Woven 2D+2.5D profiling fabric composite fabric and forming method thereof

A molding method and fabric technology, applied in the direction of fabrics, textiles, textiles, and papermaking, can solve the problems of low densification, low volume content, and high labor costs, and achieve high mechanization, good uniformity, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

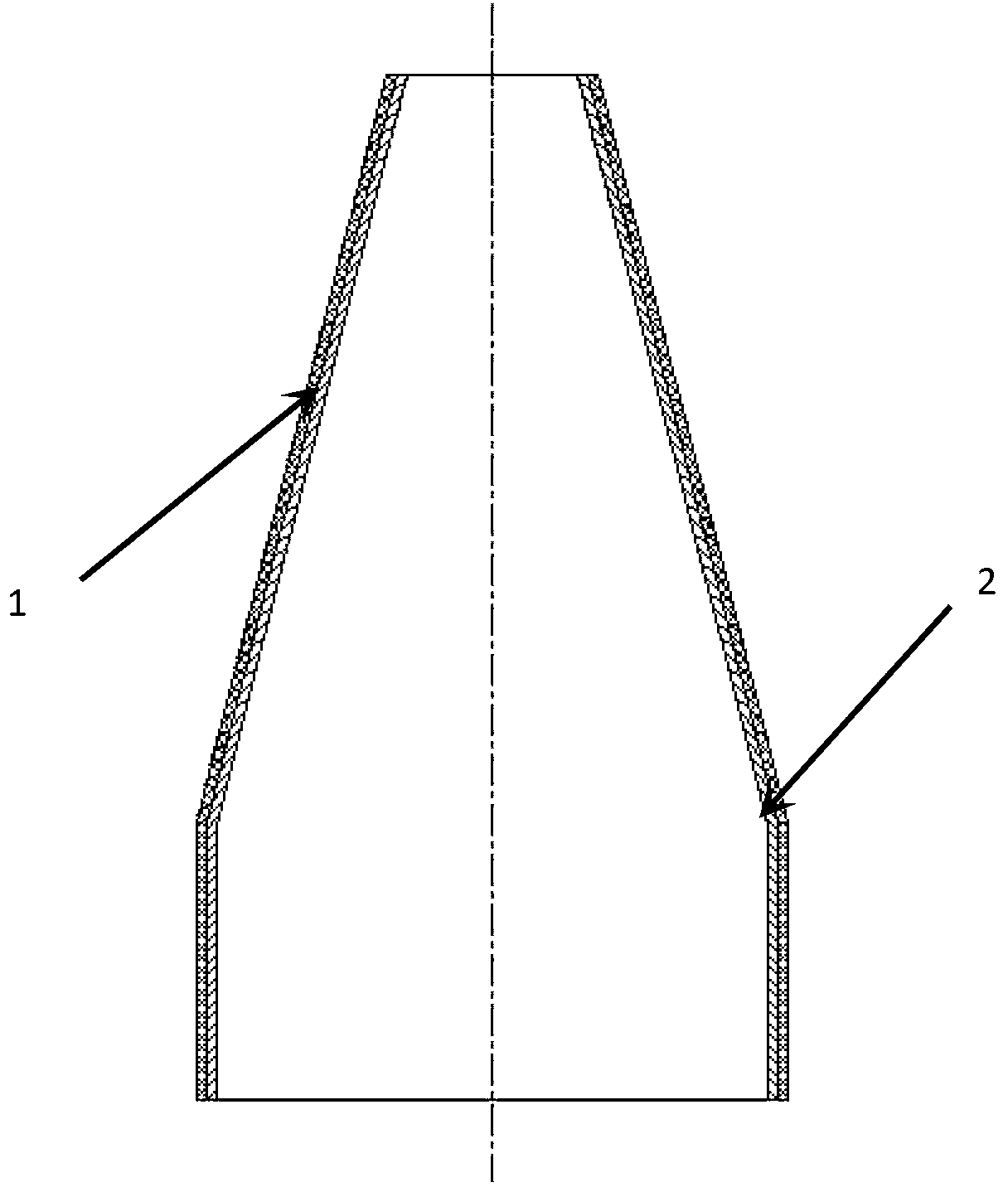

[0026] with tapered fabric (see eg image 3 ) as an example, the inner diameter of the large section of the fabric is 220.4mm, the inner diameter of the small section is 67.5mm, the height of the tapered section is 300mm, the length of the straight section is 110mm, and the overall thickness is 8mm.

