Method for preparing polytetrafluoroethylene superfine fiber

A polytetrafluoroethylene, ultra-fine fiber technology, used in fiber processing, spinning solution preparation, single-component halogenated hydrocarbon rayon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the preparation example of polytetrafluoroethylene superfine fiber

[0029] a. Preparation of spinning solution

[0030] First, 10.9 grams of polyvinyl alcohol was added into 88.1 grams of water, and heated and mechanically stirred to completely dissolve it to obtain an aqueous solution of polyvinyl alcohol. The used polyvinyl alcohol is a commercially available product, the degree of polymerization is 1700-1800, and the degree of alcoholysis is 88%-99%. To adjust the volatility of this solution, add 1 g of ethanol during stirring to make ethanol / water solution of polyvinyl alcohol. The ethanol / water solution of the obtained polyvinyl alcohol and the weight percent concentration are 60%, and the polytetrafluoroethylene particle size is 200nm polytetrafluoroethylene concentrated dispersion emulsions are mixed uniformly by weight ratio 1: 1, after static defoaming, obtain spinning solution;

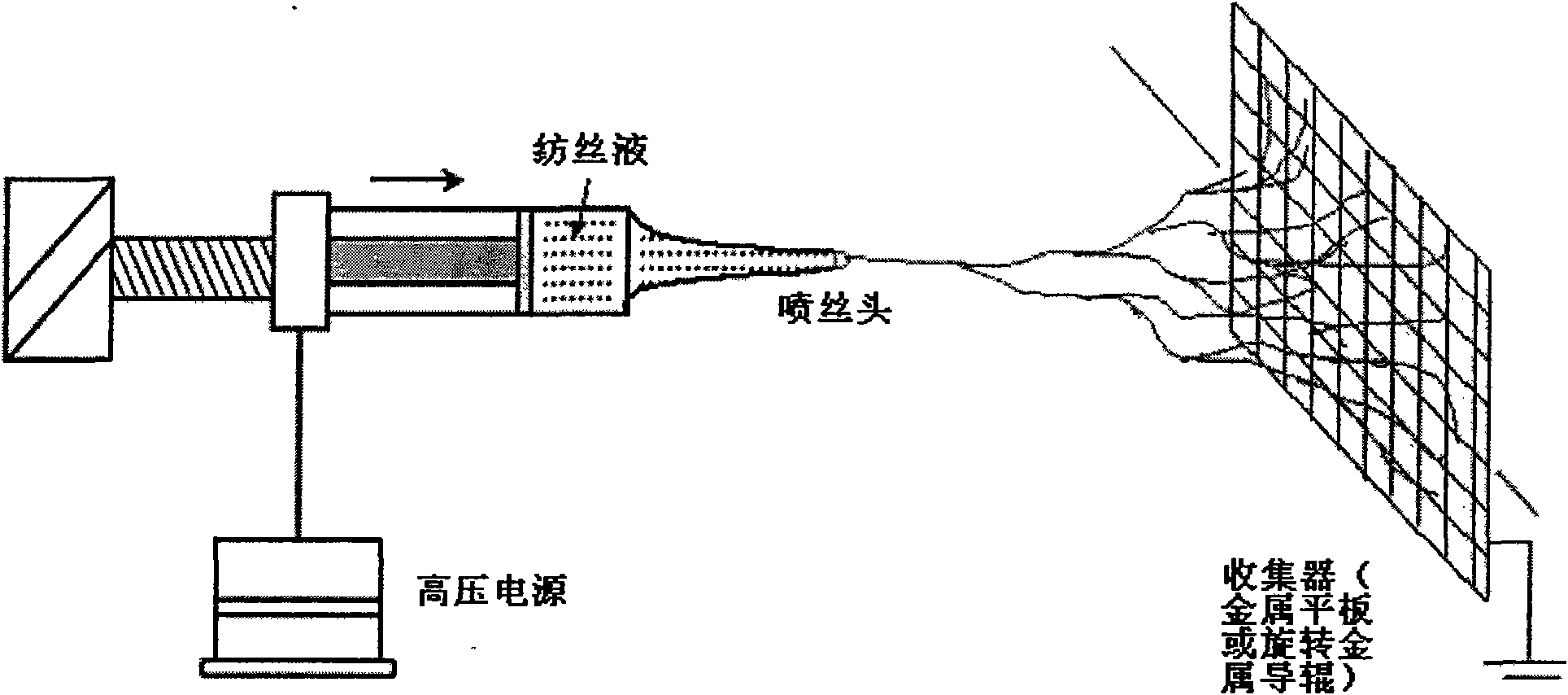

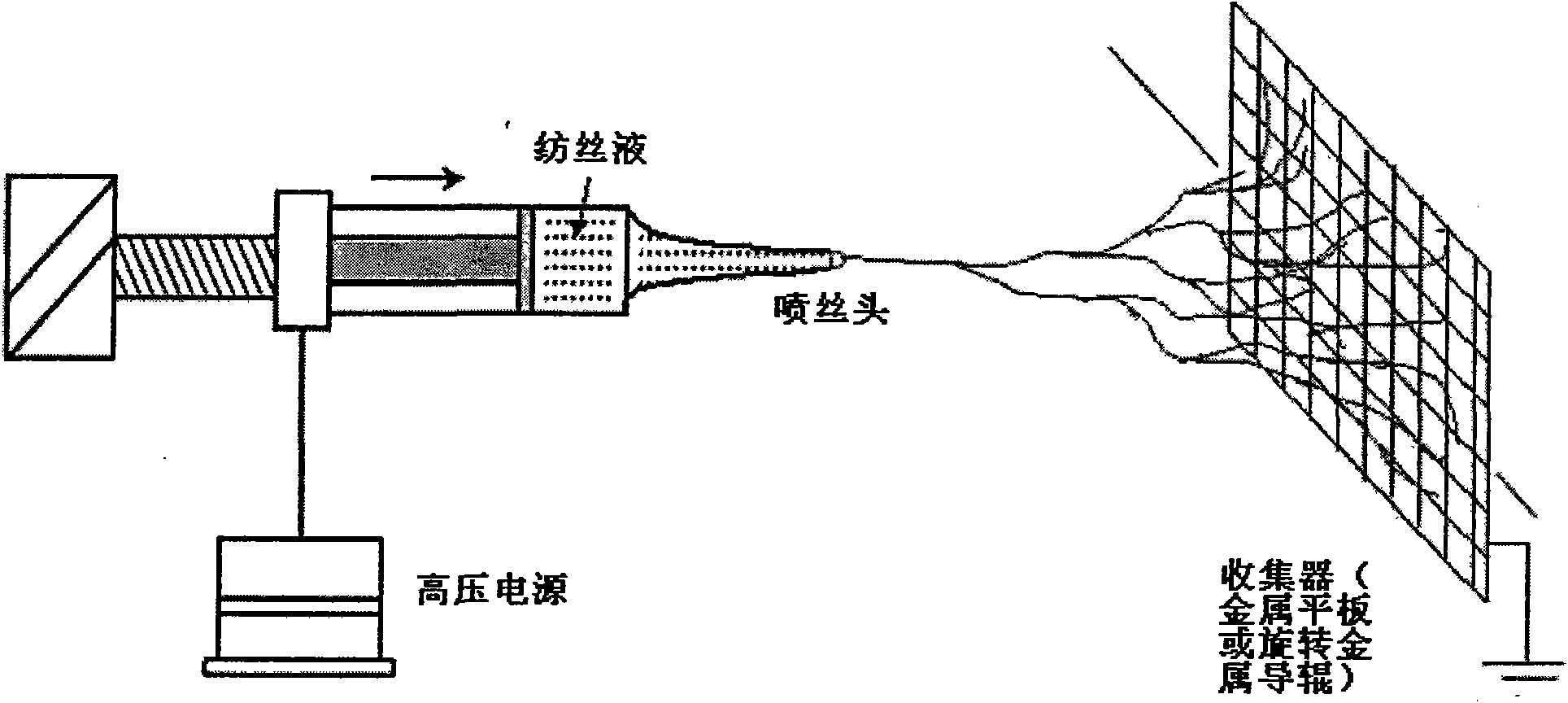

[0031] b. Electrospinning

[0032] The spinning liquid that st...

Embodiment 2

[0035] Embodiment 2, the preparation example of polytetrafluoroethylene superfine fiber

[0036] a. Preparation of spinning solution

