Fe-Si-B amorphous alloy-copper laminated composite material and preparation method thereof

A technology of amorphous alloys and composite materials, which is applied in the direction of metal layered products, non-electric welding equipment, metal processing equipment, etc., can solve the problem of inability to prepare large-sized amorphous alloys, achieve good high-frequency shielding effect, and broaden the application range , The effect of excellent low-frequency magnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

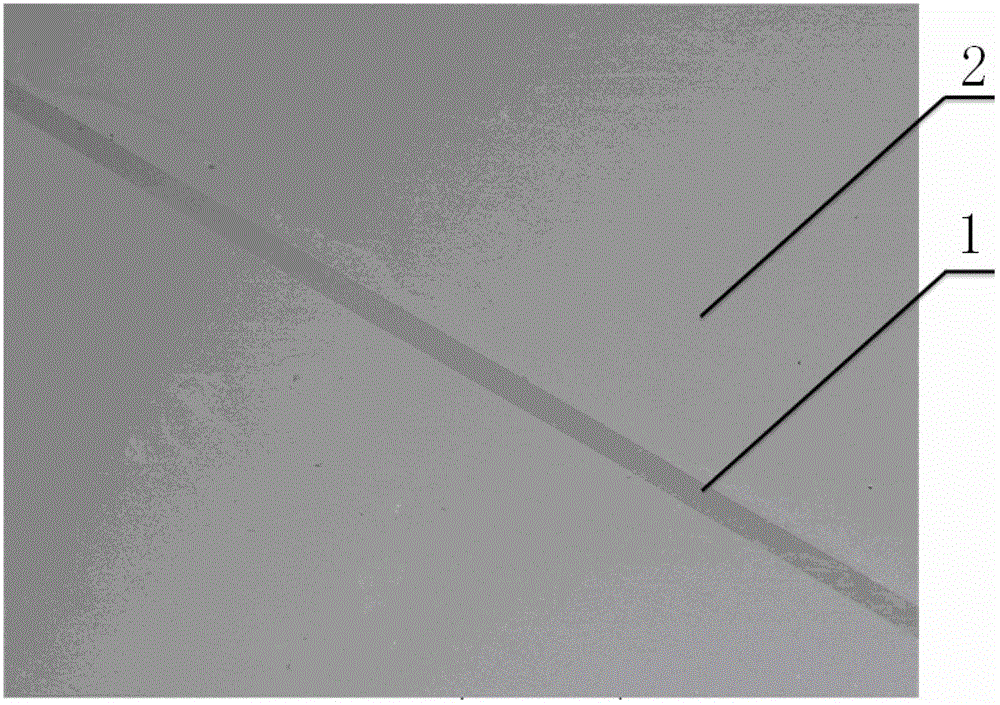

[0025] This embodiment is a Fe-Si-B amorphous alloy-copper layered composite material. The Fe-Si-B amorphous alloy-copper layered composite material is composed of one layer of Fe-Si-B amorphous strip and two layers of copper, and the Fe-Si-B amorphous strip is sandwiched between between the two layers of copper.

[0026] The Fe-Si-B amorphous strip used in this embodiment is national standard 1K101; the copper used is T2 pure copper rod.

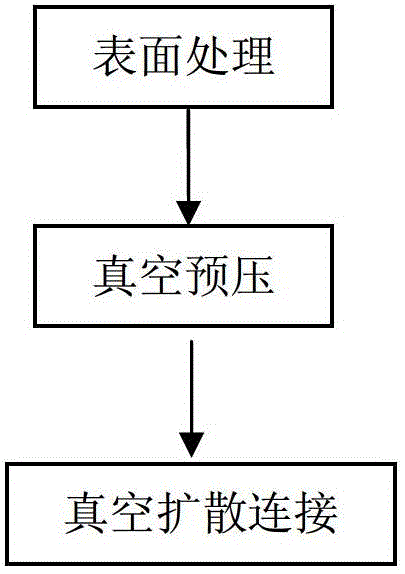

[0027] This embodiment also proposes a method for preparing Fe-Si-B amorphous alloy-copper layered composite material, comprising the following steps:

[0028] Step 1, surface treatment: grinding and polishing the Fe-Si-B amorphous and copper surfaces to be connected, and removing oxides on the copper surface with 5% dilute hydrochloric acid, and then ultrasonically cleaning them in ethanol and acetone for 1 min respectively.

[0029] Step 2, pre-press. The processed Fe-Si-B amorphous alloy was placed between two copper rods to form a sa...

Embodiment 2

[0034] This embodiment is a Fe-Si-B amorphous alloy-copper layered composite material. The Fe-Si-B amorphous alloy-copper layered composite material is composed of one layer of Fe-Si-B amorphous strip and two layers of copper, and the Fe-Si-B amorphous strip is sandwiched between between the two layers of copper.

[0035] The Fe-Si-B amorphous strip used in this embodiment is national standard 1K101; the copper used is T2 pure copper rod.

[0036] This embodiment also proposes a method for preparing Fe-Si-B amorphous alloy-copper layered composite material, comprising the following steps:

[0037] Step 1, surface treatment: grinding and polishing the Fe-Si-B amorphous and copper surfaces to be connected, and removing oxides on the copper surface with 5% dilute hydrochloric acid, and then ultrasonically cleaning them in ethanol and acetone for 1 min respectively.

[0038] Step 2, pre-press. The processed Fe-Si-B amorphous alloy was placed between two copper rods to form a sa...

Embodiment 3

[0043] This embodiment is a Fe-Si-B amorphous alloy-copper layered composite material. The Fe-Si-B amorphous alloy-copper layered composite material is composed of one layer of Fe-Si-B amorphous strip and two layers of copper, and the Fe-Si-B amorphous strip is sandwiched between between the two layers of copper mentioned above.

[0044] The Fe-Si-B amorphous strip used in this embodiment is the national standard 1K101; the copper used is a brass rod.

[0045] This embodiment also proposes a method for preparing Fe-Si-B amorphous alloy-copper layered composite material, comprising the following steps:

[0046] Step 1, surface treatment: grinding and polishing the Fe-Si-B amorphous and brass surfaces to be connected, and removing oxides on the brass surface with 5% dilute hydrochloric acid, and ultrasonic cleaning in ethanol and acetone for 1 min respectively.

[0047] Step 2, pre-press. The processed Fe-Si-B amorphous alloy was placed between two copper rods to form a sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com