Device and method for preparing regular arranged macromolecular nano-fibre

A nanofiber and macromolecule technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of complex receiving device, large external influence on electric field control, and inability to obtain a large-area ordered structure with regular arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

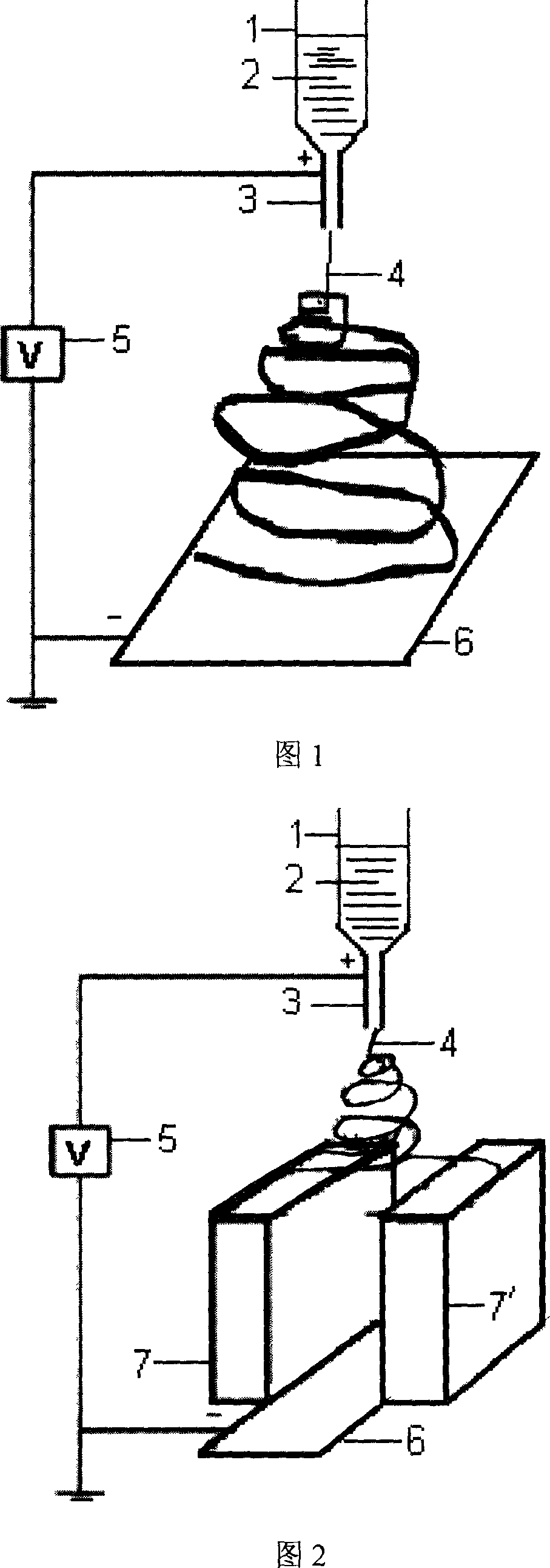

[0040]With reference to Fig. 2, make a magnetron electrospinning device of the present invention. The device consists of a spinneret 1 for containing the polymer solution 2, and a nozzle 3 is installed at the end of the spinneret 1, the nozzle 3 is a ground medical syringe needle, the syringe needle and the high-pressure generator 5 The positive poles are connected as anodes; 2 NdFeB permanent magnets are used as the first permanent magnet 7 and the second permanent magnet 7', an aluminum foil 6 is arranged between the first permanent magnet 7 and the second permanent magnet 7', and the 2 permanent magnets The distance between them is 5 cm; a piece of aluminum foil 6 is connected to the negative pole of the high voltage generator 5 as a cathode, and the cathode is grounded at the same time; the nozzle 3 is arranged directly above the aluminum foil 6 .

[0041] Compared with the traditional electrospinning device, the magnetron electrospinning device has two more magnets, and t...

Embodiment 2

[0043] In this embodiment, the device of Embodiment 1 is used to carry out the magnetron electrospinning method for preparing polyvinyl alcohol regularly arranged nanofibers of the present invention, and the specific steps are as follows:

[0044] Dissolving polyvinyl alcohol in distilled water, heating to 70° C., magnetically stirring for 2 hours, and then stirring at normal temperature for 6 hours to obtain a 5-20 wt % transparent PVA solution. Add 0.05wt% magnetic nano-particles in the solution, such as nano-Fe 3 o 4 Put the powder into the polymer solution, and ultrasonically disperse for 24 hours. The PVA solution prepared by magnetization was stored in a refrigerator at 4 degrees, and then ultrasonicated for 20 minutes before electrospinning. During magnetron electrospinning, the prepared PVA magnetized polymer solution 2 is contained in the spinneret 1, the distance between the nozzle and the upper surface of the magnet is 10 cm, the nozzle 3 is connected to the posit...

Embodiment 3

[0047] In the device of Example 1, the method for preparing polystyrene regularly arranged micro-nano fibers is the same as that of Example 2, and the specific differences are as follows:

[0048] Polystyrene was dissolved in dimethylformamide (DMF), stirred at room temperature for 8 hours to obtain a 10-30 wt% transparent PS solution. Add 0.08wt% magnetic nano-particles such as nano-Fe to the solution 3 o 4 Powder, ultrasonically dispersed for 24 hours. The magnetized PS solution was stored in a 4°C refrigerator, and then sonicated for 20 minutes before electrospinning. During magnetron electrospinning, put the solution into the syringe of the electrospinning device, the distance between the nozzle and the upper surface of the magnet is 10-20cm, the spinning voltage is 10-30kV, and the distance between the magnets is 10cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com