Millet granule processing method

A technology of millet and pellets, applied in the field of technology, can solve problems such as time-consuming, laborious, and restrictive, and achieve the effects of flexible and adjustable grain number, reducing damage, and reducing the difficulty of sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

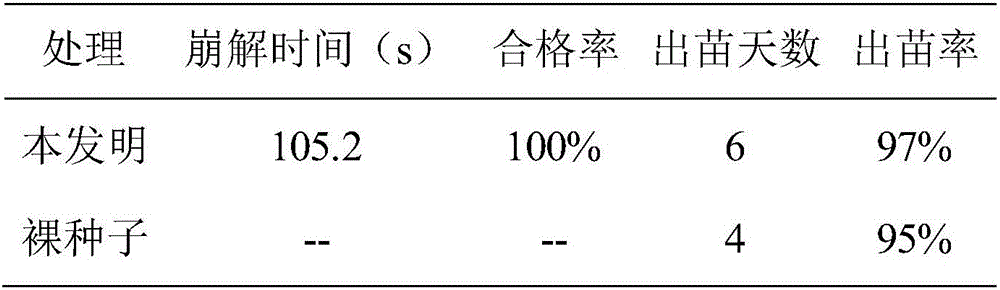

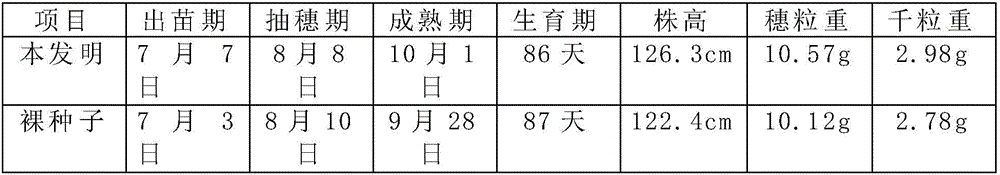

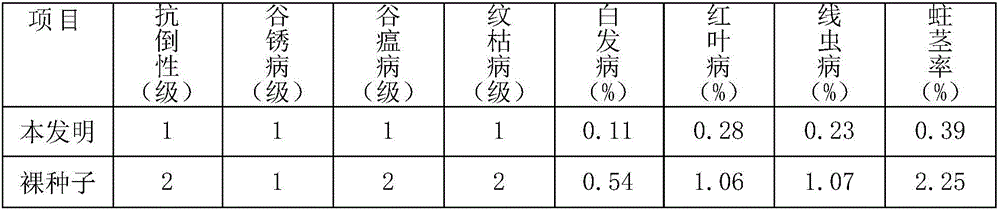

Examples

Embodiment 1

[0034] Take the treatment of 10 kg of seeds as an example, millet variety: Henggu No. 13.

[0035] (1) Preparation of film-forming agent: get a certain amount of polyvinyl alcohol and join in a certain amount of hot water, add while stirring, and be mixed with a concentration of 0.2% polyvinyl alcohol film-forming agent.

[0036] (2) Preparation of filling material: air-dry laterite, peat soil, and vermiculite naturally, grind them mechanically, pass the three through a soil sieve with an aperture of 1 mm, remove organic residues such as plant roots and leaves, and then take 50 kg of the three, 2.5kg, 2.5kg mix.

[0037] (3) Preparation of granulating agent: add 8.5 kg of film-forming agent prepared in (1) to the filling material prepared in (2), and stir evenly.

[0038] (4) Preparation of pellet powder: including attapulgite, fungicides, insecticides, potassium dihydrogen phosphate, etc. Wherein the insecticide is containing phoxim 60g; the bactericide is 20g of 35% metala...

Embodiment 2

[0044] (1) The preparation of the film-forming agent and the filler are the same as in Example 1.

[0045] (2) Preparation of granulating agent: mix 9.6 kg of filler and film-forming agent prepared in (1) and stir evenly.

[0046] (3) preparation of pellet powder: the same as the scheme of embodiment 1.

[0047] (4) Preparation of preliminary millet aggregates: send the selected seeds into the coating machine, use the film-forming agent prepared in (1) for coating, and send them to the particle control machine after natural air drying, according to the seed germination rate, The number of plants in each hole determines that the number of grains per group is 6;

[0048] Send the seeds to the spherical mold at one time through the conveying device, combine every 6 pieces together to form a seed mass, then press the seed mass and the granulating agent prepared in (2) together to form a seed mass, and then dry , the temperature was controlled at 35°C to obtain preliminary millet...

Embodiment 3

[0052] (1) The preparation of the film-forming agent and the filler are the same as in Example 1.

[0053] (2) Preparation of granulating agent: Mix 10.7 kg of filler and film-forming agent prepared in (1) and stir evenly.

[0054] (3) preparation of pellet powder: the same as the scheme of embodiment 1.

[0055] (4) Preparation of preliminary millet aggregates: send the selected seeds into the coating machine, use the film-forming agent prepared in (1) for coating, and send them to the particle control machine after natural air drying, according to the seed germination rate, The number of plants in each hole determines that the number of grains per group is 7;

[0056] The seeds are sent to the oblong mold at one time through the conveying device, and every 7 grains are combined to form a seed mass, and then the seed mass and the granulating agent prepared in (2) are pressed together to form a seed mass, and then Drying, the temperature is controlled at 30 ° C, to obtain pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com