Forming process of brick in composite structure

A molding process and brick molding technology, which is applied in the field of composite structural brick preparation, can solve problems such as difficulty in fabric distribution, and achieve the effects of reducing mold costs, large operable space, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

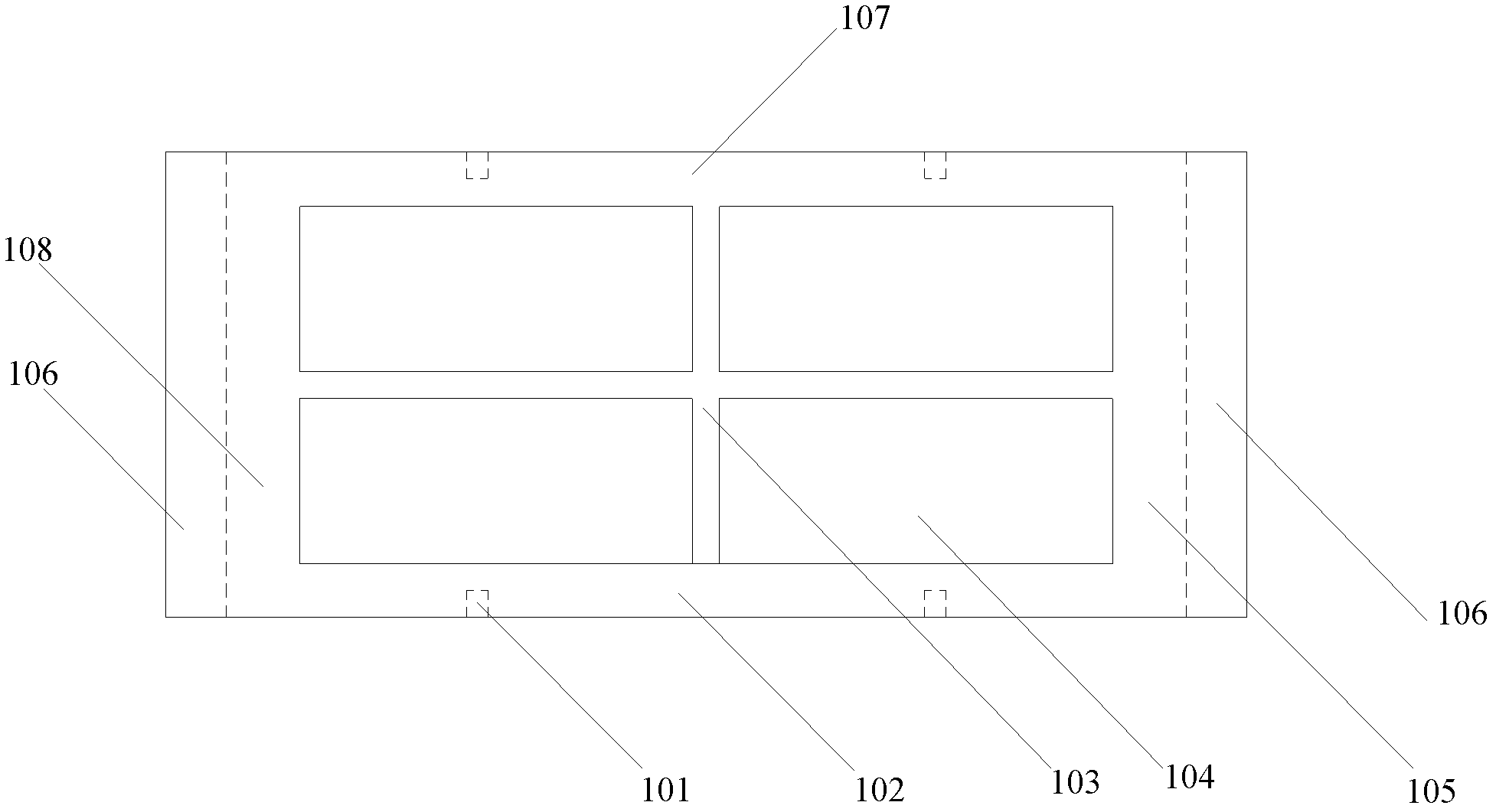

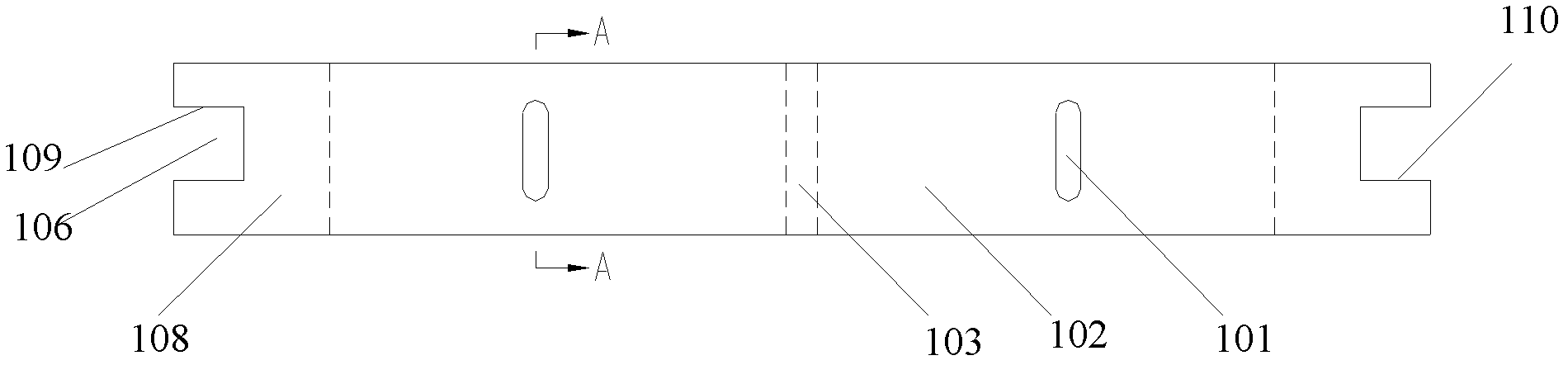

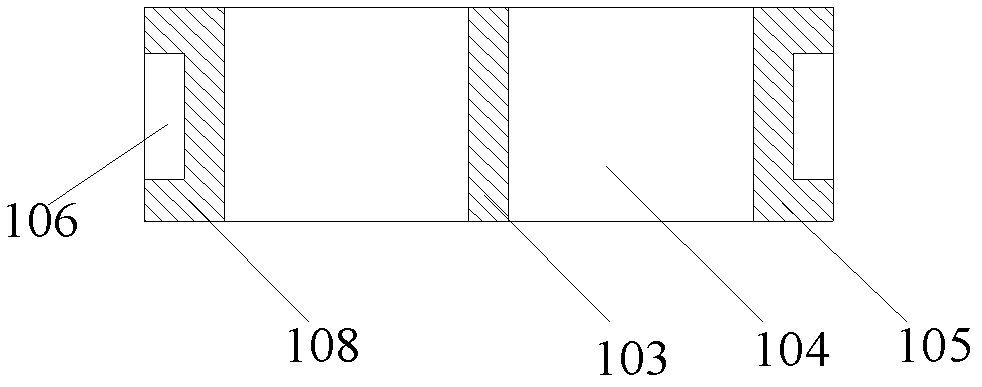

[0085] The technical solutions and beneficial effects of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0086] The process of the present invention can realize the formation of conforming structural bricks on the system provided by the present invention, and avoid the contamination between different interlayer materials, including the following steps:

[0087] S1: The brick forming mold is sent to the first forming equipment and the first distributing device;

[0088] S2: The first distributing device disperses the brick forming mold, and after the distributing is completed, the first forming device pre-presses;

[0089] S3: After pre-pressing, the brick forming mold carries the brick blanks to the second forming equipment and the second distributing device by the first continuous conveying device;

[0090] S4: The second distributing device distributes the mold with the brick blank again, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com