[0037] First, 10 grams of polyvinyl alcohol was added into 90 grams of water, and heated and mechanically stirred to completely dissolve it to obtain an aqueous solution of polyvinyl alcohol. The aqueous solution of polyvinyl alcohol and the polytetrafluoroethylene concentrated dispersion emulsion with a weight percentage concentration of 60% and a polytetrafluoroethylene particle size of 250nm are mixed uniformly in a weight ratio of 1:1, and left to stand for defoaming to obtain spinning liquid;

[0038] b. Electrospinning

[0039] The spinning solution that step A obtains is injected into electrospinning device (such as figure 1 In the feeding device as shown), adjust the feeding rate of the spinning solution to be 100ul / min; the distance between the spinneret of the feeding device and the grounded collector is 20cm; turn on the high volt...

Embodiment 3

[0042] Embodiment 3, the preparation example of polytetrafluoroethylene superfine fiber

[0043] a. Preparation of spinning solution

[0044] First, 6 grams of polyvinyl alcohol was added into 93 grams of water, and heated and mechanically stirred to completely dissolve it to obtain an aqueous solution of polyvinyl alcohol. To adjust the volatility of the solution, add 1 g of ethanol during stirring to make an ethanol / water solution of polyvinyl alcohol. The aqueous solution of the prepared polyvinyl alcohol and the polytetrafluoroethylene concentrated dispersion emulsion with a weight percentage concentration of 60% and a polytetrafluoroethylene particle size of 10 nm are mixed uniformly in a weight ratio of 1:1, and left standing for defoaming to obtain a spinning liquid;

[0045] b. Electrospinning

[0046] The spinning solution that step A obtains is injected into electrospinning device (such as figure 1 In the feeding device as shown), adjust the feeding rate of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com