standby, all the other are identical with embodiment 1, obtain PA6 / SiO 2 The radiative cooling fiber membrane is ready for use, with a thickness of 20 μm.

[0044] The radiant refrigeration fiber membrane obtained above is placed in such as figure 2 The radiation cooling test is carried out in the temperature measuring device shown, and the ambient temperature outside the device and the temperature on the top, bottom and side of the sample film are measured simultaneously with a thermocouple, and the temperature drop curve changing with time is obtained as follows: Figure 5 shown. from Figure 5 It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com