Cellulose/tannin hydrogel and preparation method thereof

A cellulose and hydrogel technology, applied in the field of materials, can solve problems such as influence, influence on tannin fixation effect, tannin shedding, etc., and achieve the effects of strong operability, green dissolution process, and simple cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

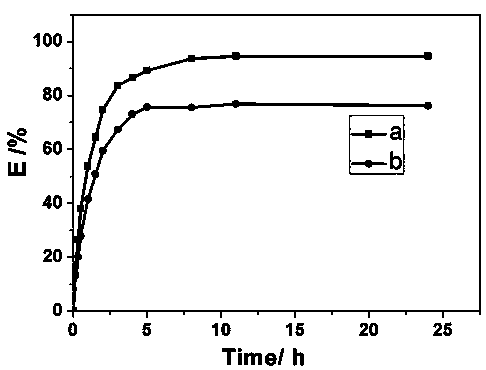

Image

Examples

Embodiment 1

[0029] The invention relates to a cellulose / tannin hydrogel, which is a product obtained after cross-linking reaction is carried out by adding a cross-linking agent epichlorohydrin to a mixed solution in which bayberry tannin and cellulose are dissolved. The solvent of mixed solution is made of urea / sodium hydroxide / water; The concentration of cellulose in mixed solution is 3wt%, and the mass ratio of tannin and cellulose is 1: 5; The volume mass ratio of epichlorohydrin and mixed solution is 0.5ml: 10g.

[0030] Its preparation method comprises the following steps:

[0031] (1) Dissolving cellulose in a solvent composed of urea / sodium hydroxide / water at low temperature to obtain a cellulose solution;

[0032] (2) Add tannin to the cellulose solution, place it in an ice bath and disperse evenly with ultrasound to obtain a mixed solution of tannin and cellulose;

[0033] (3) Add a cross-linking agent to the mixed solution obtained in step (2) for cross-linking react...

Embodiment 2

[0036] The invention relates to a cellulose / tannin hydrogel, which is a product obtained after cross-linking reaction is carried out by adding a cross-linking agent epichlorohydrin to a mixed solution in which bayberry tannin and cellulose are dissolved. The solvent of the mixed solution is composed of urea / sodium hydroxide / water; the concentration of cellulose in the mixed solution is 4.5wt%, and the mass ratio of tannin to cellulose is 7:5; the volume-to-mass ratio of epichlorohydrin to the mixed solution It is 1ml: 10g.

[0037] Its preparation method comprises the following steps:

[0038] (1) Dissolving cellulose in a solvent composed of urea / sodium hydroxide / water at low temperature to obtain a cellulose solution;

[0039] (2) Add tannin to the cellulose solution, place it in an ice bath and disperse evenly with ultrasound to obtain a mixed solution of tannin and cellulose;

[0040] (3) Add a cross-linking agent to the mixed solution obtained in step (2) for ...

Embodiment 3

[0043] The invention relates to a cellulose / tannin hydrogel, which is a product obtained after a crosslinking reaction of a condensed tannin, a cellulose mixed solution and a crosslinking agent epichlorohydrin. The solvent of the mixed solution is composed of urea / sodium hydroxide / water; the concentration of cellulose in the mixed solution is 2.5wt%, and the mass ratio of tannin to cellulose is 1:5; the volume-to-mass ratio of epichlorohydrin to the mixed solution It is 0.7ml: 10g.

[0044] Its preparation method comprises the following steps:

[0045] (1) Dissolving cellulose in a solvent composed of urea / sodium hydroxide / water at low temperature to obtain a cellulose solution;

[0046] (2) Add tannin to the cellulose solution, place it in an ice bath and disperse evenly with ultrasound to obtain a mixed solution of tannin and cellulose;

[0047] (3) Add a cross-linking agent to the mixed solution obtained in step (2) for cross-linking reaction: first place the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com