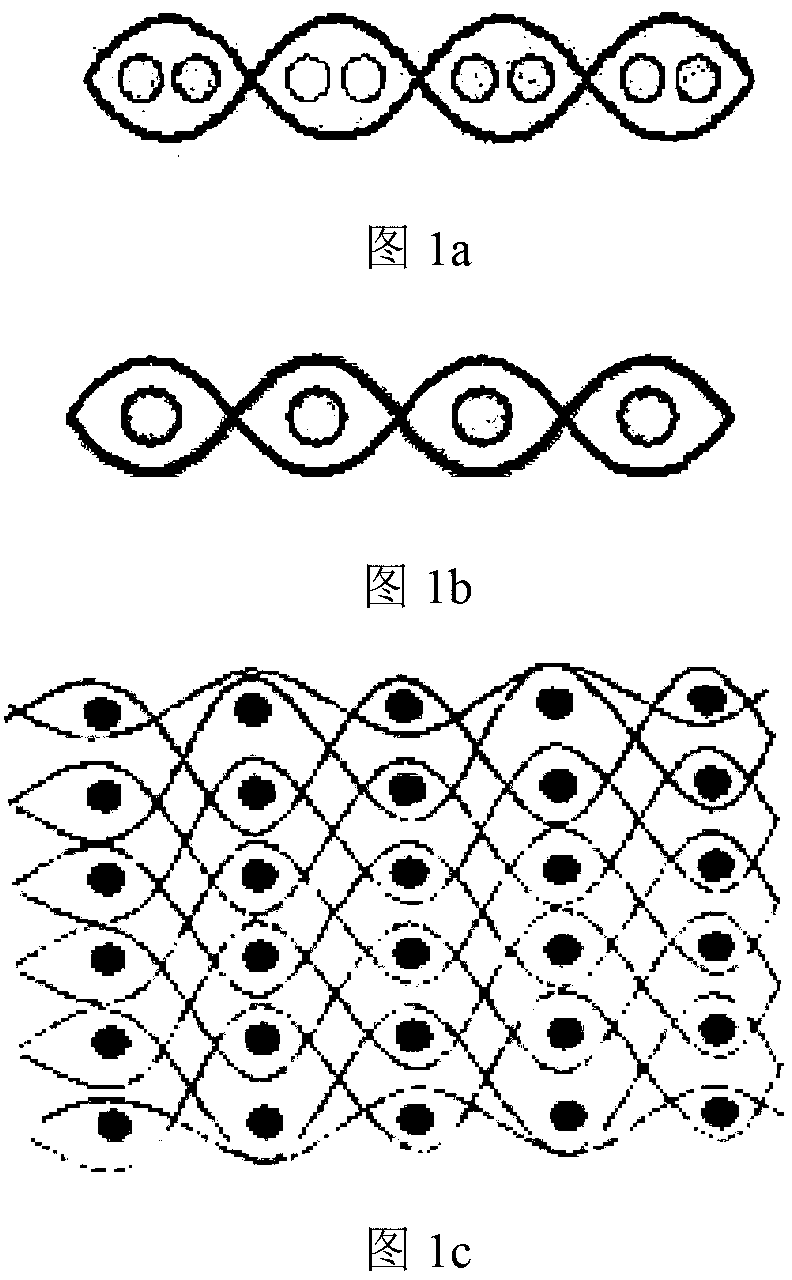

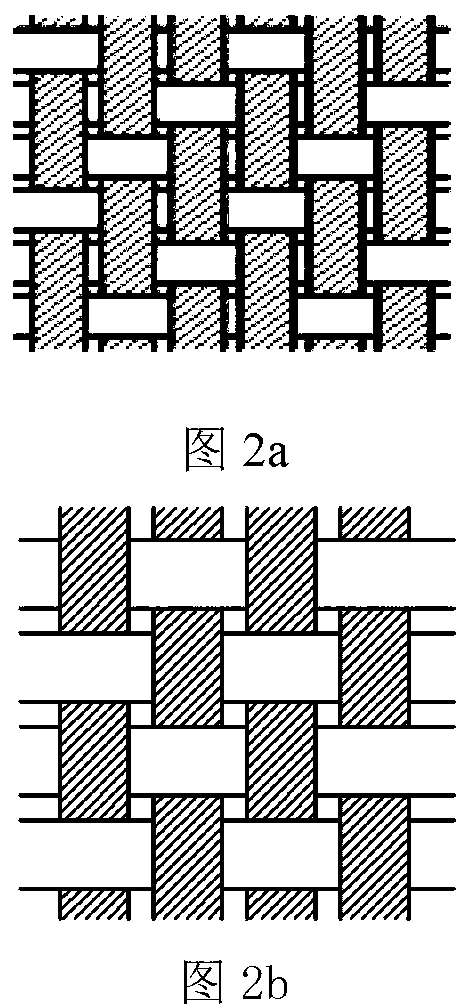

[0027] The inner 4mm thickness of the fabric is 2.5D shallow cross-bending structure (see figure 1 c) The fiber is made of 190Tex quartz fiber; it is designed as a 2-layer shallow cross-bending structural unit cover, and the number of warp yarn layers in each unit cover is 5 layers; the warp yarn density is 10.0 yarns / cm, and the weft yarn density is 4.0 yarns / cm. Fabric outer 4mm thickness 2 / 2 twill construction (see figure 1 a), the fiber uses 72Tex quartz fiber; it is designed as a 21-layer 2 / 2 twill structure unit cover; the warp yarn density is 16.0 yarns / cm, and the weft yarn density is 12.0 yarns / cm.

[0028] The specific process implementation steps of the inner 4mm sha...

Embodiment 2

[0055] Tubular fabrics (see e.g. Figure 4 ) as an example, the inner diameter of the fabric is 285mm, the height is 410mm, and the overall thickness increases from 8.3mm to 9.8mm in the length direction.

[0056] The fabric is designed as a sandwich structure: the inner 1.8mm thickness adopts a plain weave structure (see figure 1 b), the fiber is made of 3K carbon fiber; the middle 5mm thickness adopts a shallow cross-bending structure (see figure 1 c), the fiber is made of 6K carbon fiber; the outer layer is 3mm thick and has a 2 / 2 twill structure (see figure 1 a), the fiber uses 3K carbon fiber.

[0057] Inner 1.8mm: plain weave structure, warp yarn density 16.0 yarns / cm, weft yarn density 12.0 yarns / cm, 6-layer unit cover.

[0058] Middle 5mm: shallow cross-bending structure, warp yarn density 8.0 yarns / cm, weft yarn density 3.0 yarns / cm, composed of 1-layer unit cover.

[0059] Outer layer 3mm: 2 / 2 twill weave structure is easy to achieve slight difference in fabric o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com